Medtech

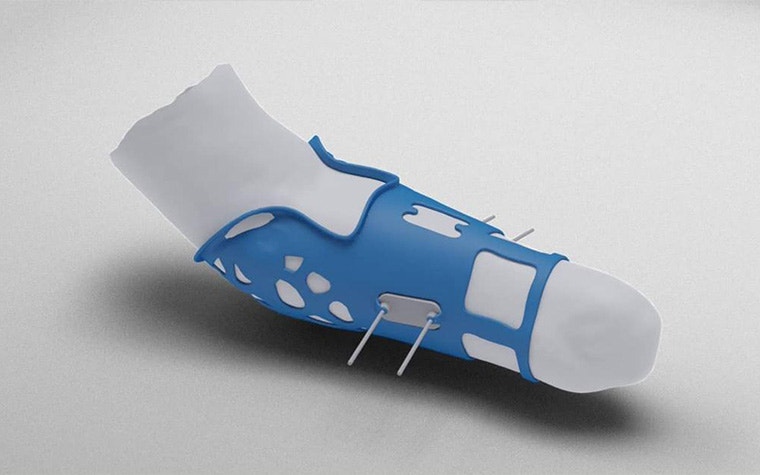

Orthotics and Prosthetics

Every patient is unique. Your products should be, too.

Orthotics and prosthetics are ideal applications for 3D printing, bringing many advantages to both patients and professionals. Discover how you can take advantage of them all, from improving treatment plans through personalized devices to the added efficiency of design automation and simplified workflows.

Why choose 3D printing?

Simplified design-to-order workflow

Whether it’s moving from design to (re)order at the click of a button in footscan or taking advantage of in-house post-processing services, creating a finished part is faster and more efficient with AM.

No minimum order quantities

With no minimum order quantities, manufacturing with 3D printing can start at a series of one. Produce unique components on demand and eliminate the need for tooling or build high-quality masters for vacuum casting.

Why choose Materialise?

Ideal materials

PA 12 Medical-Grade (PA 2201)

Technology

Selective laser sintering

Description

PA 12 Medical-Grade offers high strength, chemical resistance, and detail resolution, making it ideal for high-quality and fully-functional biocompatible plastic parts for settings such as operating rooms. This material is subjected to testing for cytotoxicity, sensitization, irritation, acute systemic toxicity, and material-mediated pyrogenicity.

Key characteristics

- Biocompatible material

- High strength and stiffness

- Good chemical resistance

- High selectivity and detail resolution

- Max part dimensions: 170 x 215 x 320 mm

PA 11

Technology

Multi Jet Fusion

Description

Combining excellent mechanical properties with impressive surface quality and detail, this material is ideal for both series production and functional prototypes, especially in industries like medtech (O&P), aerospace, and automotive.

Key characteristics

- Flexible and stress-resistant

- Excellent surface detail and dimensional accuracy

- High density and isotropy

- Smooth surface quality with minimal post-processing

- Max part dimensions: 370 x 274 x 375 mm

PA 2210 FR

Technology

Selective laser sintering

Description

PA 2210 FR is a high-performance, UL Blue Card-certified polyamide containing a halogen-free flame retardant. Excellent long-term stability and good chemical resistance make it ideal for functional prototypes or end-use parts.

Key characteristics

- Strong material printed without a support structure

- Flame retardant — UL Blue Card-certified (UL 94 rating of V-0 at 3 mm wall thickness), CS/FAR 25.853 compliant

- High chemical, mechanical, and thermal resistance

- Max part dimensions: 280 x 280 x 550 mm

ABS-like Polyurethanes

Technology

Vacuum casting

Description

Offering a range of different material properties, our ABS-like polyurethanes can be used with silicone molds to produce high-quality prototypes or small series of end-use parts.

Key characteristics

- Excellent surface and detail, with injection-molded look and feel

- Flame-retardant, food-safe, and UV-stable materials available

- Cost-effective way to produce prototypes or small series of end-use parts

- Max part dimensions: 1,900 x 900 x 750 mm (maximum part volume: 10 liters)

Stainless Steel (SS316L)

Technology

Metal 3D printing

Description

Stainless steel (SS316L) is a low-carbon stainless steel alloy that offers excellent strength, high corrosion resistance and ductility, and good thermal properties.

Key characteristics

- Excellent strength

- High corrosion, temperature, and chemical resistance

- High ductility

- Suitable for food-safe applications

- Max part dimensions: 250 x 250 x 305 mm

Titanium (Ti₆Al₄V)

Technology

Metal 3D printing

Description

Ti₆Al₄V is a lightweight titanium alloy with excellent mechanical strength and superior corrosion resistance, making it ideal for high-performance end-use parts.

Key characteristics

- Excellent mechanical properties

- Lightweight, with a high strength-to-weight ratio

- High corrosion and temperature resistance

- Suitable for post-machining

- Max part dimensions: 250 x 250 x 305 mm

Ultrasint TPU 90A-01

Technology

Multi Jet Fusion

Description

Ultrasint TPU 90A-01 combines durable elasticity with good wear and abrasion resistance, making it ideal for prototypes and end-use applications that require good shock absorption.

Key characteristics

- Rubber-like material printed without a support structure

- Durable elasticity with high elongation at break

- Good wear and abrasion resistance, and good shock absorption

- Max part dimensions: 370 x 274 x 375 mm

Polypropylene (PP)

Technology

Selective laser sintering

Description

A tough, fatigue-resistant, and lightweight material, polypropylene (PP) is ideal for functional prototypes of snap-fit assemblies or living hinges in automotive components, packaging, and consumer goods.

Key characteristics

- Tough yet flexible material printed without a support structure

- Very high elongation at break (> 500%)

- Lightweight and fatigue resistant

- Max part dimensions: 480 x 480 x 430 mm

Typical applications

Prosthetic limbs and liners

Whether turning to 3D printing for its speed and freedom of design or relying on software to automate the design process and reduce the risk of errors, like in the case of Heygears, the technology is a proven game-changer for prosthetic limbs.

Rehabilitation aids

Mobility aids outside of prosthetics and orthotics, such as wheelchairs and exoskeletons, also benefit from 3D printing. Whether through lightweighting, personalization, or enabling scalability, it helps improve results for patients and manufacturers alike.

Our products and services

Ready to start your project with us? Discover our solutions, ideal for medtech.

Innovate and speed up your manufacturing in collaboration with our experts. Rely on our full range of in-house technologies suitable for all industries and applications.

Transform your product development cycle and get the best possible products to market faster. Get unbiased advice and dedicated support from teams committed to your success.

Get direct 24/7 access to the technologies and materials you need to bring your designs to life. Instant quotes, short lead-times, and easy checkout.

Build your success on a platform of software tools that efficiently manage and control the 3D printing process, allowing you to meet the highest standards of the most demanding industries.

From bespoke surgical knee guides to true-to-life 3D-printed models of the human heart, our medical software and printing facilities are helping to bring personalized healthcare to everyone.

Discover the precise and seamless digital workflow designed by foot and ankle experts for foot and ankle experts based on scientific research

Connect and streamline your AM workflows to the production floor with business systems, machine connectivity, and solutions that improve quality output and ROI.

Inspiration

Get inspired for your next project with a look at how others have used 3D printing for medtech.