Industrial

Prototyping Services

Rapid iteration made easy

Prototypes are an essential part of the product development cycle. Additive manufacturing (AM) offers a fast and cost-effective way to create the prototypes you need at every stage of the process, from design verification to form, fit, and function testing. Materialise’s prototyping services can help you bring your ideas to life faster and more efficiently thanks to our extensive, in-house, AM resources and know-how, and teams who are as committed to the success of your project as you are.

Why choose Materialise?

All the choice you need

Our number one priority is finding exactly the right solution for your prototypes. That’s why you’ll receive unbiased access to all the leading technologies, along with a wide, in-house, selection of materials and finishes, including production-grade materials. And with over 140 industrial-grade machines, you can rely on our scale to deliver your parts quickly.

We make the complex simple

Turning great ideas into successful products is exciting and challenging work. Our specialized teams are passionate about 3D printing and have the breadth and depth of experience to make your prototyping journey as straightforward as possible. Whatever stage you’re at, you can be sure your project is in safe hands.

A complete service

Because creating prototypes is often about more than just printing, we offer full-service prototyping so you can centralize your entire project with one trusted partner. Whether you need bespoke finishes, assembly, or high-quality painting, we can deliver your prototypes ready for design validation and verification.

Quality in everything we do

We strive for quality across every aspect of our business, and it’s why customers choose us again and again. Our more than 30 years’ experience with 3D printing means we’ve mastered the prototyping process, and our teams have an in-depth understanding of the factors that really matter to the success of your project.

Quality assurance for prototyping

| Quality requirements |

|

| Tolerances |

|

| Mechanical properties |

|

| Surface quality |

|

| Quality documentation |

|

| Process control |

|

Support from a dedicated team

We are committed to your success

You’ll be supported by a dedicated project engineer from quote to delivery, ensuring you have access to the right specialists at every stage. From advice on design and the optimal combination of technology, material, and finish, to help with build preparation, they’ll leave no stone unturned.

We speak your language

Our teams have helped hundreds of customers advance their product development with all kinds of prototyping, so we’re well-positioned to understand your challenges and guide you towards the best results. We also mean it literally — our customer support team speaks 12 languages and are located in your region.

Design for additive manufacturing

Create, test, and refine prototypes with our team

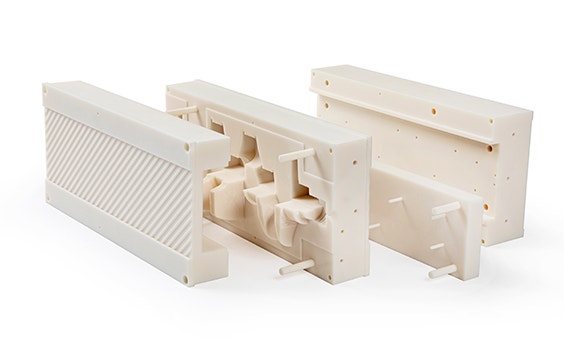

Functional models

By taking advantage of the design freedom offered by additive manufacturing technologies, our Design & Engineering specialists can integrate mechanical functions directly into the design in order to build functional models — without the need for tooling.

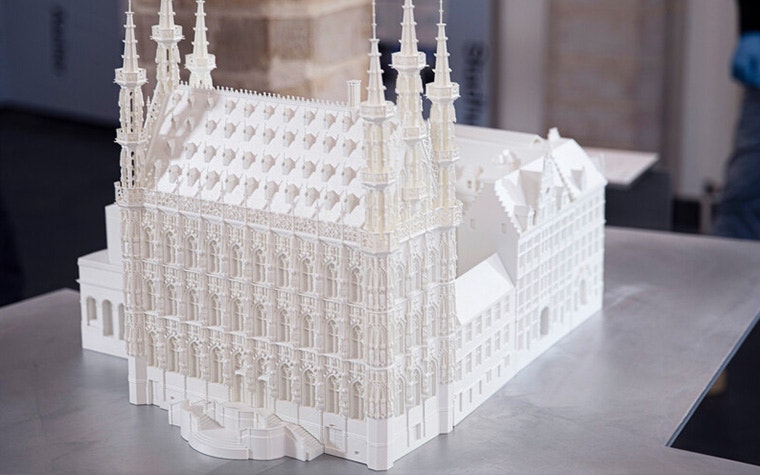

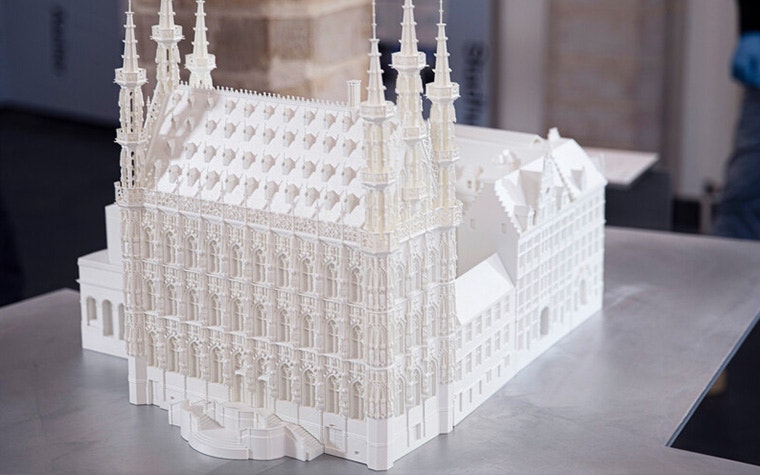

Scale models

Our engineers can help you build a scale model of almost anything, big or small. Scanned data can be imported for scaling, ensuring the 3D files are print-ready for production and provide an accurate representation of the original model. Structural reinforcements can be added as needed to ensure the stability of the maquette.

3D scanning

3D scanning can play an important role in your design process by acting as a starting point for 3D modeling. Using Materialise 3-matic software, our engineers can make design modifications or even new designs at mesh level, allowing you to bring creative ideas to life without having to start from scratch.

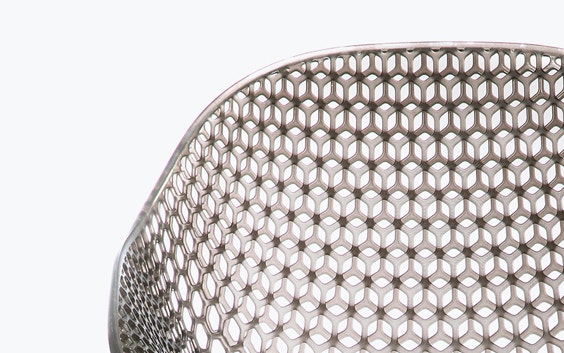

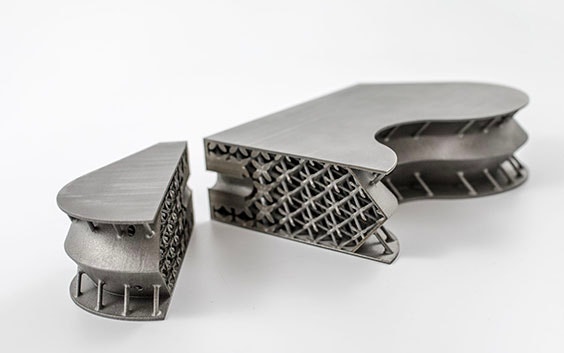

Lattice structures

Complexity doesn’t cost extra with additive manufacturing, and lattice structures are a great example of this. Whether your goal is to optimize costs, reduce weight, enhance function and performance through cushioning, or create a visually stunning piece, we can help you leverage this powerful tool that’s beyond the reach of most conventional manufacturing methods.

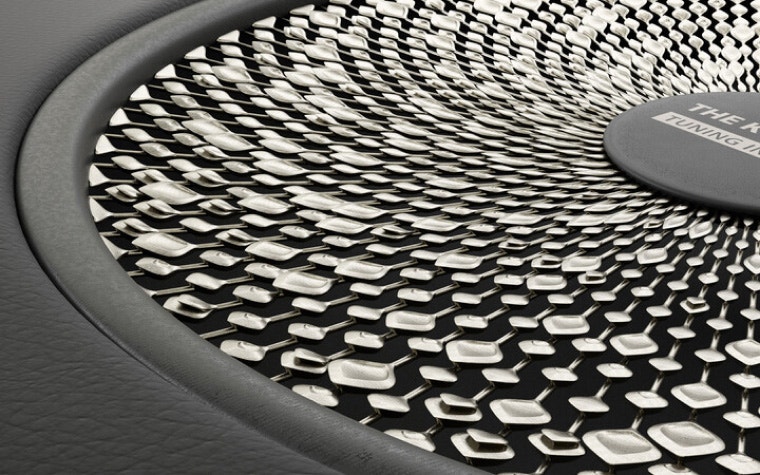

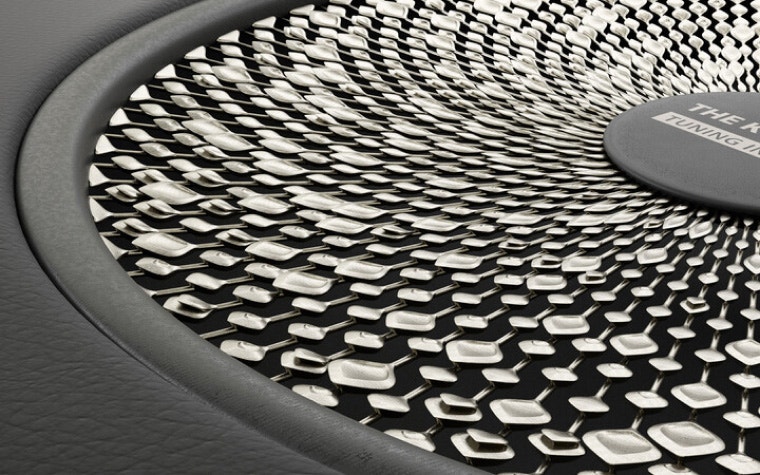

Digital texturing

Adding texture to your 3D-printed part can transform it into a final product, whether it’s to improve grip, aerodynamics and tactility, or for aesthetics. You can also mimic the look of materials like leather or wood. Our engineering team can apply surface textures, patterns, or perforations directly on your CAD file using Materialise 3-matic software, meaning you don’t need to spend valuable time adding textures in post-production.

Prototyping technologies

Discover our extensive range of technologies to create prototypes that perform exactly as you need them to.

Prototyping materials

Choose from our range of materials to create parts with the mechanical properties, functional characteristics, or aesthetics you need.

PA 12 (SLS)

Technology

Selective laser sintering

Description

PA 12 (SLS) is a general-purpose material that offers excellent long-term stability and good chemical resistance, making it suitable for functional prototypes and end-use parts, as well as consumer goods.

Key characteristics

- Strong, general-purpose material printed without a support structure

- High strength and stiffness

- High chemical, mechanical, and thermal resistance

- Fast Lane service available for online orders of PA 12 (SLS) – Normal finish

- Max part dimensions: 630 x 330 x 550 mm

- Max part dimensions (Fast Lane orders): 270 x 270 x 270 mm

PerFORM

Technology

Stereolithography

Description

A resin with ceramic particles, PerFORM offers high stiffness and strength, as well as excellent heat resistance and detail. It is ideal for prototyping and for rapid tooling for injection molds.

Key characteristics

- Stiffness comparable to glass fiber-reinforced polycarbonate

- High thermal resistance and excellent detail resolution

- Superior sidewall quality

- Max part dimensions: 800 x 800 x 585 mm

ABS

Technology

Fused deposition modeling

Description

Known for its toughness, durability, and affordability, ABS is one of the most widely used industrial thermoplastics. It is suitable for prototyping, tooling, and end-use parts.

Key characteristics

- Tough, durable material

- High impact strength

- Up to 80% of the strength of injection-molded ABS

- Fast Lane service available for online orders of ABS White/Black – Normal finish

- Max part dimensions: 300 x 300 x 300 mm

- Max part dimensions (Fast Lane orders): 250 x 250 x 300 mm

Aluminum (AlSi₁₀Mg)

Technology

Metal 3D printing

Description

The strength, thermal properties, low weight, and flexible post-processing of this aluminum alloy, AlSi₁₀Mg, make it ideal for prototyping and manufacturing in industries such as automotive and aerospace.

Key characteristics

- Offers the largest printing volume of all metal 3D printing materials

- Lightweight, with good strength-to-weight ratio

- High thermal and electrical conductivity

- Suitable for post-machining

- Max part dimensions: 500 x 280 x 345 mm

Ultrasint TPU 90A-01

Technology

Multi Jet Fusion

Description

Ultrasint TPU 90A-01 combines durable elasticity with good wear and abrasion resistance, making it ideal for prototypes and end-use applications that require good shock absorption.

Key characteristics

- Rubber-like material printed without a support structure

- Durable elasticity with high elongation at break

- Good wear and abrasion resistance, and good shock absorption

- Max part dimensions: 370 x 274 x 375 mm

Rubber-like Polyurethanes

Technology

Vacuum casting

Description

Offering a range of different material properties, our rubber-like polyurethanes can be used with silicone molds to produce high-quality prototypes or small series of end-use parts.

Key characteristics

- Excellent surface quality and detail, resembling TPE, TPU, and silicone rubber

- Ideal for applications that need good shock absorption

- Cost-effective way to produce prototypes or small series of end-use parts

- Max part dimensions: 1,900 x 900 x 750 mm (maximum part volume: 10 liters)

ABS-like Polyurethanes

Technology

Vacuum casting

Description

Offering a range of different material properties, our ABS-like polyurethanes can be used with silicone molds to produce high-quality prototypes or small series of end-use parts.

Key characteristics

- Excellent surface and detail, with injection-molded look and feel

- Flame-retardant, food-safe, and UV-stable materials available

- Cost-effective way to produce prototypes or small series of end-use parts

- Max part dimensions: 1,900 x 900 x 750 mm (maximum part volume: 10 liters)

PE/PP-like Polyurethanes

Technology

Vacuum casting

Description

Offering a range of different material properties, our PE/PP-like polyurethanes can be used with silicone molds to produce high-quality prototypes or small series of end-use parts.

Key characteristics

- Excellent surface and detail, with injection-molded look and feel

- Tough and lightweight with a wide range of finishes available

- Cost-effective way to produce prototypes or small series of end-use parts

- Max part dimensions: 1,900 x 900 x 750 mm (maximum part volume: 10 liters)

Inspiration

Get inspired for your next project with a look at how AM has transformed industries around the world.