EXPERT INSIGHT

Top Reasons to 3D Print with Polypropylene: Versatility, Accuracy, and 500% Elongation at Break

Polypropylene (PP) is a highly functional plastic commonly used in a wide variety of ways, such as consumer goods, packaging, and automotive applications. So, it was a perfect fit when we added PP to our portfolio of 3D printing materials in 2018. PP, a material option for selective laser sintering technology, offers technical capabilities that provide solutions fit for a variety of industries.

3D-printed parts designed with polypropylene gain many advantages due to the material’s characteristics. Its versatility makes it perfect for a wide variety of applications and it’s as close to injection-molded PP as you can get — but with the benefits that come with 3D printing. If your final product is polypropylene, now you can also test your prototypes in PP while leveraging 3D printing’s cost-effectiveness, freedom of design, and reduced risk.

Numerous possibilities

Boasting such highly regarded capabilities, PP is a wonderful option for many applications. Its versatility, due to tough, flexible, chemical-resistant, and lightweight characteristics, makes it suitable for snap-fit assemblies, living hinges, and clip fingers. With such properties, PP excels in everything from consumer goods to electronics housing to automotive components.

Thanks to this 3D-printed version, the design of PP products can reach new limits. Additive manufacturing allows great freedom of design and manufacturers can take this opportunity to rethink the creation of various PP products to achieve new benefits such as added capabilities or reduced costs.

Accurate prototyping

As a commonly used plastic in manufacturing, it also makes perfect sense for businesses to turn to 3D-printed PP for creating functional prototypes. AM is often the production method that companies turn to for creating prototypes because of advantages like quick iterations and smooth workflows.

“PP exhibits the excellent mechanical properties that we require and its performance is as similar to injection molding as you can get in an AM material.”

— Rickard Camp, Additive Manufacturing Specialist at Volvo Cars

The opportunity to test with the same material that will be used in end-use parts also allows creators to see the prototype behave in a manner that is similar to how the end product will behave. This certainly offers major advantages since the accuracy of a prototype’s performance is greatly improved and decisions regarding the final part can be more definitive.

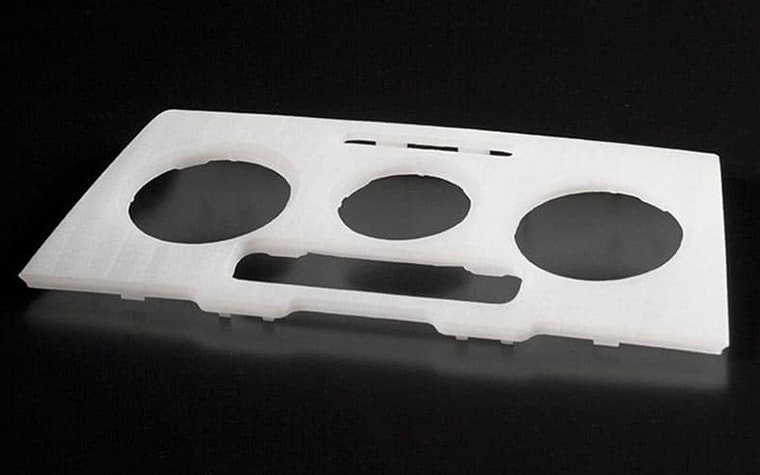

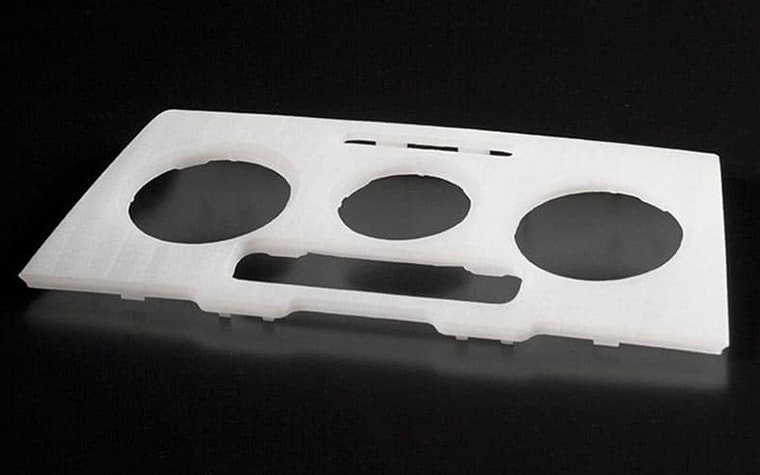

"Thanks to its ease of use, we regularly incorporate 3D-printed polypropylene parts into our concept cars and pre-series cars", according to Rickard Camp, Additive Manufacturing Specialist at Volvo Cars. "PP exhibits the excellent mechanical properties that we require and its performance is as similar to injection molding as you can get in an AM material."

“All markets looking to work with a functional prototype or test part produced in the same material as an end-use part will be keen to associate PP with laser sintering,” says Giovanni Vleminckx, Materialise Research Project Manager. “Having the opportunity to validate designs and test form-and-fit early on, combined with laser sintering lead times, means a pared-down design cycle and shorter time-to-market.”

Impressive capabilities

Manufacturers utilize polypropylene so frequently because of its extensive features and capabilities. 3D-printed PP results in a translucent, off-white finish and is fatigue-resistant with exceptionally high elongation at break — above 500%. Plus, we can print parts up to 500 mm x 500 mm x 480 mm.

With so many incredible capabilities, PP is a well-rounded and highly sought-after material. Its water tightness and high elongation at break make it the perfect choice for bottles and containers that must be leak-proof and have hinges that are opened and closed repeatedly. Additionally, its fatigue resistance and use for snap-fit assemblies also make it ideal for automotive applications.

“It’s tough and stiff enough to stand on its own, but it’s also flexible. PP’s chemical resistance allows it to maintain its integrity in environments where polyamides would be unable to cope,” explains Giovanni. “Due to the nature of the powder, the printed parts are leak-proof for water, even with thin walls.

"Last, but definitely not least, it’s highly reusable in powder form, meaning there’s far less waste and pollution when working that with other materials.”

Share on:

You might also like

Never miss a story like this. Get curated content delivered straight to your inbox.