Technology

Stereolithography

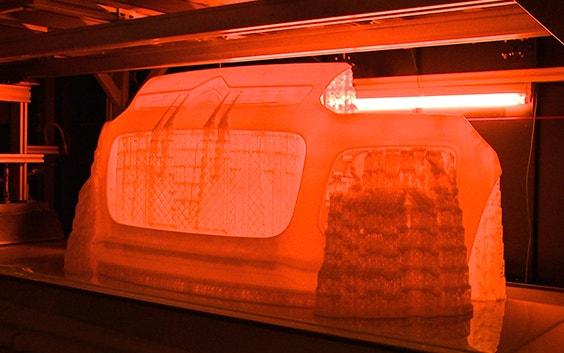

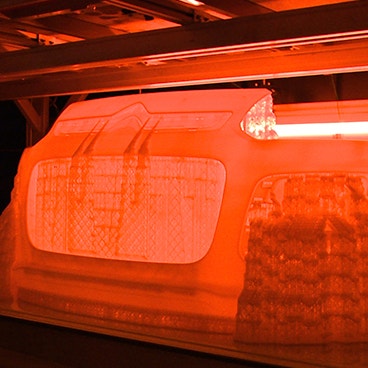

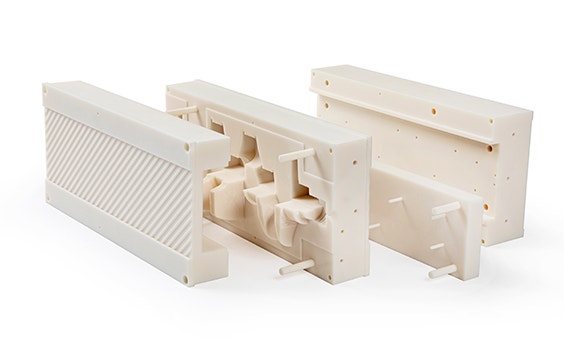

Stereolithography is one of the most widely used 3D printing technologies. Its impeccable surface quality, ability to produce fine details, and wide selection of materials make it ideal for high-quality visual models and prototypes, complex aesthetic parts, and masters for techniques like vacuum casting and lost wax casting.

Why work with Materialise Manufacturing?

With unrivaled expertise in stereolithography, your project is in safe hands. We help you take full advantage of the flexibility, design freedom, and speed of 3D printing to meet your needs, and thanks to our patented Mammoth printers, you can even print parts up to two meters long in a single build. Our NextDay service, available for selected materials and finishes when you order online, means your model can be on your desk within 24 hours.

Discover applications of stereolithography

Technical specifications

| Maximum build dimensions | Dimensions are unlimited as components may be composed of several sub-parts. The maximum build envelope is 2,100 x 700 x 800 mm |

| Standard accuracy | ±0.2% (with a lower limit on ±0.2 mm) |

| Layer thickness |

|

| Minimum wall thickness | 1 – 3 mm |

| Surface structure | Unfinished parts typically have a smooth surface with visible building layers; various post-production finishes are possible |

Materials

Choose from a broad selection of materials when you come to Materialise for your stereolithography projects.

Poly1500

Technology

Stereolithography

Description

Poly1500 is a durable, resilient material that offers high surface quality and dimensional accuracy. With properties similar to polypropylene, it is ideal for functional prototypes.

Key characteristics

- Similar properties to polypropylene

- Good durability, impact resistance, and heat resistance

- Among the largest printing volumes of stereolithography materials

- Max part dimensions: 2,000 x 700 x 788 mm

ProtoGen White

Technology

Stereolithography

Description

ProtoGen White's resilience, surface quality, and thermal properties make it suitable for general-purpose applications such as RTV molding patterns, highly detailed parts, and durable concept models.

Key characteristics

- Similar properties to ABS

- Resilient material with good surface quality

- Among the largest printing volumes of stereolithography materials

- Max part dimensions: 2,000 x 700 x 788 mm

TuskXC2700T

Technology

Stereolithography

Description

Designed to simulate ABS, TuskXC2700T is a strong material that offers high resolution and a smooth surface. It is ideal for water-resistant prototypes and high-end finished models. Transparent finishes possible.

Key characteristics

- Strong, water-resistant material with properties similar to ABS and PBT

- Great surface quality, with transparent finishes possible

- Among the largest printing volumes of stereolithography materials

- Fast Lane service available for online orders of TuskXC2700T – Basic finish, Support marks removed, or Support marks removed + sandblasted

- Max part dimensions: 2,000 x 700 x 788 mm

- Max part dimensions (Fast Lane orders): 100 x 100 x 100 mm

TuskXC2700W

Technology

Stereolithography

Description

Designed to simulate ABS, TuskXC2700W is a strong material with a rapid lead time. It is ideal for water-resistant and functional prototypes. Also available in clear.

Key characteristics

- Strong, water-resistant material with properties similar to ABS and PBT

- Fast Lane service available for online orders of TuskXC2700W – Basic finish, Support marks removed, or Support marks removed + sandblasted

- Max part dimensions: 350 x 350 x 350 mm

- Max part dimensions (Fast Lane orders): 100 x 100 x 100 mm

Taurus

Technology

Stereolithography

Description

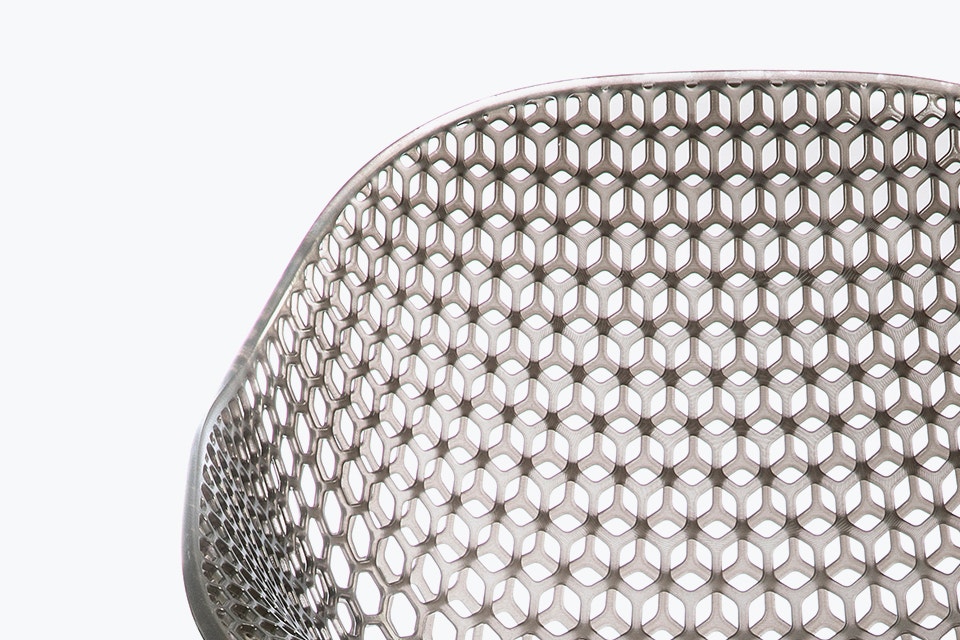

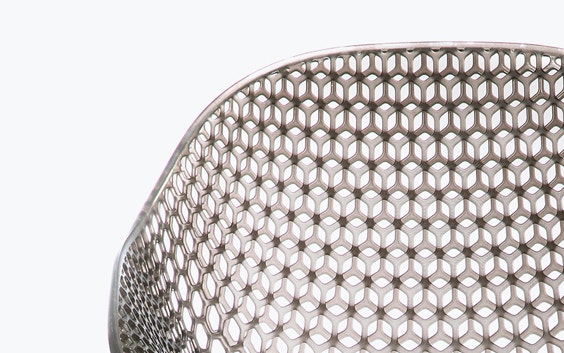

Taurus has the look and feel of an injection-molded part, offering strong mechanical properties and high surface detail. It's an ideal choice for form-, fit-, and function-testing, as well as functional prototypes.

Key characteristics

- Injection-molded look and feel

- Strong mechanical properties

- High surface detailing

- Max part dimensions: 480 x 480 x 560 mm

Xtreme

Technology

Stereolithography

Description

Xtreme is a tough, general-purpose material with high impact strength, high elongation, and excellent surface quality. With properties close to ABS, Xtreme is ideal for functional prototyping.

Key characteristics

- General-purpose material with properties similar to ABS

- High impact strength and elongation at break

- Excellent surface quality

- Max part dimensions: 480 x 480 x 560 mm

Tusk Somos SolidGrey3000

Technology

Stereolithography

Description

Exclusive to Materialise, Tusk Somos SolidGrey3000 combines very high stiffness and impact strength. It is ideal for functional prototypes, durable concept models, robust scale models, as well as end-use parts.

Key characteristics

- High degree of stiffness

- High impact strength

- Available exclusively at Materialise

- Max part dimensions: 2,000 x 700 x 788 mm

PerFORM

Technology

Stereolithography

Description

A resin with ceramic particles, PerFORM offers high stiffness and strength, as well as excellent heat resistance and detail. It is ideal for prototyping and for rapid tooling for injection molds.

Key characteristics

- Stiffness comparable to glass fiber-reinforced polycarbonate

- High thermal resistance and excellent detail resolution

- Superior sidewall quality

- Max part dimensions: 800 x 800 x 585 mm

Work with us: discover our products and services

Want to bring stereolithography into a future project? Discover the services that can help you do it.

Get direct 24/7 access to the technologies and materials you need to bring your designs to life. Instant quotes, short lead-times, and easy checkout.

Transform your product development cycle and get the best possible products to market faster. Get unbiased advice and dedicated support from teams committed to your success.

Innovate and speed up your manufacturing in collaboration with our experts. Rely on our full range of in-house technologies suitable for all industries and applications.

Work with our experts to translate your business challenges into 3D printing opportunities and identify the applications that can help you meet your needs.

Build your success on a platform of software tools that efficiently manage and control the 3D printing process, allowing you to meet the highest standards of the most demanding industries.

Train and learn

Get more from your next project with helpful resources dedicated to stereolithography.