CASE STUDY

To DARE Is to Do: How Metal 3D Printing Helps Cool DARE’s First Liquid-Fueled Rocket Engine

How do you cool an engine that burns at over 2000 degrees Celsius? That was just one of the challenges facing a group of students at TU Delft in Project Sparrow. We sat down with DARE members Jonathan Neeser and Willem Dekeyser to discuss how they found a solution through metal 3D printing with Materialise.

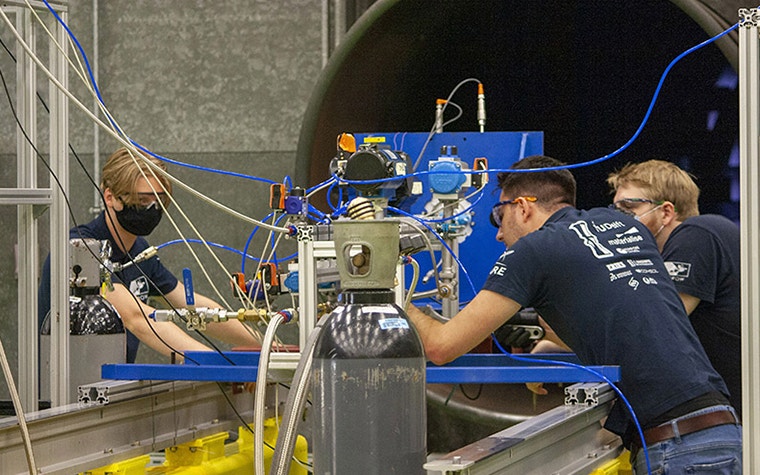

Since 2001, Delft Aerospace Rocket Engineering (DARE) has brought together students at the Netherland’s TU Delft, providing hands-on experience in different fields of rocketry with the aim of reaching space. Today, almost 200 members take part or have passed through, and they’re recognized as one of the most advanced student rocketry teams in the world.

To date, DARE has made over 160 successful launches and has taken part in the European Rocketry Challenge (EuRoc) in Portugal but has yet to reach its ultimate goal of passing the von Karmen line. However, through Project Sparrow, the team’s most recent endeavor, they hope to move one step closer with their first attempt at building a cryogenic liquid-fueled rocket engine, affectionately dubbed the Firebolt.

Challenge

“In DARE so far, we have mostly focused on developing solid and, especially, large hybrid rocket engines,” explains Jonathan Neeser, a master’s student in aerospace engineering and current member of DARE.

“For rockets in general, this has a couple of major advantages over, say, solid or hybrid propellants. Typically, it allows for very long burn times and high performance, but of course, it comes with a lot of challenges in terms of rocket and engine designing, particularly linked to cooling problems.”

Dealing with the issue of cooling soon became a priority for the team. Naturally, when working with volatile materials such as liquid oxygen, overheating can quickly lead to disaster — and it’s safe to say that when DARE’s Firebolt gets running, it’s going to run hot. With combustion gases reaching temperatures of up to 3000° Kelvin (2786° C), the combustion chamber walls need to be able to stand strong in the face of a pretty hostile environment.

“Our little engine has a higher energy output in terms of heat than the small nuclear research reactor we have here in Delft. Then you consider that the throat of our engine is just 5 cm in diameter. So, it’s very small and has a lot of energy, and that, of course, all needs to be dealt with.”

Willem Dekeyser, a master’s student in power propulsion at TU Delft who spent a year as a full-time combustion chamber and cooling engineer at Project Sparrow last year, helps put that challenge into perspective.

“A nice analogy is that our little engine has a higher energy output in terms of heat than the small nuclear research reactor we have here in Delft. Then you consider that the throat of our engine is just 5 cm in diameter. So, it’s very small and has a lot of energy, and that, of course, all needs to be dealt with.”

This challenge was identified as a key driver behind the engine’s design, with clearly identifiable requirements. The team would need to find a way to cool the engine using parts that could withstand such high temperatures themselves, could be produced with limited resources, and designed based mostly on theory with no opportunity to test the part in isolation.

Solution

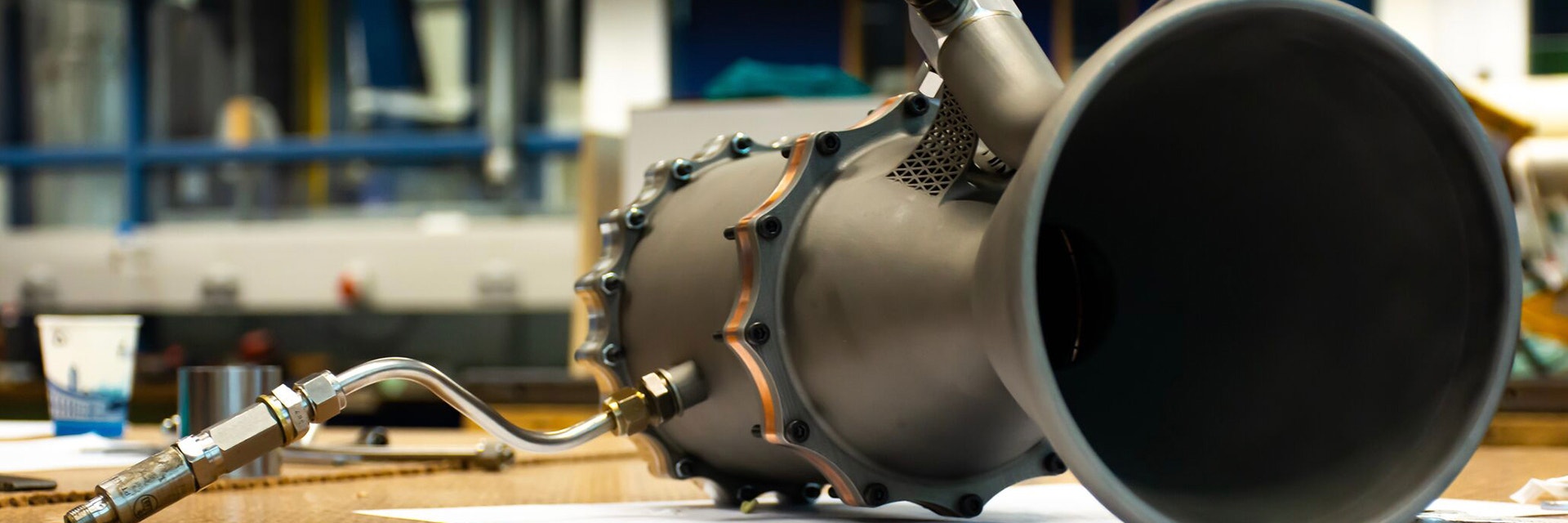

The solution, DARE decided, was to regeneratively cool the engine by passing ethanol through cooling channels built into an interior wall before entering into the combustion chamber itself. It begins with the volute, a cube-like part that sits at the bottom manifold of the engine’s nozzle, made from Inconel 718.

“You need to make sure that your wall remains below the material’s operating temperature, so of course, high-temperature materials such as titanium and Inconel are generally a relatively good choice. But with thermal stresses especially driving design criteria, Inconel became more and more attractive for us,” says Jonathan.

The next question was how to make it. Traditionally, metal parts would be created through milling or casting. However, with the walls fingernail-thin in some areas, the team felt these methods would not be up to scratch. Instead, they decided on metal 3D printing and turned to Materialise to design the part and bring it to life at the Metal Competence Center in Bremen.

“Materialise is one of the few companies that have experience working with Inconel, so it was logical to go to them. They mainly helped by designing the volute’s printing supports, setting up the prints, printing the part, and giving us feedback on what to change so it could be printed affordably.”

One of the primary goals of the Materialise Design and Engineering team was to design support structures for the volute in such a way that it could be printed without having to remove them afterward. They also helped prepare the file for post-machining in alignment with the team from Van Gompel, a Materialise partner. Within a few days of finalizing the design, the volute was ready and available for use in the first test of the Firebolt engine.

Result

“The contact with Materialise went really smoothly. For a lot of us, it was the first time designing for metal 3D printing. And while we have had some experience in working with this, I was quite pleasantly surprised that the part turned out as well as it did for the first try,” says Jonathan.

“Generally, when you try to make designs like this, it's very different from designing conventional parts, and actually having a result that is within spec and that turned out as well as it did was quite surprising to me.”

Designing future iterations is also sure to be even easier, with the benefit of experience from the first print and access to a program specially developed by Materialise to prepare any subsequent parts. As for the performance of the volute itself, Jonathan and Willem are as excited as anyone to find out for sure —unfortunately, the first test of the complete engine resulted in a bit of a bang.

“We actually had a detonation in our injector manifold, likely due to a faulty seal or sealing interface design. What was quite impressive was that the Inconel part itself survived remarkably well. Hardly a scratch on the thing — it's a very interesting alloy to work with for sure,” he adds.

While this event was always considered likely, it has put further tests on hold for a while, pending an investigation into what went wrong and any design changes the team decides to make as a result. In the meantime, neither Jonathan nor Willem expect to move away from Inconel or metal 3D printing for the volute, though some minor changes are likely.

“So, the inner wall of the combustion chamber that transfers the heat into our coolant is only about as thick as your fingernail and kind of straddles the porosity limits of Inconel metal 3D printing. With just half a millimeter thickness, it's only designed to carry thermal loads, with the pressure loads being relatively small.

“However, we noticed our igniter was so powerful and released so much heat that it actually burned a small hole into those very thin cooling channels. So, for example, that could result in some changes to the design, making that wall a little bit thicker, or reinforcing that area a little bit, or changing the ignition system.”

Like all projects that rely on trial and error, the team also found positives to the new design compared to previous efforts.

“Our battleship engine was a bit different than the Inconel one. It was a steel tube with a graphite nozzle insert. But we could fire it for no more than two seconds because otherwise, the chamber would just melt away. We expect that our new engine can burn for 40 seconds, which is already quite significant, really due to the combination of the cooling and the material itself,” explains Willem.

What next for Project Sparrow?

So, what comes next for this team of students? Will the Firebolt soon be blasting off again, or is space just one step too far? For now, Willem and Jonathan are keen to emphasize that for DARE, reaching that ultimate goal is a marathon, not a sprint. There are a lot of steps still to take before they set eyes on a fully functional engine, let alone a rocket that it carries into orbit.

However, talks between Materialise and the DARE team have recently begun, laying plans to design and print a second iteration of the design. It’s a project we’re excited to follow closely over the coming months and years.

Share on:

This case study in a few words

Aerospace

Optimize and 3D print a volute in Inconel 718 at Materialise’s Metal Competence Center

Cool a rocket engine combustion chamber reaching temperatures of up to 3000 Kelvin