Materialise e-Stage for Resin

Lower labor costs and realize other significant savings in your resin production with the Materialise e-Stage for resin module. Cut data preparation and finishing times with its powerful algorithm and adjust the extensive parameter list to suit the support structure for your machine, material, and part geometry. Ensure successful builds every time with e-Stage.

Benefits

Streamline data preparation

Decrease your time spent on support design by up to 90% using automated software for stereolithography (SLA) and digital light processing (DLP) machines.

Lower resin consumption

Lower your part’s resin consumption using gusset parameters and recuperate excess raw material thanks to e-Stage’s open structures and excellent drainage capabilities.

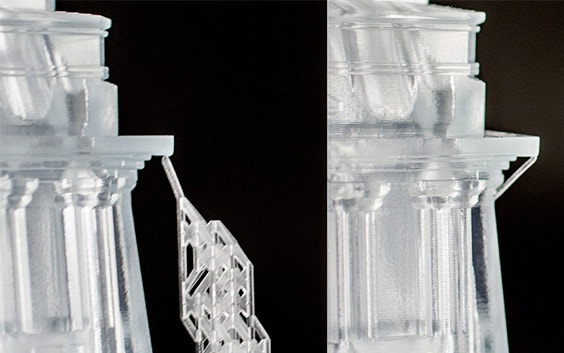

Reduce time spent on support removal

Cut the time spent on support removal by up to 50% with e-Stage’s needle-thin contact points and a grid structure.

Simplify finishing for parts

Reduce the time spent finishing a part, as e-Stage only generates support structures where needed. Furthermore, the unique needle shape minimizes surface damage, requiring less repair work.

Features

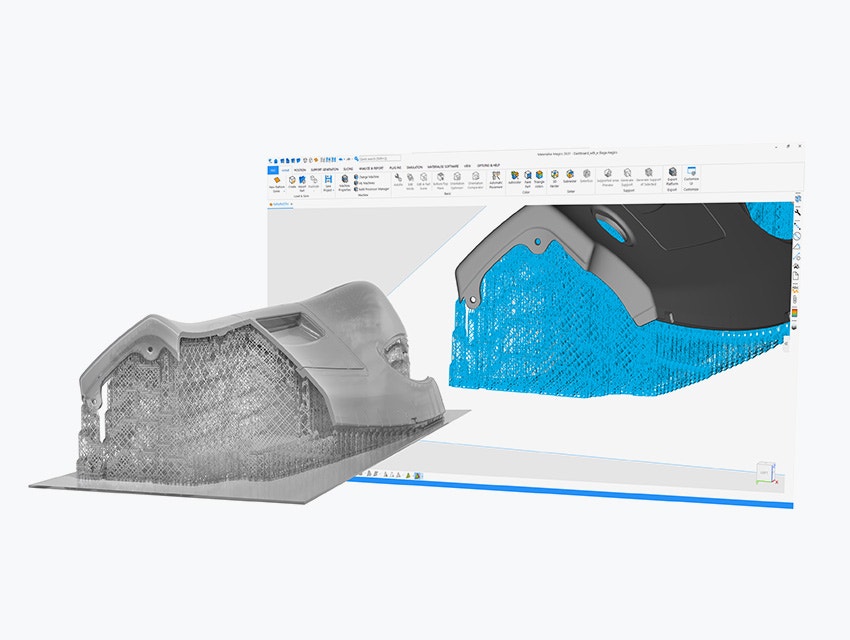

Optimize supports for resin printers

e-Stage automatically generates support structures specifically for resin printers. It reinforces all the necessary surfaces, taking into account the recoater's force during production, and pays special attention to the support connections for tall, thin parts.

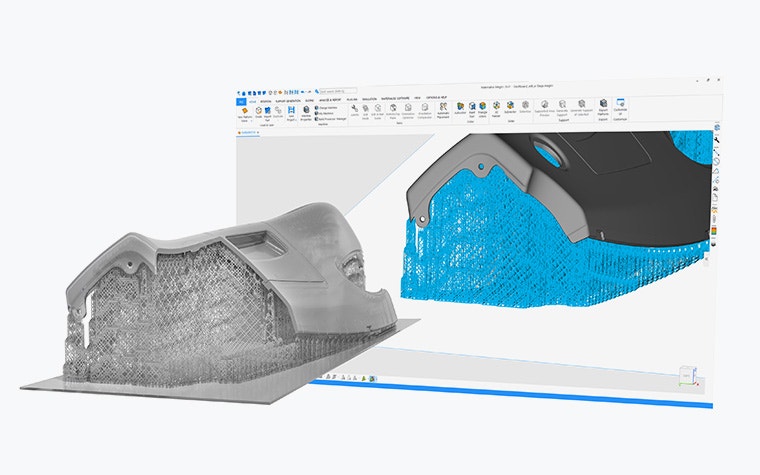

Calculate ideal contact points

e-Stage calculates the optimal placement of your contact points. Diamond structures adapt to the points, navigating around the part to avoid unnecessary contact and reducing finishing time.

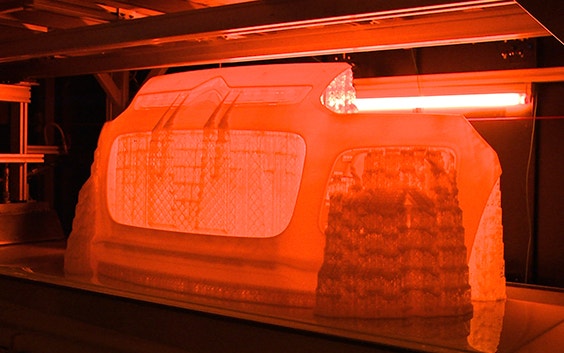

Reduce material consumption

e-Stage's structures are designed to optimize support while minimizing material usage. The open diamond structure prevents resin from getting trapped and the option to add part-to-part support reduces the need for tall supports.

Support stacked parts

Easily generate support around multiple parts by stacking them in the z-direction, maximizing the use of your build volume. With this feature, you can run your machine longer during non-productive hours.

Inspiration

You might also like

Improve production efficiency, automate repetitive tasks, and optimize print success rates with industry-leading data and build preparation software.

Automatically generate metal support structures to reduce human error and save time during build prep and support removal.

Nest parts quickly and efficiently to maximize build capacity, protect small pieces, and reduce human error.