Medtech

Equipment and Machinery

Bring the benefits of 3D printing to hospitals and beyond

3D printing is a proven technology in the medtech industry, benefiting the production of machinery and tools used in life science research labs, pharmaceutical production, hospitals, and beyond. Discover how you can take advantage of unmatched design freedom, enable mass customization across your product line, move from design to serial production quickly and affordably, and benefit from de-risked and sustainable supply chains.

Why choose 3D printing?

Sustainable supply chains

With 3D printing and a digital inventory, you can eliminate stock risk through just-in-time, on-demand manufacturing. This reduces waste and the total cost of ownership, resulting in leaner operations.

Operational efficiency

Reduce the production, assembly, and maintenance costs of tools by redesigning them for 3D printing. Improve the performance of production parts or merge several components into one to optimize output.

Market-ready innovation

Create truly unique solutions and enable customization across your product line. With a significantly shorter time-to-market, you can develop new products and respond to the shifting demands of your industry faster than ever.

Cost-effective small series production

With no minimum order quantities, manufacturing with 3D printing can start at a series of one. Produce unique components on demand and eliminate the need for tooling or build high-quality masters for vacuum casting.

Why choose Materialise?

Ideal materials

PA 12 Medical-Grade (PA 2201)

Technology

Selective laser sintering

Description

PA 12 Medical-Grade offers high strength, chemical resistance, and detail resolution, making it ideal for high-quality and fully-functional biocompatible plastic parts for settings such as operating rooms. This material is subjected to testing for cytotoxicity, sensitization, irritation, acute systemic toxicity, and material-mediated pyrogenicity.

Key characteristics

- Biocompatible material

- High strength and stiffness

- Good chemical resistance

- High selectivity and detail resolution

- Max part dimensions: 170 x 215 x 320 mm

PA 12 (SLS)

Technology

Selective laser sintering

Description

PA 12 (SLS) is a general-purpose material that offers excellent long-term stability and good chemical resistance, making it suitable for functional prototypes and end-use parts, as well as consumer goods.

Key characteristics

- Strong, general-purpose material printed without a support structure

- High strength and stiffness

- High chemical, mechanical, and thermal resistance

- Fast Lane service available for online orders of PA 12 (SLS) – Normal finish

- Max part dimensions: 630 x 330 x 550 mm

- Max part dimensions (Fast Lane orders): 270 x 270 x 270 mm

PA 2210 FR

Technology

Selective laser sintering

Description

PA 2210 FR is a high-performance, UL Blue Card-certified polyamide containing a halogen-free flame retardant. Excellent long-term stability and good chemical resistance make it ideal for functional prototypes or end-use parts.

Key characteristics

- Strong material printed without a support structure

- Flame retardant — UL Blue Card-certified (UL 94 rating of V-0 at 3 mm wall thickness), CS/FAR 25.853 compliant

- High chemical, mechanical, and thermal resistance

- Max part dimensions: 280 x 280 x 550 mm

ABS-like Polyurethanes

Technology

Vacuum casting

Description

Offering a range of different material properties, our ABS-like polyurethanes can be used with silicone molds to produce high-quality prototypes or small series of end-use parts.

Key characteristics

- Excellent surface and detail, with injection-molded look and feel

- Flame-retardant, food-safe, and UV-stable materials available

- Cost-effective way to produce prototypes or small series of end-use parts

- Max part dimensions: 1,900 x 900 x 750 mm (maximum part volume: 10 liters)

Stainless Steel (SS316L)

Technology

Metal 3D printing

Description

Stainless steel (SS316L) is a low-carbon stainless steel alloy that offers excellent strength, high corrosion resistance and ductility, and good thermal properties, making it suitable for general prototyping.

Key characteristics

- Excellent strength

- High corrosion, temperature, and chemical resistance

- High ductility

- Suitable for food-safe applications

- Max part dimensions: 250 x 250 x 305 mm

Titanium (Ti₆Al₄V)

Technology

Metal 3D printing

Description

Ti₆Al₄V is a lightweight titanium alloy with excellent mechanical strength and superior corrosion resistance, making it ideal for functional prototypes and high-performance end-use parts.

Key characteristics

- Excellent mechanical properties

- Lightweight, with a high strength-to-weight ratio

- High corrosion and temperature resistance

- Suitable for post-machining

- Max part dimensions: 250 x 250 x 305 mm

ABS-M30i

Technology

Fused deposition modeling

Description

Similar to ABS-M30 in strength, durability, and feature detail, ABS-M30i is biocompatible, making it ideal for applications in the food packaging, pharmaceutical, and medical device industries.

Key characteristics

- Biocompatible and ISO 10993 compliant

- High tensile, impact and flexural strength

- Very high dimensional accuracy

- Max part dimensions: 914 x 610 x 914 mm

PC-ISO

Technology

Fused deposition modeling

Description

This biocompatible polycarbonate material is known for its high strength and stiffness. Its versatility, durability, and dimensional stability make it ideal for everything from heavy-duty prototypes in industries like aerospace and automotive to small series of end-use medtech parts.

Key characteristics

- High strength and stiffness, ideal for parts exposed to constant stress and heavy loads

- Excellent heat resistance, making it suitable for use in high-temperature environments

- Good chemical resistance and dimensional stability

- Max part dimensions: 914 x 610 x 914 mm

Ultrasint TPU 90A-01

Technology

Multi Jet Fusion

Description

Ultrasint TPU 90A-01 combines durable elasticity with good wear and abrasion resistance, making it ideal for prototypes and end-use applications that require good shock absorption.

Key characteristics

- Rubber-like material printed without a support structure

- Durable elasticity with high elongation at break

- Good wear and abrasion resistance, and good shock absorption

- Max part dimensions: 370 x 274 x 375 mm

Typical applications

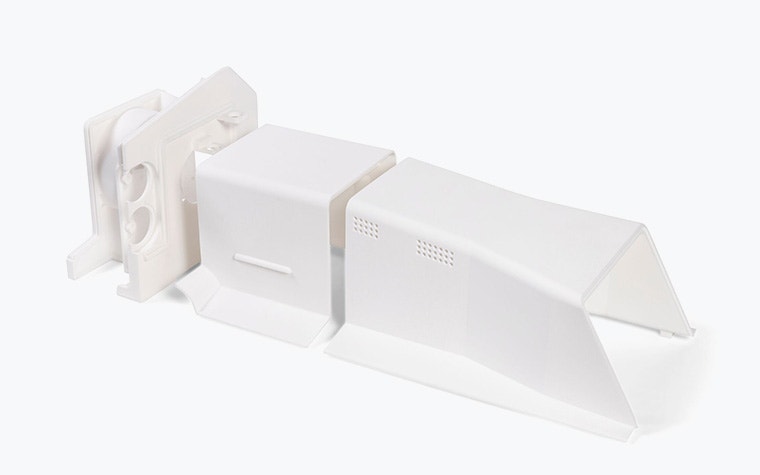

Housings and enclosures

Create unique and customized housings made fit for purpose with production-grade materials. With technologies like 3D printing and vacuum casting, you can adapt designs quickly and easily to keep up with changing requirements and produce the parts you need in short series.

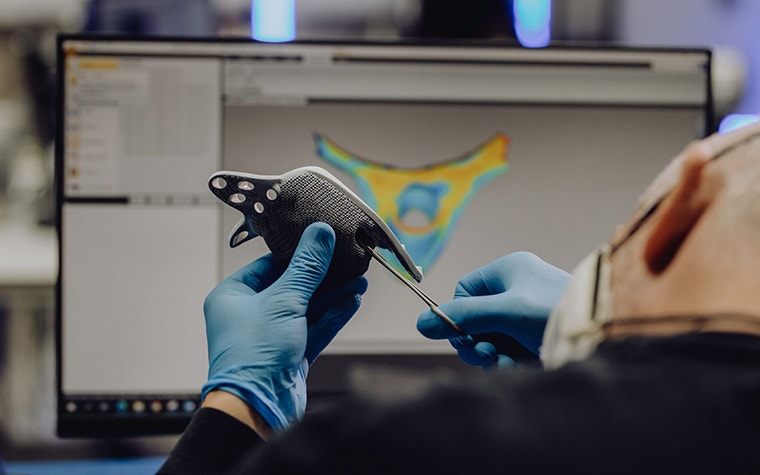

Technical components

Take advantage of 3D printing’s design freedom to create highly performant technical components made fit for purpose and performance.

Consumables

Single-use items such as microsurgery instruments benefit significantly from the finesse and flexibility of 3D printing. Key benefits for this application include no minimum order quantity, the ability to create personalized designs, and the intrinsic sustainability of additive manufacturing.

Handheld devices

For innovative handheld medical devices like HOYA’s Vision Simulator, going from prototype to final design can be an expensive and lengthy process. With 3D printing, you can reduce time-to-market, produce low volumes affordably, and easily adjust the design to respond to market feedback.

Our products and services

Ready to start your project with us? Discover our solutions, ideal for medtech.

Innovate and speed up your manufacturing in collaboration with our experts. Rely on our full range of in-house technologies suitable for all industries and applications.

Transform your product development cycle and get the best possible products to market faster. Get unbiased advice and dedicated support from teams committed to your success.

Get direct 24/7 access to the technologies and materials you need to bring your designs to life. Instant quotes, short lead-times, and easy checkout.

Build your success on a platform of software tools that efficiently manage and control the 3D printing process, allowing you to meet the highest standards of the most demanding industries.

Work with our experts to translate your business challenges into 3D printing opportunities and identify the applications that can help you meet your needs.

From bespoke surgical knee guides to true-to-life 3D-printed models of the human heart, our medical software and printing facilities are helping to bring personalized healthcare to everyone.

Discover the precise and seamless digital workflow designed by foot and ankle experts for foot and ankle experts based on scientific research

Inspiration

Get inspired for your next project with a look at how others have used 3D printing for medtech.

Header image: ©Sartorius AG

Housings and enclosures image: ©LMT Medical Systems GmbH