Material

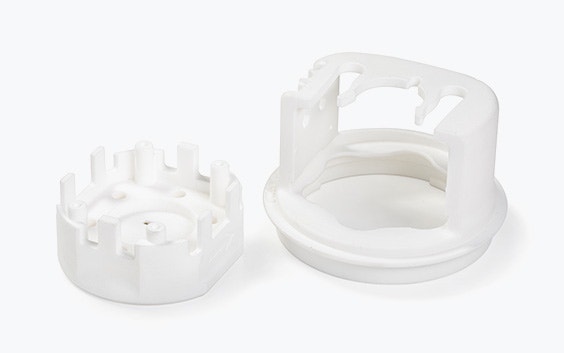

PA 12 Medical-Grade (PA 2201)

This version of PA 12 has high strength, chemical resistance, and detail resolution, making it ideal for medtech applications and devices requiring biocompatibility. This material is subjected to testing for cytotoxicity, sensitization, irritation, acute systemic toxicity, and material-mediated pyrogenicity. To ensure your biocompatibility requirements are met, talk to us about our manufacturing services for PA 12 Medical-Grade.

Technical specifications

| Maximum part dimensions | 170 x 215 x 320 mm |

| Standard accuracy | ±0.3% (with a lower limit of ±0.3 mm) |

| Layer thickness | 0.1 mm |

| Minimum wall thickness | 0.7 mm |

| Minimum detail size | 0.3 mm |

| Surface structure | Grainy structure |

Datasheet

| PARAMETER | VALUE | UNIT | METHOD |

| - | 0.93 | g/cm³ | |

| DIN EN ISO 527 | 48 | MPa | |

| DIN EN ISO 527 | 1,700 | MPa | |

| DIN EN ISO 178 | 58 | MPa | |

| DIN EN ISO 178 | 1,500 | MPa | |

| DIN EN ISO 180 (Notched, Izod) | 4.4 | kJ/m² | |

| DIN EN ISO 527 | 15 | % | |

| DIN EN ISO 868 | 75 | Shore D | |

| ASTM D648 (@1.81 MPa) | 70 | °C | |

| ASTM D648 (@0.45 MPa) | 154 | °C | |

| DIN EN ISO 306 (10N) | 181 | °C | |

| DIN EN ISO 11357 (20°C/min) | 176 | °C |

Actual values may vary with build conditions and in relation to the part’s geometry and orientation.

Please get in touch with our team for more information and guidance.

Finishing degrees

The right finish can transform your print into a product. Explore the post-production finishes we offer for this material. If you have any questions or special requests, get in touch with us.

Train and learn

Get more from your next project with helpful resources dedicated to PA 12 Medical-Grade (PA 2201) and selective laser sintering.