CASE STUDY

GKN Aerospace’s Additively Manufactured Winglet: From Paper to Plane in Just 14 Months

Short deadlines and complex geometries are additive manufacturing’s bread and butter. Discover how GKN Aerospace used the technology to produce its all-important winglet — and open the eyes of an industry.

The challenge

Produce a complex flight-ready winglet in record time

Time was already tight when Eviation, an aerospace company dedicated to developing sustainable, all-electric solutions for air travel, approached GKN Aerospace to develop several key components for the Alice V2. The deadline to build a flight-ready model of this fully electric airplane was approaching fast. But aerospace is not an industry known for developing things quickly. Safety is always more important than speed.

GKN Aerospace’s challenge was to find a solution that combined the two when developing the parts assigned to them: the empennage, the electrical wiring interconnection systems, and the wings — their winglets, in particular.

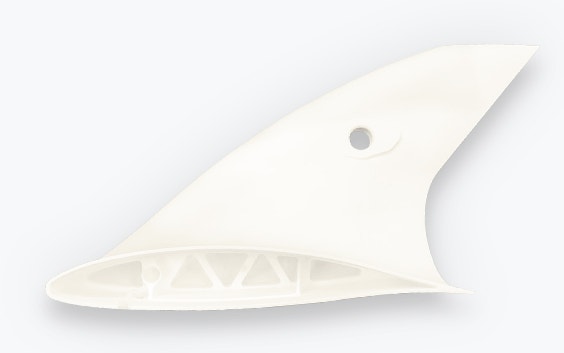

“We needed to produce an aircraft very quickly, and it also needed to hit certain weight targets,” recalls Russ Brigham, Program Director at GKN Aerospace. “The Alice V2 design has a winglet with quite a complex geometry and a navigation light interface. We spent a lot of time thinking about how we could produce that part because it is not insignificant in terms of the aircraft. It's a primary structural component. And we were up against it in terms of being able to deliver that with conventional manufacturing technologies.”

The solution

Certified manufacturing for aerospace at Materialise

A complex, lightweight part with a short lead time sounds like an ideal application for AM. But while the technology is now commonplace in the aerospace industry — typically for simple casings and other cosmetic items — it is not often that an aircraft features a primary structural additively manufactured component.

“When you’re right in the thick of a full-blown aircraft development program with a very tight timeframe, you need to make some bold decisions,” says Russ. “The bold decision was to go forward with the additively manufactured part and prove it was the right choice for a flight-ready component.”

While the decision was undoubtedly a brave one, it was not uninformed. Whether through partnerships with Fokker, now part of GKN Aerospace, or with GKN Aerospace themselves, Materialise has delivered on additive manufacturing projects with Russ’ team since before 2010. This has led to a certified process for use on aerospace parts made with selective laser sintering (SLS) and PA 12 — a combination that the team also turned to for the winglet.

“We had already done some testing with Materialise, particularly around mechanical allowables — the strength of the materials. But, of course, that strength is dependent on the geometry and the form of the components you need to manufacture,” explains Russ. “So you’ve got that basic data, but you’ve got to apply it specifically to the winglet.”

“As this was a new component, all we had was the outside external shape and the actual physical loads that you would see in flight. The Materialise team offered their input on the design in terms of manufacturability, and then we pressed ahead and made the parts.”

Testing to destruction

With the winglets delivered, Russ and his team had to move forward with stringent quality tests to meet the FAA’s demands for flightworthiness. After all, safety will always be paramount.

“We procured several winglets and undertook a destructive test program,” says Russ. “We took it to destruction, ultimately proving it was good for flight, and it worked.”

“As opportunities come along in the future, it (additive manufacturing) will be a candidate as opposed to dismissed, which is what it was before.”

The result

A lightweight, flight-ready winglet, delivered in just 14 months

On September 27, 2022, approximately 14 months after the project began, the Eviation Alice took its first flight — a process Russ says would normally take around five years. Almost one year later, it remains the largest fully electric airplane ever flown. Additive manufacturing's role in this achievement cannot be understated.

“I’d have been late,” Russ replies simply when asked what would have happened without the technology. “But it will also be crucial when the program goes into serial production. Being able to quickly and cost-effectively produce a replacement will be very important because, normally, damaged winglets are incredibly expensive.

“You’ve got two options, and neither is attractive: either buy a new one or spend a lot of time and money repairing it. So, a technology like additive manufacturing with its speed and cost advantages is really quite an interesting proposition for damage-prone components.”

Looking forward

So, what comes next for the Eviation Alice Winglet?

“We're now at the early stages of talking about how we take the current designs of the development airplane forward to a certifiable product and go into serial production,” says Russ. “The big challenge now will be to make the part even lighter, finding that balance between weight and capability.”

For GKN Aerospace — and potentially the broader aerospace industry — the experience has helped open minds even further to the potential of 3D printing.

“What it’s done is prove internally and possibly externally that in the right applications, we can use additive manufacturing beyond basic, simple products,” explains Russ. “So, building on this experience, we're looking at other AM opportunities for more high-criticality parts in the right applications because the Alice showed us that we can go there physically.

“As opportunities come along in the future, it'll be a candidate as opposed to dismissed, which is what it was before.”

Share on:

This case study in a few words

Aerospace

- SLS

- PA 12

- Manufacturing services

- Certified manufacturing

- Speed

- Affordability

- Design flexibility

- Complex geometries