industrial

Manufacturing Services

On-demand production made easy

Through our manufacturing services, you can access our extensive additive manufacturing (AM) facilities and knowledge to create the high-quality parts you need, on time and to your specifications. Together, we’ll go from concept to finished part with a time-proven process you can trust.

Why choose Materialise?

Experts in AM

As industry leaders in AM for both prototyping and serial production, you can safely rely on our expertise. From aerospace to consumer goods, we’ve helped transform manufacturing across a range of industries for over thirty years. Whether you’re a start-up or enterprise company, we can do the same for you.

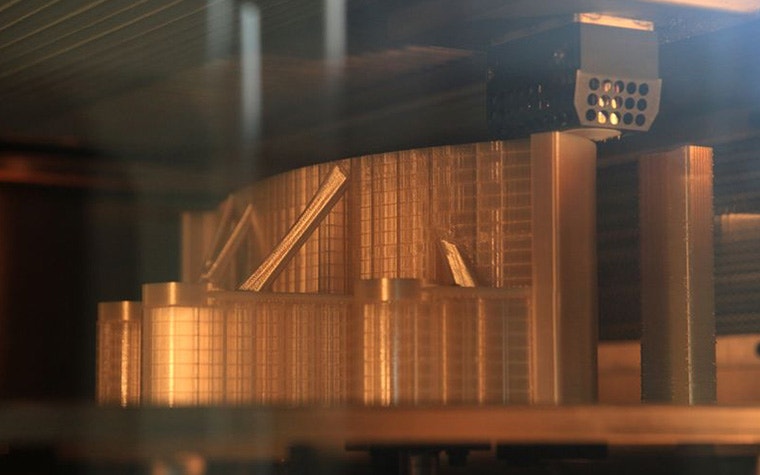

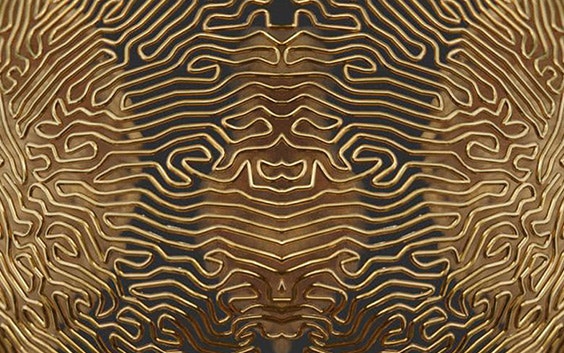

Industry-leading infrastructure

With a comprehensive range of production-grade materials and technologies, a team that knows how to use them, polymer and metal competence centers, and more, we can fully support you. You’ll find all you need for the production, post-production, and quality inspection of end-use parts in-house at Materialise Manufacturing.

Scaling up alongside you

From small series to series production, we have the expertise, range, and capacity to help you each step of the way. As one of the largest and most complete AM facilities in Europe, we’re well-versed in scaling production to the next level for our customers.

Repeatable and reliable

With a tried-and-tested NPI process, quality management, and dedicated procedures, you can trust that every product you get is exactly what you ordered — traceable, repeatable, and reliable. We align with your industry-specific quality and safety standards and validate every part according to your specifications to ensure you receive the service you deserve.

Quality comes first

We don’t just believe in doing it right. We believe in doing it better. We offer advice on part quality, printability, and improving part performance through (re)design for AM. Strict quality and reliability metrics are applied across all of our manufacturing centers. We’ll document every step of the inspection and validation process, ensuring your project is always in safe hands.

A wealth of AM material data

Access process control data gathered over the years in our role as an EASA 21.G-certified production facility, including thousands of data points from hundreds of production builds for many materials, machines, and technologies. Rely on real-life performance data such as density, tensile properties, and more to support your design for AM.

Quality and certifications

Materialise means quality. It’s a commitment we make to every project. By adhering to our own internal quality policy and the demands of key regulatory certifications, we deliver high-value services and products that satisfy the needs of our customers, suppliers, and partners.

EN 9100 for metal

Our metal parts production meets the industry-recognized quality, traceability, and risk management standards defined by the International Aerospace Quality Group (IAQC) and certified by BSI.

EN 9100 for polymers

For companies who prefer to issue their own Form 1 accreditation or for flight-ready parts that do not need Form 1 accreditation, we can also manufacture polymer parts with EN 9100 certification.

ISO 9001

All non-flying parts like production tools and prototypes are produced in accordance with our ISO 9001-certified quality management system, which has a strong focus on customer satisfaction and continuous improvement.

ISO 14001

Our environmental management system ensures our workflows adhere to ISO 14001. We're moving towards a sustainable future, focusing on minimizing waste, efficient water and energy use, reducing raw material usage, and much more.

EASA Part 21G

As a Production Organization Approval (POA) holder, we can issue Form 1 accreditation with manufactured parts and take the burden of certification off your shoulders.

Quality assurance for series production

| Quality requirements |

|

| Tolerances |

|

| Mechanical properties |

|

| Surface quality |

|

| Quality documentation |

|

| Process control |

|

A dedicated team

We put the right people in the right places

At Materialise Manufacturing, you don’t just access industry-leading infrastructure but also a team that lives and breathes AM. They speak your language and will love your project just as much as you do, making every experience simple, convenient, and successful. This unique combination of service and expertise is the secret to delivering exceptional results.

We guide you from start to finish

When you begin a project with us, a dedicated project engineer will be on-hand to guide you every step of the way and help you choose the right combination of material, technology, and finish. They’ll call on production, Design & Engineering, and finishing specialists to find the best solution for you.

An additive manufacturing NPI

Our proven NPI process carries each idea from concept to scaled production successfully. Together, we’ll determine your project’s requirements, assess design feasibility, and select the optimal materials and finishes. We will identify any unique development needs and validate the design through initial production runs, providing you with all you need to move into serial production. Transparent, collaborative, and tailored to AM, it’s a process you can rely on to deliver the parts you need.

Full-service AM

For many projects, printing is just the beginning. From obtaining industry-specific documentation to post-machining and assembly, organizing it all can be complicated. But not at Materialise Manufacturing. Whether through our own facilities or a close-knit network of trusted suppliers, you’ll find every service you need to create ready-to-use parts right here.

Design for additive manufacturing

Work with our Design & Engineering team on everything from ideation to file preparation and ensure that your file is ready and optimized for 3D printing from the get-go.

Product development

If you want to unlock the benefits additive manufacturing offers for your particular project, it makes sense to design towards them from the outset and fully understand the interplay between your application, production technologies and material requirements. By involving our DfAM-specialized designers in your ideation phase, you’ll get expert insight and advice that’s tailored to your specific needs to get your project off to the best possible start.

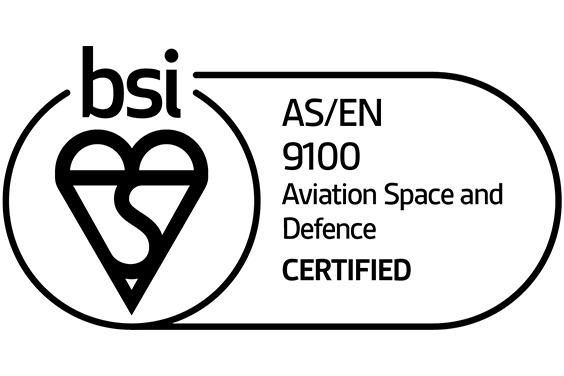

Procedural modeling

When a 3D model is too complex, too large, or contains too much repetition to be created manually using 3D modeling software, procedural modeling can be an ideal solution. This algorithm-based technique produces 3D models from a set of rules, making it possible to easily adjust parameters and repeat rulesets to create any kind of model.

(Re)Design for AM

Whatever your goals for additive manufacturing are, you’ll only reach them if you design towards them from the start. Sometimes however the manufacturing technology is not the first thing on your mind at the start of a project. For those times we offer our expertise to re-design for AM. We can also validate part performance through simulations.

Lightweighting

Our experts can help with optimizing the weight of your part while preserving its original properties. We can apply lattice structures and/or use (post-)topology optimization tools to (re)construct the design for an optimal part that is ready for 3D printing at the right cost.

Reverse engineering

When you’re optimizing the design of a legacy part or replacing a broken component, reverse engineering can save days or weeks of manual design. Thanks to our in-house scanning systems and engineering expertise, we can translate 2D drawings or physical parts into 3D CAD models, and go straight from scanned or CAD data to analysis and other CAE applications.

Manufacturing grade materials

Fast-track your next project with a wide range of 3D printing materials, ideal for serial production.

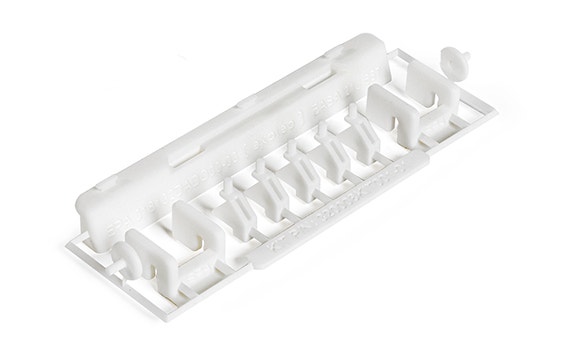

Polypropylene (PP)

Technology

Selective laser sintering

Description

A tough, fatigue-resistant, and lightweight material, polypropylene (PP) is ideal for functional prototypes of snap-fit assemblies or living hinges in automotive components, packaging, and consumer goods.

Key characteristics

- Tough yet flexible material printed without a support structure

- Very high elongation at break (> 500%)

- Lightweight and fatigue resistant

- Max part dimensions: 480 x 480 x 430 mm

PA 2210 FR

Technology

Selective laser sintering

Description

PA 2210 FR is a high-performance, UL Blue Card-certified polyamide containing a halogen-free flame retardant. Excellent long-term stability and good chemical resistance make it ideal for functional prototypes or end-use parts.

Key characteristics

- Strong material printed without a support structure

- Flame retardant — UL Blue Card-certified (UL 94 rating of V-0 at 3 mm wall thickness), CS/FAR 25.853 compliant

- High chemical, mechanical, and thermal resistance

- Max part dimensions: 280 x 280 x 550 mm

PA 2241 FR

Technology

Selective laser sintering

Description

PA 2241 FR is a high-performance, flame-retardant polyamide. Its excellent long-term stability and good chemical resistance make it ideal for functional prototypes or end-use parts.

Key characteristics

- Strong material printed without a support structure

- Flame retardant — CS/FAR 25.853 compliant, available in Airbus certified grade, according to AIPI 03-07-022

- Excellent long-term stability and high chemical resistance

- Max part dimensions: 630 x 330 x 550 mm

PA-AF (Aluminum Filled)

Technology

Selective laser sintering

Description

PA-AF blends polyamide with aluminum to produce strong, stiff parts resistant to temperatures of up to 130°C. With a metallic appearance, it is ideal for models, rapid tooling, and fixtures.

Key characteristics

- Strong, stiff material printed without a support structure

- Slightly sparkly metallic appearance, suitable for post-machining

- High temperature resistance (130°C)

- Max part dimensions: 630 x 330 x 550 mm

PA 12 (SLS)

Technology

Selective laser sintering

Description

PA 12 (SLS) is a general-purpose material that offers excellent long-term stability and good chemical resistance, making it suitable for functional prototypes and end-use parts, as well as consumer goods.

Key characteristics

- Strong, general-purpose material printed without a support structure

- High strength and stiffness

- High chemical, mechanical, and thermal resistance

- Fast Lane service available for online orders of PA 12 (SLS) – Normal finish

- Max part dimensions: 630 x 330 x 550 mm

- Max part dimensions (Fast Lane orders): 270 x 270 x 270 mm

PA-GF

Technology

Selective laser sintering

Description

PA-GF blends polyamide with glass beads to offer higher durability, stiffness, and thermal resistance. It is ideal for prototypes or applications where temperature or wear resistance are key.

Key characteristics

- Strong, stiff material printed without a support structure

- High tensile strength, wear resistance, and temperature resistance (110°C)

- Suitable for post-machining

- Max part dimensions: 630 x 330 x 550 mm

PA 12 (MJF)

Technology

Multi Jet Fusion

Description

With higher density and lower porosity than laser-sintered polyamide, this strong, general-purpose material is ideal for precision forms and works equally well for functional prototypes or end-use parts.

Key characteristics

- Strong, general-purpose material printed without a support structure

- High density and low porosity, with crisp textures and detailed surfaces

- Near-isotropic mechanical properties

- Max part dimensions: 370 x 274 x 375 mm

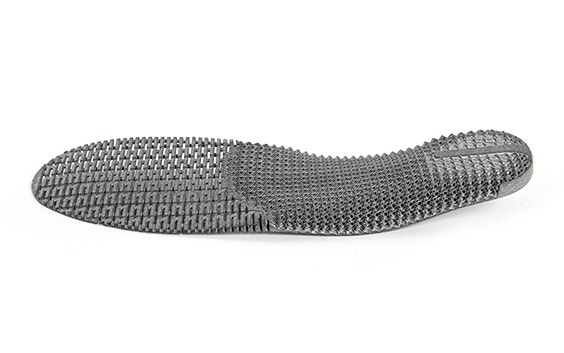

Ultrasint TPU 90A-01

Technology

Multi Jet Fusion

Description

Ultrasint TPU 90A-01 combines durable elasticity with good wear and abrasion resistance, making it ideal for prototypes and end-use applications that require good shock absorption.

Key characteristics

- Rubber-like material printed without a support structure

- Durable elasticity with high elongation at break

- Good wear and abrasion resistance, and good shock absorption

- Max part dimensions: 370 x 274 x 375 mm

Inspiration

Get inspired for your next project with a look at how AM has transformed industries around the world.