Consumer Goods

Stand out from the crowd with 3D printing

From proof-of-concept prototypes to premium end-use goods, 3D printing can help you gain a crucial edge in a competitive market. Enhance your product development through rapid time-to-market and an incredible range of technologies, materials, and finishes that make your products stand out from the crowd and ensure you get there first. With low-risk investment costs and the freedom to personalize to an individual’s anatomy or preference, you can diversify your portfolio to grab a share of new and emerging markets.

Why choose 3D printing?

Rapid time-to-market

Keep up with the demands of product development in a fast-paced industry. Create new and exciting products with digital iterations, build true-to-life models for stakeholder sign-off and market testing, and quickly get your finished goods to market with rapid prototyping.

Low-risk innovation

Consumers want to stand out from the crowd — your product needs to do the same. Differentiation and innovation are easy with 3D printing; transform the way a product is designed, stay on-trend with seasonal releases, or venture into new markets with fewer risks and lower entry costs.

Customization and personalization

The personal touch goes a long way. From clothing to orthotics, personalization can improve performance and increase consumer satisfaction and engagement. With 3D printing, you can design and customize unique products for each and every customer.

Why choose Materialise Manufacturing?

Access our incredible portfolio

Take advantage of a wide range of technologies, materials, and finishes to bring your prototype or product to life in the best way possible. Rely on our in-house capacity and online services to print, finish, and deliver high-quality parts quickly and consistently.

Create custom digital workflows

Scan, print, repeat — with our software and manufacturing capabilities, our team can help you create a digital workflow for scan-to-print solutions. With design automation and order flow automation, designing and producing custom products will be simple, affordable, and repeatable.

Develop new AM-ready concepts

Work with our Design & Engineering team to develop innovative new concepts specifically designed to take advantage of additive manufacturing's (AM) design freedom. Whether you require traceability, easy assembly, or anything in between, we can make sure your design is ready from the start.

Ideal materials for consumer goods

PA 12 (SLS)

Technology

Selective laser sintering

Description

PA 12 (SLS) is a general-purpose material that offers excellent long-term stability and good chemical resistance, making it suitable for functional prototypes and end-use parts, as well as consumer goods.

Key characteristics

- Strong, general-purpose material printed without a support structure

- High strength and stiffness

- High chemical, mechanical, and thermal resistance

- Fast Lane service available for online orders of PA 12 (SLS) – Normal finish

- Max part dimensions: 630 x 330 x 550 mm

- Max part dimensions (Fast Lane orders): 270 x 270 x 270 mm

Polypropylene (PP)

Technology

Selective laser sintering

Description

A tough, fatigue-resistant, and lightweight material, polypropylene (PP) is ideal for functional prototypes of snap-fit assemblies or living hinges in automotive components, packaging, and consumer goods.

Key characteristics

- Tough yet flexible material printed without a support structure

- Very high elongation at break (> 500%)

- Lightweight and fatigue resistant

- Max part dimensions: 480 x 480 x 430 mm

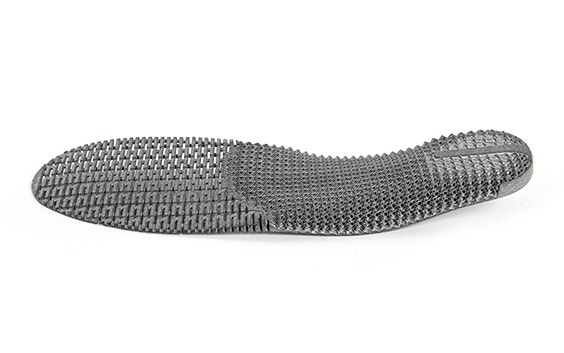

Ultrasint TPU 90A-01

Technology

Multi Jet Fusion

Description

Ultrasint TPU 90A-01 combines durable elasticity with good wear and abrasion resistance, making it ideal for prototypes and end-use applications that require good shock absorption.

Key characteristics

- Rubber-like material printed without a support structure

- Durable elasticity with high elongation at break

- Good wear and abrasion resistance, and good shock absorption

- Max part dimensions: 370 x 274 x 375 mm

PA 12 (MJF)

Technology

Multi Jet Fusion

Description

With higher density and lower porosity than laser-sintered polyamide, this strong, general-purpose material is ideal for precision forms and works equally well for functional prototypes or end-use parts.

Key characteristics

- Strong, general-purpose material printed without a support structure

- High density and low porosity, with crisp textures and detailed surfaces

- Near-isotropic mechanical properties

- Max part dimensions: 370 x 274 x 375 mm

Poly1500

Technology

Stereolithography

Description

Poly1500 is a durable, resilient material that offers high surface quality and dimensional accuracy. With properties similar to polypropylene, it is ideal for functional prototypes.

Key characteristics

- Similar properties to polypropylene

- Good durability, impact resistance, and heat resistance

- Among the largest printing volumes of stereolithography materials

- Max part dimensions: 2,000 x 700 x 788 mm

ProtoGen White

Technology

Stereolithography

Description

ProtoGen White's resilience, surface quality, and thermal properties make it suitable for general-purpose applications such as RTV molding patterns, highly detailed parts, and durable concept models.

Key characteristics

- Similar properties to ABS

- Resilient material with good surface quality

- Among the largest printing volumes of stereolithography materials

- Max part dimensions: 2,000 x 700 x 788 mm

TuskXC2700T

Technology

Stereolithography

Description

Designed to simulate ABS, TuskXC2700T is a strong material that offers high resolution and a smooth surface. It is ideal for water-resistant prototypes and high-end finished models. Transparent finishes possible.

Key characteristics

- Strong, water-resistant material with properties similar to ABS and PBT

- Great surface quality, with transparent finishes possible

- Among the largest printing volumes of stereolithography materials

- Fast Lane service available for online orders of TuskXC2700T – Basic finish, Support marks removed, or Support marks removed + sandblasted

- Max part dimensions: 2,000 x 700 x 788 mm

- Max part dimensions (Fast Lane orders): 100 x 100 x 100 mm

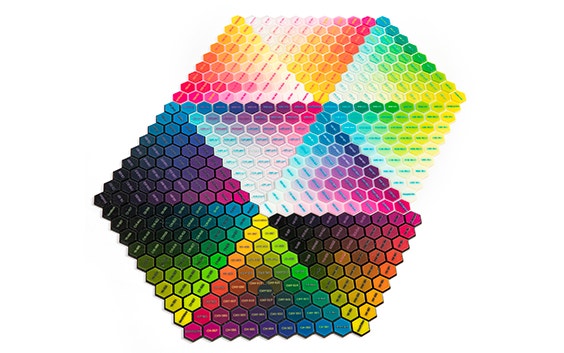

Vero

Technology

PolyJet

Description

Vero is a rigid, opaque material that offers excellent detail and can be blended with other PolyJet materials to determine toughness, rigidity, or translucency. Available in multiple colors.

Key characteristics

- Rigid, general-purpose material

- High level of surface detail

- Can be combined with other PolyJet materials to alter toughness, rigidity, or translucency

- Max part dimensions: 490 x 390 x 200 mm

Typical 3D printing applications for consumer goods

Small appliances

Move through every stage of the product development cycle quickly and affordably; develop new prototypes or proof of concepts, test your market, and apply what you learn by easily reworking your digital designs.

Beauty and hygiene products

As an industry calling out for personalization or new application methods, the personal care market is always looking for ways to differentiate. 3D printing will help you offer it. Develop new prototypes quickly, create innovative new packaging, add customization options, or enhance your product’s performance with this technology.

Sporting goods

One size fits all really fits no one, and sporting goods are no exception. With 3D printing, you can provide strong, lightweight, and unique-looking products and gear for athletes and hobbyists alike. Explore the potential of mass customization with bespoke products tailor-made for each customer’s anatomy.

Photo © ENGO Eyewear

Fashion accessories

From luggage prototypes to fashion accessories, 3D printing is an increasingly popular choice for product designers. The ability to move from prototype to serial production quickly and affordably, coupled with strong, high-quality materials and the potential for custom designs, make it ideal for this market.

Photo: Stealth Bag Designboom - Photo © Marta Cherednik

Our products and services for consumer goods

Ready to start your project with us? Discover our solutions, ideal for your industry.

Transform your product development cycle and get the best possible products to market faster. Get unbiased advice and dedicated support from teams committed to your success.

Get direct 24/7 access to the technologies and materials you need to bring your designs to life. Instant quotes, short lead-times, and easy checkout.

Innovate and speed up your manufacturing in collaboration with our experts. Rely on our full range of in-house technologies suitable for all industries and applications.

Build your success on a platform of software tools that efficiently manage and control the 3D printing process, allowing you to meet the highest standards of the most demanding industries.

Work with our experts to translate your business challenges into 3D printing opportunities and identify the applications that can help you meet your needs.

Inspiration

Get inspired for your next project by looking at how others have used 3D printing to create consumer goods.

Other industries we work in

Navigate the future of aerospace with shorter lead times, more affordable small series production, and the unrivaled design freedom that additive manufacturing can offer.

From quick, performant prototypes and visual models to small series manufacturing and automotive tooling, tick every box by bringing 3D printing into existing or new production workflows.

Enter a new era of more sustainable, on-demand manufacturing where creativity and innovation have no boundaries and where quick time-to-market, and zero stock-risk, boost business agility.