EXPERT INSIGHT

3D Printing Smart Eyewear’s Must-Have Trinity: Fashion, Function, and Fit

Jan-Willem Billiet, Head of Smart Eyewear at Materialise, is here to explain why smart eyewear manufacturers can’t afford to ignore the three big Fs — and how adopting 3D printing is the key to delivering them all at once. Add in the economic benefits, and it’s clear why it’s the smart choice for smart eyewear.

Fashion, Function, and Fit. We call them smart eyewear’s must-have trinity, and that’s for good reason: if designers and manufacturers want their frame to be a success, it needs to deliver on all three. No exceptions. In this article, I’ll tell you more about what they mean, why they matter, and how to master them.

But first, some good news: it’s easier to achieve than you may think. With the right design and the right 3D printing partner, you’ll hit the mark on all three at once and enjoy some healthy economic benefits to boot.

F is for Fashion

Looking past their purpose and the things that make them tick, smart frames are, first and foremost, eyewear. Think of the Clark Kent effect — when someone puts on a pair of glasses, those frames become part of their identity. They must look good, even when the battery is dead. And it’s important that your consumers have choice — after all, Fashion is subjective.

When we worked on Morrow’s autofocal frames, choice was everything. They realized that there was no one-size-fits-all and wanted to offer styles that appealed to different tastes. Today, their offering includes more than 150 unique SKUs, ranging from size to shape and color.

“We now have more than 168 different frames on our website, available for people to try on. This was only possible through the flexibility of 3D printing.”

— Paul Marchal, Morrow Eyewear

That’s only possible — or, at least, financially feasible — because of 3D printing. Its unmatched design freedom lets creativity and innovation run wild. Sizes, shapes, and a choice between versatile polymers like PA 12 and highly appealing metals like titanium leave lots of room for imagination.

However, perhaps the most important thing is how 3D printing facilitates design iteration compared to technologies like injection molding. Designers can quickly amend their digital files to experiment with new designs rather than construct a new mold each time, then print them in limited runs to evaluate the market response, narrowing down exactly what their consumers want.

F is for Function

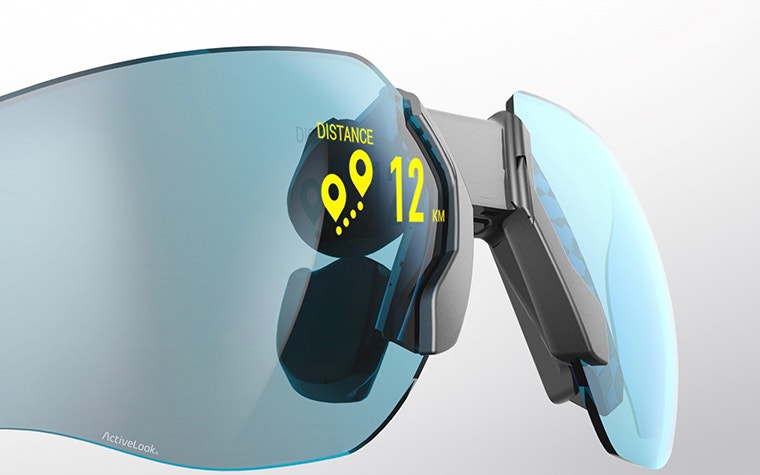

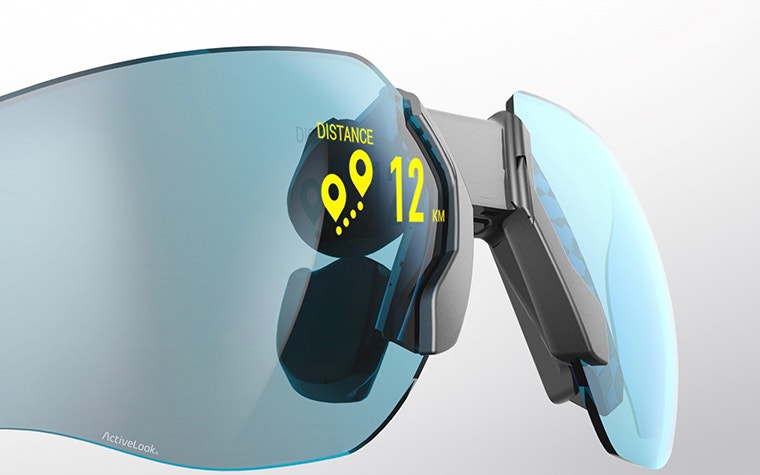

Whatever your smart frame does and whoever it’s for, it needs to work as intended. For that to happen, there’s a lot to carefully consider and test. Miniaturized electronics need to fit inside an eyewear form factor, and lens positioning is crucial. If anything is slightly out of place or moves over time, it can ruin the entire display or cause discomfort for the wearer.

3D printing delivers here, too — it allows designers to place the lens and its display at the center of their design, ensuring optimal positioning. Hiding the electronics is no issue, either. You can easily create complex structures within your frames, like hinge cavities for flex PCBs or internal channels for cables and wires — something near impossible with injection molding.

How designers take advantage of 3D printing's ability to integrate that complexity is up to them, and seeing the different solutions is really quite interesting. When Vuzix turned to 3D-printed titanium for the bridge of their Shield line, they ensured it both looked fantastic (Fashion) and resisted any torque to keep their waveguide-based displays functioning perfectly. Morrow’s frame connects its electronics to its lenses via a flex PCB nested in a cavity at the top of the frame, while Engo seats theirs around the nose piece of their sporty glasses.

Once again, there’s plenty of room for creativity.

“Firstly, they did a great job helping us get the rigidity we needed from a printed device. Then there’s the finishing work they did on that printed device. Quite frankly, it’s a beautiful piece of technology.”

— Shane Porzio, Vuzix

F is for Fit

Last but not least, we come to Fit. The two primary considerations for designers here are comfort and performance. It begins with simple wearability — your customers should be able to wear their frames all day without discomfort or having their glasses wobble or slip around on their faces.

Preventing that movement is also integral to performance. I mentioned earlier that 3D printing allows designers to center their design around the lens and take full control of lens positioning, and that’s the main focus here, too. If the eye box is never where you intended it to be because of a poor Fit, smart eyewear won’t Function either.

A poor fit is a major factor in frames not being used, or worse, being returned. By offering a range of sizes — as simple as small, medium, and large — you’re much more likely to ensure an optimal performance for as much of the population as possible.

3D printing delivers here, too. Its accuracy ensures the correct lens positioning with every print, while an absence of tooling costs allows designers to produce these options in an agile and cost-effective way. It effectively facilitates mass customization to varying degrees.

“Today, personalization is a huge trend in many industries. There is a very strong emerging demand for this. Being able to offer made-to-measure frames responds to this demand: choose your shape, choose your color, choose your size. It’s a real innovation and an undeniable plus for our guests.”

— Frederic Beausoleil, Acuitis

Don’t forget the economic benefits

Like any other application, the decision to adopt 3D printing should be based on a strong business case, meaning it makes sense financially. And in 99% of smart eyewear cases, it will. Let’s break down a few of the key economic benefits the technology offers:

No tooling costs

3D printing vs injection molding is likely to be one of the first topics you tackle when considering series production for your frames. For volumes up to 20,000 per SKU, 3D printing is the better option — and that’s before you even consider the advantages it has for design updates. Working with digital files rather than molds makes it much easier to make changes, also mitigating the obsolescence and miniaturization of your electronic parts.

“There’s a lot of iteration that has to happen. You make a cut, find something that doesn’t work or you don’t like, so you make another cut, then another — if you were doing that with injection molded parts, it would be incredibly expensive and time-consuming because of the tooling changes and the like. With 3D printing at Materialise, our iterative design process allows for lightning-fast prototyping.”

— Shane Porzio, Vuzix

Fast time-to-market

The early bird gets the worm — so you want to get there fast. With 3D printing, you can go through all the prototyping phases and get your collection launched in as little as three months, whereas you’re looking at anywhere between 12 – 18 months with injection molding.

Customization

As I touched on briefly when discussing why the Fit of your frames is so important, by ensuring comfort and optimal performance for as much of the population as possible, you’ll both serve a larger part of the population and limit the number of frames sent back.

Tools like the Materialise Fitting Suite are an incredible help here. This state-of-the-art fitting tool facilitates mass customization by ensuring a perfect fit — and optimal viewing performance — for every wearer. Combining a patent-pending population-based algorithm with a mirror-realistic video experience, each customer will receive a frame that fits them perfectly and matches their taste. By measuring centration values like PD, fitting height, pantoscopic tilt, and eye point relief, we can guarantee optimal eye box alignment for any type of display and design.

Materialise — your 3D printing partner for smart eyewear

If you’ve made it this far, you now know why 3D printing is the smart choice for smart eyewear. But you may have a few questions surrounding how to use it. The first step to answering that is finding a good 3D printing partner — and I’m not afraid to say that it’s hard to do better than Materialise.

Whether you need advice on designing for additive manufacturing, want the security of printing in our eyewear-certified manufacturing facility with a capacity of over 1 million frames per year, or anything else, we’re well-placed to bring your collection from concept to completion — must-have trinity included.

Header image: ©Vuzix

Share on:

Meet the author

Jan-Willem Billiet

You might also like

Never miss a story like this. Get curated content delivered straight to your inbox.