EXPERT INSIGHT

30 Years of Innovation: Bringing 3D Printing’s Benefits to Metal

Part of the Materialise portfolio since the mid-2010s, metal 3D printing combines the advantages of additive manufacturing with tried-and-tested materials like titanium and stainless steel. Discover how our Metal Competence Center in Bremen, Germany is working to further develop the technology.

In 2020, we celebrated Materialise’s 30th anniversary. Our 30 Years of Innovation blog series highlights some of the different 3D printing technologies that have helped our customers achieve their ambitions over the years and shows that there is no one-size-fits-all approach to 3D printing. This time, it’s the turn of metal 3D printing.

3D printing for plastics was the blueprint for additive manufacturing (AM) innovators to create metal 3D printing processes. Once the laser sintering technology was patented, users began to experiment with applying the process to various metals as well. After a significant industry-wide research phase to improve the technology over the years, it became a reliable, high-quality option by the mid-2010s.

At this point, Materialise brought metal AM into our manufacturing portfolio to not only provide the printing service to our customers but to also use our AM expertise to further improve the technology.

“We offer a service that assists customers during each step of Metal 3D printing. Our teams are all extremely knowledgeable about how best to use the technology and ensure that our customers get the most out of it. ”

— Ingo Uckelmann, Technical Manager of metal 3D printing, Materialise

The appeal of metal 3D printing was clear. Just like for plastics, companies had the opportunity to receive parts faster than ever before, but now with such robust materials. 3D printing doesn’t require the time-consuming creation of molds or production lines like traditional technologies — with a digital file in hand, almost any design can be printed within approximately ten working days. However, we recognized that, more often than not, the orders we received didn’t benefit from all of the technology’s advantages. With our know-how and design expertise, there was untapped potential that we could help our customers reach — design freedom, cost reductions, and risk mitigation, for example.

So, with metal 3D printing in our portfolio, we placed a focus on helping our customers leverage all of its benefits. And today, we continue to innovate to drive the technology and our metal services forward. Our team is working to see that metal 3D printing is not just a quicker alternative to manufacturing metals, but the preferred method.

The one-stop-shop for metal 3D printing

To become true specialists in metal AM, we decided to expand our services into a location where we could both meet the demands of our orders and be near our customers and other leaders in the manufacturing world. That is why we opened a facility dedicated to metal 3D printing in Bremen, Germany, in 2015. In this way, we could continuously learn about industries such as aerospace, automotive, industrial automation, and eyewear to advance our services.

Once the facility was in place, we could provide a service that assisted customers in using metal AM to its full potential throughout the entire production process, from design to finish.

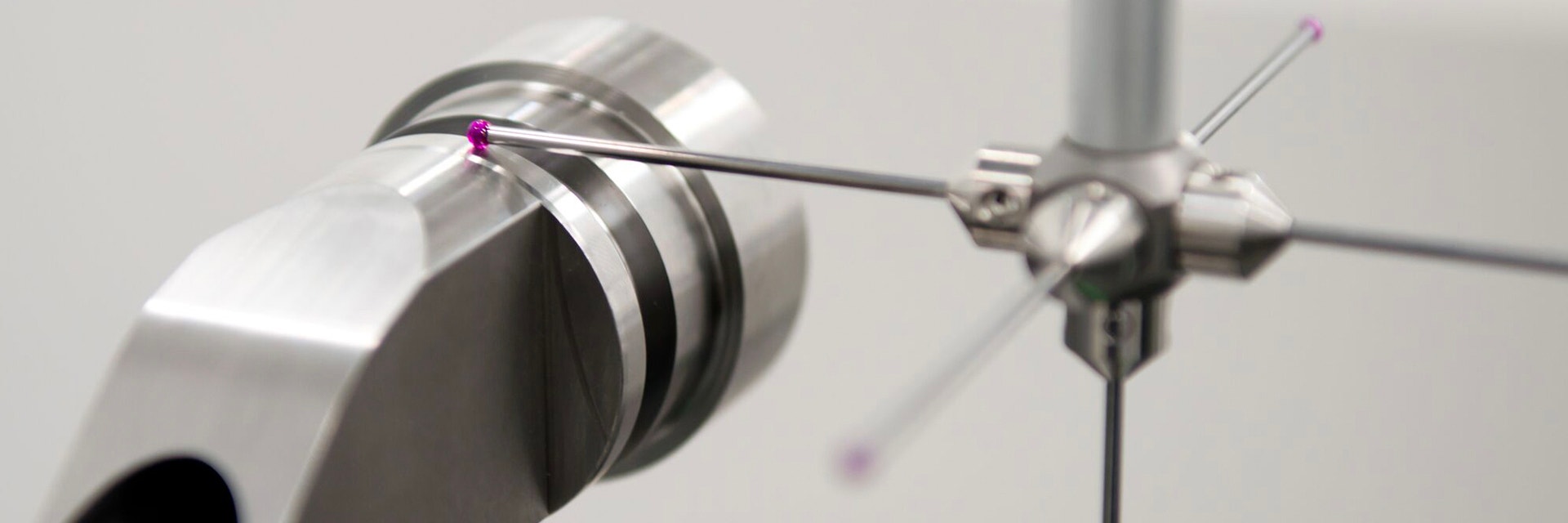

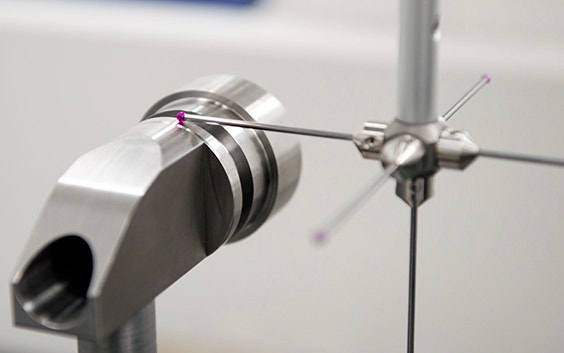

“We offer a service that assists customers during each step of Metal 3D printing,” shares Ingo Uckelmann, Technical Manager of Metal 3D Printing. “Our design and engineering, certified manufacturing, and post-machining teams are all extremely knowledgeable about how best to use the technology and ensure that our customers get the most out of it.”

Let’s demonstrate this idea with our design and engineering team’s work on optimizing the design of a metal suction gripper. The team worked closely with the customer to completely redesign their production part using design for AM principles. Because of these changes, the brand-new part was 94% lighter, 50% cheaper, and more performant.

The team also began initiatives to improve the quality and consistency of the technology — a mission that continues to remain a focus. To do so, the team began by ensuring consistent alloys via internal testing and aligning our alloy standards to those of our proven plastics offerings.

“We’re developing the technologies of tomorrow.”

— Ingo Uckelmann, Technical Manager of Metal 3D Printing, Materialise

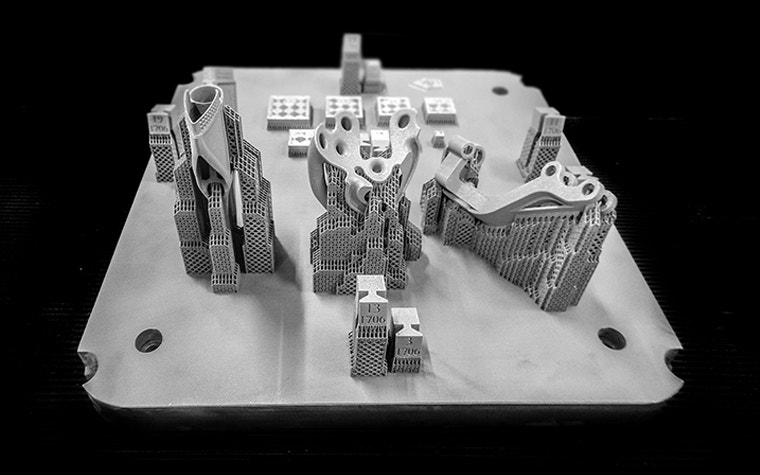

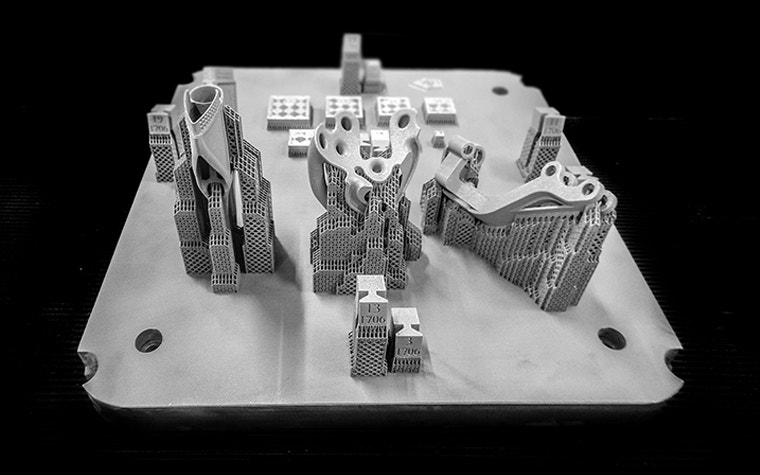

One of the projects our Bremen facility achieved to enhance metal AM was the distinction between Standard and Performance metals. We split our existing alloys — aluminum, titanium, stainless steel, and Inconel — into these two categories so our customers better know what to expect from our materials.

The Standard option is what customers would expect from a metal — it is a well-rounded grade that holds the same qualities as metals used in other manufacturing methods. As for the Performance grade, this is for users who are well-versed in metal 3D printing. It’s ideal for projects where a design is made for metal 3D printing specifically, to create organic shapes that can’t be achieved with traditional manufacturing, or for series productions of end-use parts, for example.

Taking metal AM to the next level

At Materialise, we’re constantly aiming higher to improve our technologies and make the advantages of 3D printing more accessible. This mission is no different with metal AM. We want every customer to experience lighter parts, cost-effectiveness, and freedom of design combined with the durability of metal materials. Then, metal 3D printing will surely be everyone’s first choice for manufacturing, not just the option they turn to when they need a quicker alternative. This is why we installed the new Metal Competence Center at our Bremen facilities in early 2021.

This center was created to bring together our experts in both AM software and production capabilities to advance metal 3D printing while supporting a sustainable future. Here, the team can face any economic or ecological challenge head-on and build solutions with metal 3D printing’s capabilities to overcome it. They uniquely combine expertise from the production floor with know-how from decades of AM software development to further increase the technology’s reliability and consistency.

Thanks to this collaboration, the Metal Competence Center production can be the first to work with the latest, most innovative software from our team, and the software developers can enhance the software with direct feedback from production. This rapid feedback and development cycle enables the team to quickly and continuously improve their services to bring the best to customers.

“At our Metal Competence Center in Bremen, we’re developing the technologies of tomorrow,” explains Ingo. “By improving metal AM to make it easier, more accessible, and more affordable, we will ensure that it’s a viable technology that companies will turn to first for their metal parts.”

As we’ve looked deeper into our own processes and fine-tuned metal AM software and workflows, we’ve effectively automated many tasks, thus shortening lead times and lowering costs. Enhancing the technology through automation and design for metal AM helps our customers reach the next level with their metal parts while keeping costs low. For series productions, we work alongside customers to enable customization and improved parts with the power of metal 3D printing — all while meeting their time, financial, and quality expectations.

以下で共有する:

こちらもご覧ください

このようなストーリーをお見逃しなく。 月に1度、メールで新しいコンテンツをご案内します。