EXPERT INSIGHT

Want to Achieve a Sustainable Production Process? Start By Connecting Your Data via a Digital Thread

Sustainability is in the hearts and minds of every player in the consumer supply chain. And for companies adopting 3D printing for their production, building a coherent digital thread with the right software and expertise is paramount. Want to know how? Here are four ways to integrate data across every stage of your additive manufacturing (AM) process with actionable tips that will make a significant difference to your production and help you fulfill your sustainability ambitions.

1. Analyze, control, and reduce waste with AM software

3D printing has many advantages. One of these is its ability to move businesses toward digital inventories, which are a key component of on-demand manufacturing. This benefits companies in industries like automotive that rely on just-in-time delivery and eyewear, where brands can eliminate excess inventory, substantially reducing storage costs and surplus stock.

In the eyewear industry, an increasing number of brands are using 3D printing to control waste and pursue a more sustainable business model. Part of the broader fashion industry, accounting for around 10% of global CO2 emissions,1 the eyewear industry has faced challenges associated with the fast fashion model for a while.

First, quick-changing trends make it difficult for the industry to keep up with consumer demand. Second, launching new designs to the market can be risky due to the time and resources that eyewear companies must invest in the process. These two factors put eyewear brands at risk of overproducing units, leading to waste materials and companies making overall losses.

However, with 3D printing, up-and-coming eyewear brands are seeing a new way forward. For example, Odette Lunettes, a Belgian brand known for its unique frames, has been leveraging 3D printing to tackle consumer trends and waste. They’re using AM to accelerate their time-to-market for new designs, allowing them to keep up with rapidly changing trends while cutting back on overconsumption of material and resources through a made-to-order model.

The brand’s collection, Odette Lunettes X Tom Boonen, demonstrates this new, more sustainable model perfectly. The 3D-printed frames, made from bio-based Ultrasint PA11, are customized to the wearer and produced on demand, decreasing the risk of overproduction. They worked with us to bring their lightweight, durable, and fashionable eyewear to life — offering their customers what they’ve been craving from the fashion industry: sustainable multifunctional eyewear. It’s a journey that took only two months to develop and launch. How? Mainly based on AM’s capabilities and an optimized digital design process.

“Sustainability needs to be in every aspect of your brand,” says Eline De Munck, Founder of Odette Lunettes. “With 3D printing and PA11 together, we are really able to deliver on that commitment and produce frames that are both fashionable and sustainable.”

Along with sustainability, another characteristic that customers want is frames that fit. An empirical study of 4,500 adults in the UK and the US showed that retailers in these countries who choose not to offer a personalized experience contribute to $26 billion of lost revenue every year.2 And in retail, there’s a growing interest in customization. The study confirms that fit matters most — and yet, 1 in 4 adults in the UK and US leave stores disappointed and empty-handed with their needs being unmet.3

Yet, with the rise of a new wave of digital tools like the Eyewear Fitting Suite, customization in eyewear is accessible to a broader audience than ever, meeting the needs of retailers and customers. With this in-store platform, retailers can scan the customer’s face using a handheld device, create an anatomically exact 3D model, and then guide them through a selection process.

Together, they can adjust shapes, colors, sizes, and more, ultimately creating a unique frame (and a unique customer journey) that suits each buyer perfectly. By utilizing core assets like 3D printing’s design freedom, retailers can serve their users’ needs quickly, affordably, and in batches of one to further cut down on stock risk and waste.

As you can see, going digital offers more than just faster time-to-market and decreasing excess stock risk; it also has an impact on the products that you print and your supply chain in general. The modules in our Pre-Print and AM Digital Factory Software — Materialise Magics’ Ansys Simulation, Quality & Process Control’s (QPC) Layer Analysis, and the CO-AM Software Platform’s Shopfloor Telemetry — allow you to:

- Gain control over your material usage

- Cut waste by optimizing your AM designs

- Identify scrap and defects earlier

- Ensure efficient production planning

Along with these software solutions, our 3D printing manufacturing services offer different methods to recycle and reuse excess material to give new life to waste/excess powder. These initiatives helped us cut around 30 tonnes of waste in 2023.

2. Improve production efficiency with automation

Minimizing how much material you use and the amount of energy your 3D printers consume are other factors you should consider — and they can be easily managed via software automation tools.

Magics’ modules, such as e-Stage for Resin for stereolithography and Nester for selective laser sintering technologies, reduce human error and ensure first-time-right prints while lowering the chance of scrap or waste. These modules also help you optimize your printing processes and reduce your energy usage: two things you need to pay attention to, especially when energy prices are high.

Additionally, Shopfloor Telemetry is another automation tool that allows you to monitor and predict your 3D printer’s maintenance window, reducing unnecessary downtime and safeguarding optimal performance for your production.

3. Design AM parts with sustainability at the forefront

Working with design for additive manufacturing (DfAM) experts ensures you take full advantage of 3D printing’s design freedom. Why is this important? You can reduce weight and build more complex or functional features for your parts. This creates endless opportunities for you to produce components that can do amazing things: a process that’s inconceivable when using other manufacturing methods. This is all while directly contributing to your sustainability ambitions.

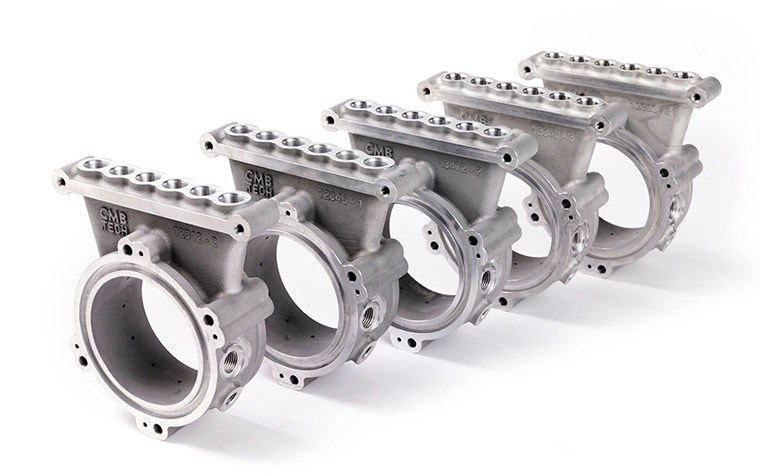

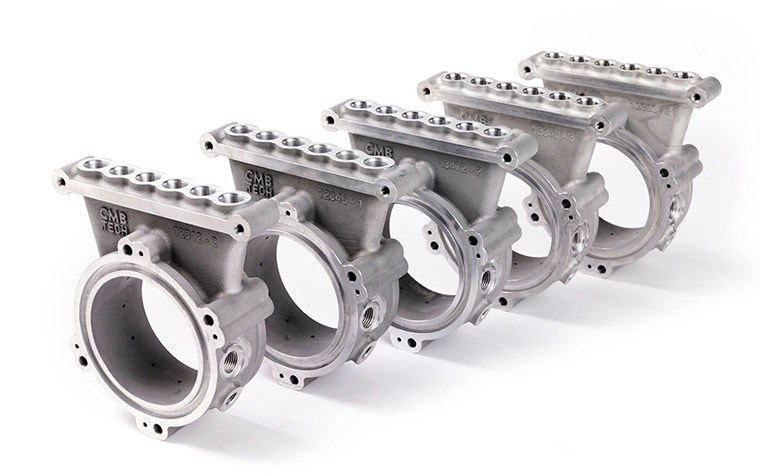

One company that unlocked AM’s potential to further its sustainability goals was CMB.Tech. They used metal 3D printing for a critical injection ring component when converting diesel engines to their dual-fuel (hydrogen-diesel) system.

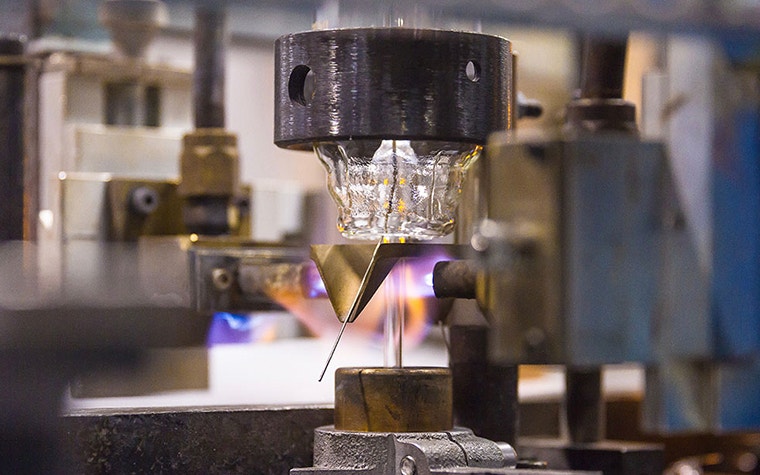

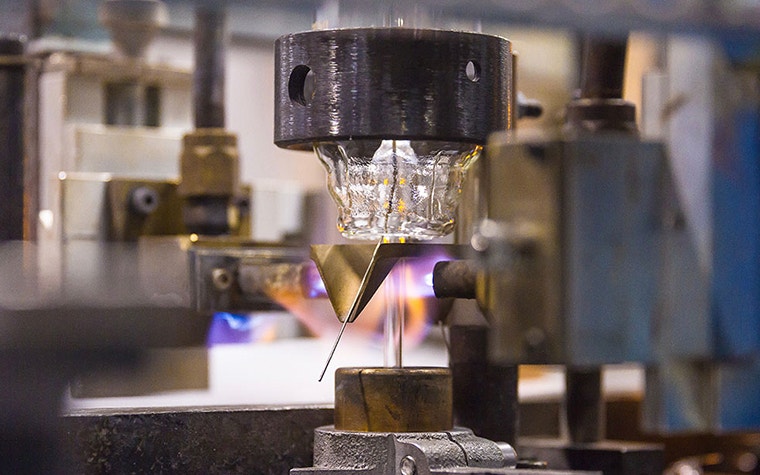

Consulting with experts will help you identify and spot potential new applications that could benefit from 3D printing and make a difference in your business. Signify, formerly Philips Lighting, achieved just that, fixing production tools that were prone to constant breakages. They managed to redesign a bracket-holder that was repeatedly failing to improve its performance. That resulted in other benefits such as boosting employee morale and giving their staff time to work on more valuable tasks.

4. Enable continuous improvement, empower staff innovation, and connect data via a digital thread using a unified AM platform

A digital thread enables more than just on-demand manufacturing and connected systems. It grants access to feedback that can feed continuous improvement. Connecting to a digital thread opens the possibility of receiving an abundant data supply. By seeing what works and what can be improved, you can foster a culture that drives continuous improvement and further iterations. This methodology is essential to propel your sustainability initiatives.

Data is the new oil,4 and the more data you have that can be analyzed effectively, the more efficient and sustainable your production processes can become. Data is an impactful tool, especially when it’s used to develop new materials and methods. And that’s what we can provide with our AM software solutions. CO-AM and the QPC system are tools our organization uses to facilitate greater efficiency, 3D printing reliability and repeatability, and internal communication.

They help us centralize different inputs — specifically build, process, and quality data — to streamline our decision-making and manufacturing processes so that our production teams can easily identify quality gaps, defects, and anomalies. You can also use these tools in your production workflows, turning your data stream into actionable insights and sustainable processes to keep your business thriving.

Can’t wait to start? Let us help you build a digital thread

We can advise you on how to do it, from finding the ideal AM software solution for your company to spotting the right applications that support your sustainability ambitions. Or if scaling to series production is your goal, we can do that, too. Whatever you need, you can count on our experts to guide you in the right direction.

1 World Bank Group: How Much Do Our Wardrobes Cost to the Environment?

2, 3 Thaw, G., 2019. Delivering a Fitted Experience in eyewear, A Research Study Into the Importance of Fit on Buyer Experience, s.l.: fitsyou.fuel3d.com.

4 Forbes: Data Is The New Oil -- And That's A Good Thing

Share on:

You might also like

Never miss a story like this. Get curated content delivered straight to your inbox.