CUSTOMER STORY

How 3D Printing’s Design Freedom Empowers Sustainable Dual-Fuel Hydrogen Technology

Discover how CMB.TECH’s dual-fuel hydrogen combustion technology is decarbonizing large marine and industrial applications with the help of metal 3D printing.

Additive manufacturing (AM) is widely considered to be a sustainable production method, but its real impact is in the sustainable innovations it enables. For CMB, it may be the key to achieving a particularly ambitious goal: eliminating their carbon emissions entirely by 2050.

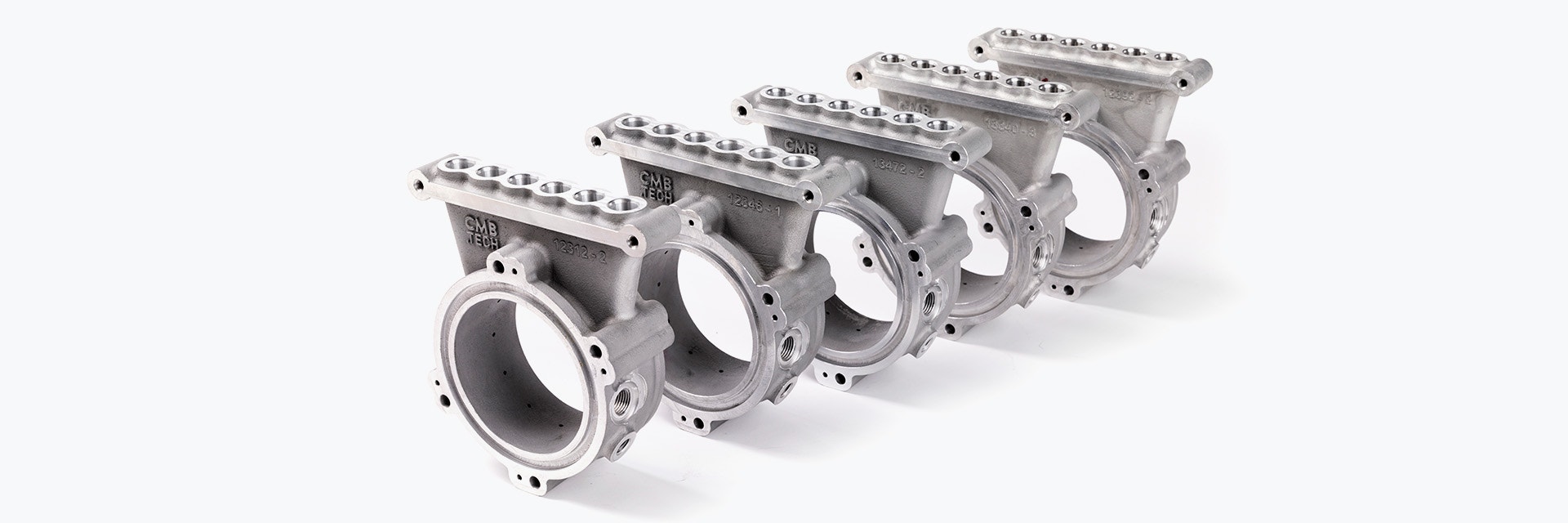

As the cleantech division of CMB, CMB.TECH has spent more than ten years working on a hydrogen-diesel dual-fuel combustion technology to tackle one challenge in particular: decarbonizing large marine and industrial applications. Using this system, the team converts existing diesel combustion engines into dual-fuel combustion engines, where hydrogen is aspirated into the combustion chamber using a 3D-printed injection ring.

Printed in aluminum using selective laser melting (SLM) to match the materials preferred by most engine manufacturers, it fits right into its environment. Not only did this choice result in a very lightweight part — it weighs in at only 654 g — metal 3D printing proved approximately 25% cheaper than casting. For the team at CMB.TECH, the choice was clear.

Scaling up with metal 3D printing

“We realized that the best way to mix the hydrogen and air is with an internal ring structure. It disperses the hydrogen through little holes, and the only feasible way to develop that quickly and easily is through additive manufacturing,” explains Roy Campe, CMB.TECH’s CTO.

“AM changed our whole perception of what was possible and improved the overall concept. We couldn’t easily incorporate those design features into anything made through casting or any other traditional manufacturing process.”

Of course, to make any significant progress on their goals, the team at CMB.TECH needed to be able to produce more than a one-off prototype. After creating a proof of concept through Materialise OnSite, followed by several test pieces, it was time to move into volume production. They turned to the Materialise team for help. Following their specialized NPI process for AM, Materialise manufactured parts that were used to convert a fleet of trucks.

“Everything from machining to the assembly process is much simpler when you can remove the complexity in the build phase by using AM. Materialise takes care of all of it, so we receive a fully finished part,” Roy tells us.

Making a difference

While there is still a long way to go to achieve their 2050 goal, CMB.TECH’s dual-fuel technology already makes a noticeable difference in its current state. The simplified system reduces CO2 emissions by up to 80% in traditional diesel engines, depending on the application and the circumstances.

“So far, the hydrogen injection ring is the best method to provide hydrogen into the air stream in a pre-mixed way. It allows us to offer C02 savings immediately. The demand and the interest from customers to be able to do that is absolutely massive.”

A revolution is on the horizon

The dual-fuel revolution is around the corner, and CMB.TECH is at the forefront of that movement. As orders roll in, CMB.TECH can comfortably produce the parts they need, knowing they can rely on AM and its intrinsic benefits. Short lead times will allow them to order on-demand, lessening risk and storage costs, while Materialise’s strict manufacturing processes ensure they’ll get the quality they require every time.

As with many AM projects, CMB.TECH’s next steps will focus on continued development — optimizing the design, expanding the project to different applications, and reducing materials and costs where possible, all in collaboration with Materialise. It’s a process that depends heavily on a healthy relationship between partners, built on trust and integration.

“For us, it’s essential that we can rapidly come up with design options and alternatives, have them evaluated by the Materialise team, and get guidance on AM to really speed up the process,” says Roy. “Going forward, the designs will just get better and more optimized, ultimately resulting in cheaper parts with less material. So for us, it's a really key part of the future strategy.

“Working with Materialise has been great. The team has always been very responsive and good at meeting deadlines. I believe the whole working relationship has been fruitful and beneficial.”

The feeling at Materialise is equally positive; having worked together since 2019, it is a collaboration that has developed and grown steadily, with increasing integration between the two teams. Materialise’s AM know-how and capacity complemented CMB.TECH’s desire to innovate and drive change at every step. But perhaps more importantly, it is clear that the two companies are driven by a common goal: to make the world a better and healthier place. It’s certainly a partnership that we hope continues throughout CMB.TECH’s entire additive journey.

Share on:

You might also like

Never miss a story like this. Get curated content delivered straight to your inbox.