CASE STUDY

Suction Gripper in 3D-Printed Aluminum: The Power of (Re)Design

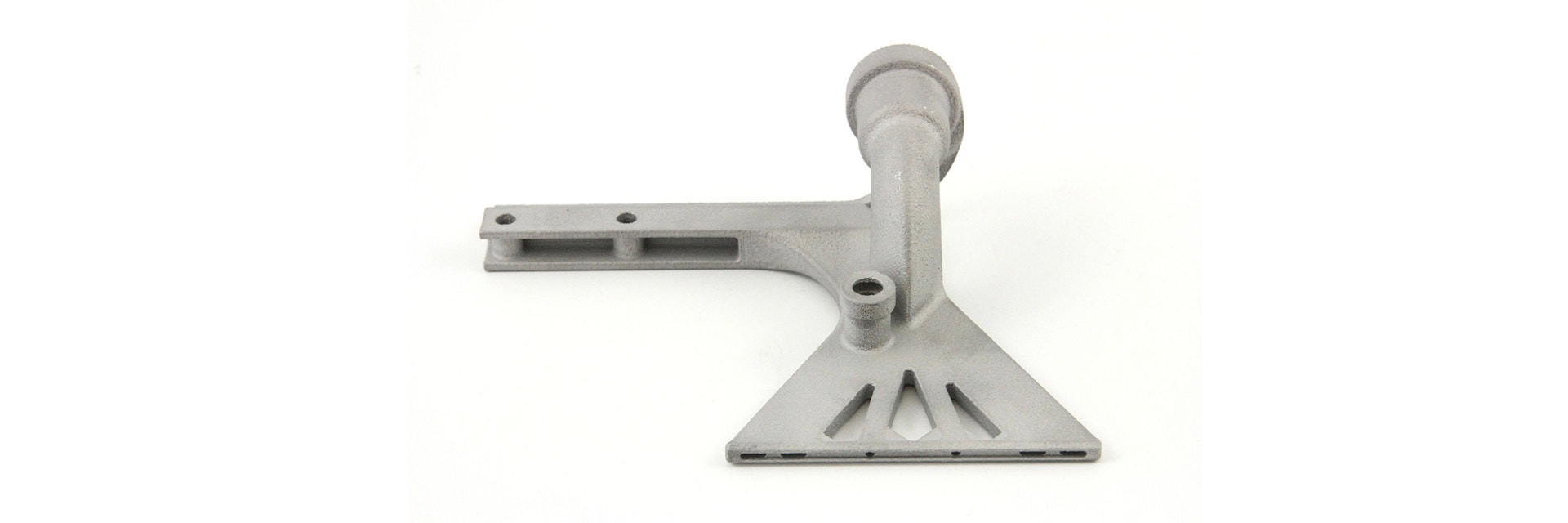

Making the most of additive manufacturing means taking a new approach to design. For this suction gripper, our Design & Engineering team evolved the design until we had a 3D-printed part that costs less than one-third of the original, is nearly a quarter of the weight, and needs no assembly.

The challenge

Minimize the cost, weight, and assembly of a suction gripper

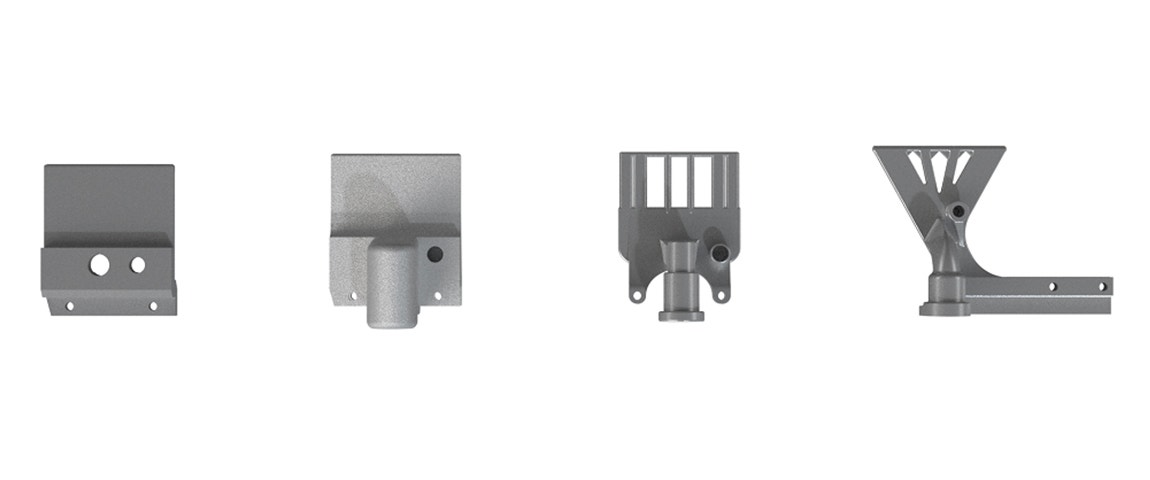

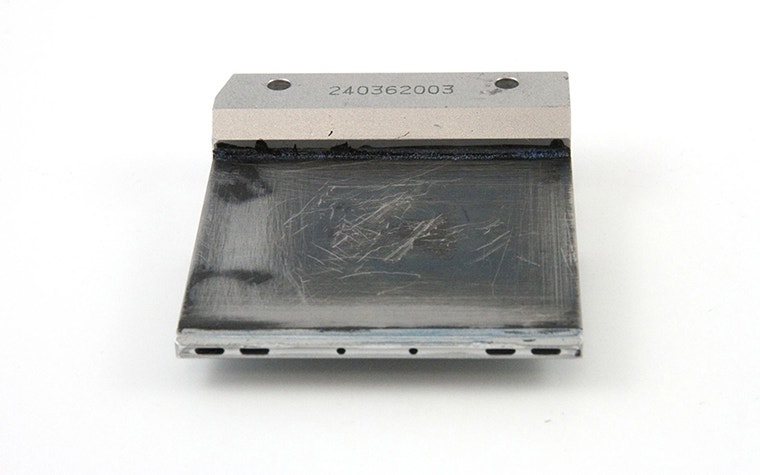

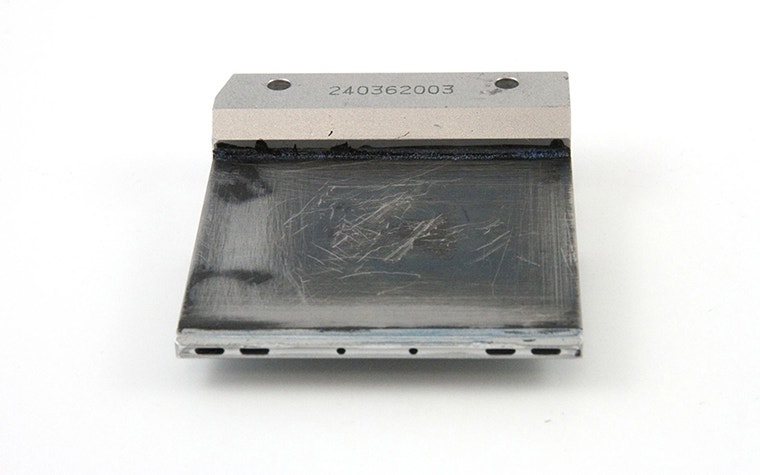

The above picture shows a suction gripper with internal air channels visible in the front plate, with interior air channels visible in the front plate. When this project arrived at the Materialise engineering team’s desk, the customer had already partially optimized the part for 3D printing. While the original part had been produced through milling followed by machining — a long, labor-intensive process — this design was intended for 3D printing in aluminum. A steel plate, tube, and connection arm would then be assembled manually.

The problem? The design was expensive, owing to heavy material usage and a need for manual assembly. After reviewing the design, our Design & Engineering team had a main goal of cost reduction. A secondary goal was to improve the gripper’s lifetime, as the customer’s experience showed that incorrect positioning of the part caused incremental damage over time.

The solution

Metal 3D printing with an optimized design

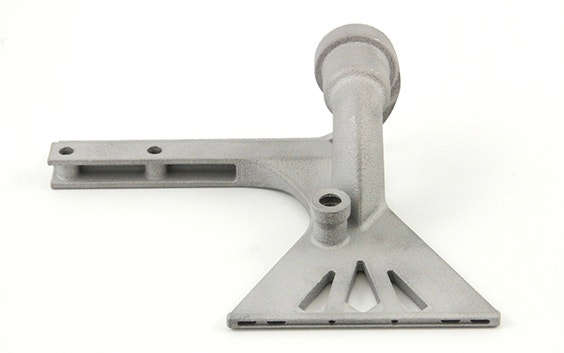

At Materialise, we believe that design optimization is a constant and crucial process. It’s particularly important when a part goes from traditional manufacturing techniques to 3D printing, where the same restrictions simply do not apply. In this case, our Design & Engineering team took the design through multiple stages of evolution until we achieved the goals. All while using the same material: aluminum.

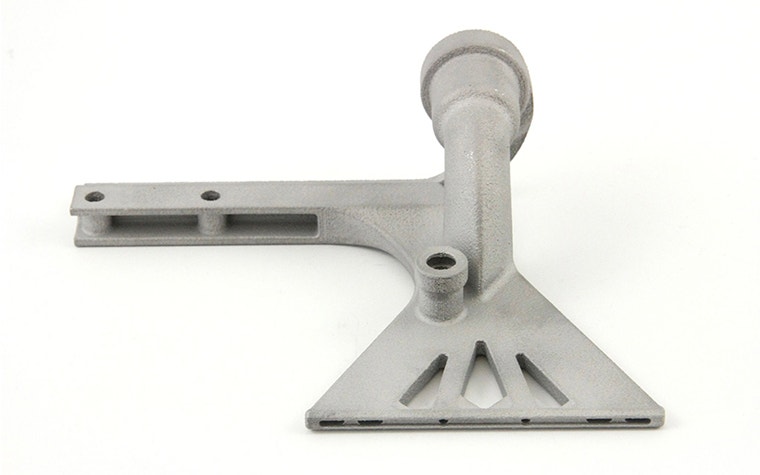

In additive manufacturing, generally speaking, design complexity is not a contributor to cost. Volume is, due to the associated material usage. So Materialise engineers first took the opportunity to replace the solid space of the gripper with a leaner version, requiring drastically less material. To reduce the amount of manual assembly required, the team integrated a connection tube within the gripper design. Integrated tubes not only reduce costs but also remove the risk of leakage.

But the part could still be made lighter and cheaper. Besides volume, another major cost driver in metal 3D printing is the support structure. Any unsupported overhangs could potentially deform during or after printing, owing to the high temperatures that the part is subjected to in the 3D printer — but supports the use of valuable material and raise costs.

The result

A lighter, more affordable gripper

Over the next two design iterations, Materialise engineers landed upon a funnel-shaped design and a build-platform orientation that drastically reduced the support structures needed, resulting in an aluminum suction gripper that is only 60g, as opposed to the original 237g.

And that 60g includes a new connection arm, integrated into the single-build design, which removes the need for manual assembly. Even better, it ensures the correct positioning of the part by removing the possibility of human error, thereby helping to increase the gripper’s lifetime.

“With the volume reduction and the integrated functionality, we’ve managed to cut down the cost by 70% with no assembly required,” explains Mathieu Cornelis, Account Manager at Materialise. “With thoughtful design and engineering, we were able to offer the customer a suction gripper that’s more performant and faster to manufacture at a far lower price.”

Share on:

This case study in a few words

Manufacturing

Metal 3D printing

Aluminum

Weight reduction

Cost reduction