CASE STUDY

QualiCal METRO: 3D Printing Innovation for the Lime Industry

Italian engineering company QualiCal saw the opportunity to use 3D printing to innovate a key element of the lime production process. Partnering with Materialise, the firm developed a novel shaft level indicator that slashes downtime, offering the potential for increased revenue of up to €1,400,000.

Lime is one of the most important materials in modern life. Used in applications ranging from construction to cosmetics, it is estimated that the average EU citizen consumes around 150 grams of lime per day through products containing, or manufactured using, the age-old substance. Lime production is big business but it’s also highly competitive, making it essential to increase profitability, improve product quality, and reduce operational inefficiency.

Coupled with an industry-wide drive to utilize the benefits of digitization and realize Industry 4.0 ambitions, Italian engineering company QualiCal saw these challenges as an opportunity to innovate a key area of production: limestone level indication.

The challenge

Take QualiCal’s new shaft level indicator prototype to the next level

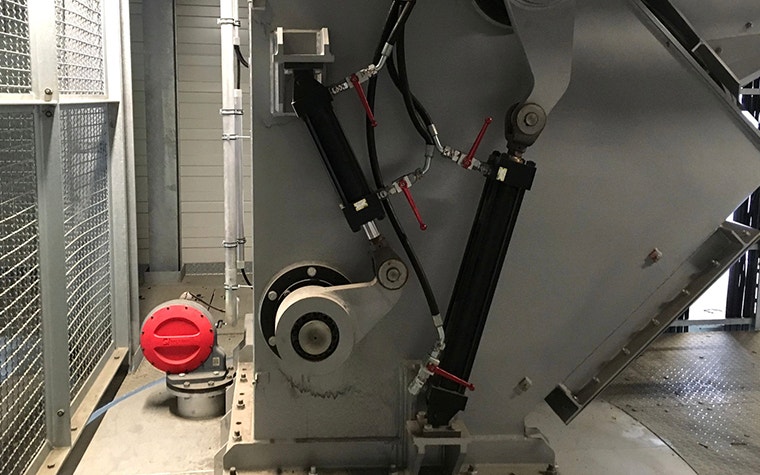

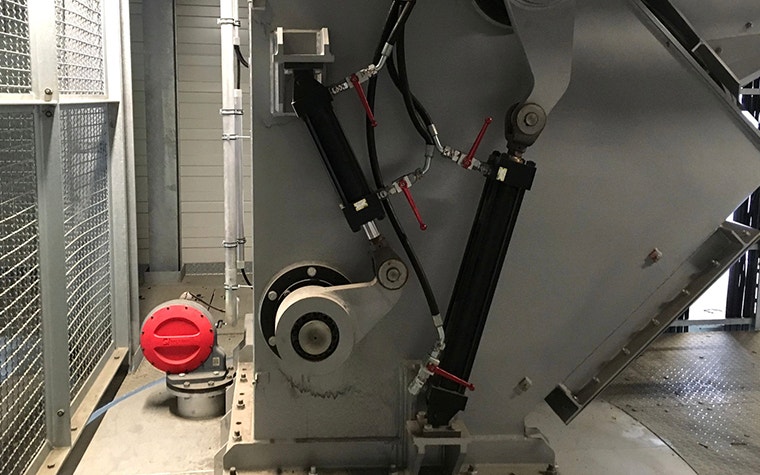

Accurately measuring the limestone levels inside kilns during the lime production process is essential as it dictates operational actions needed to optimize final product quality. Traditionally, a shaft level indicator (SLI) is used: a drum powered by an electronic motor and hydraulics lays down a counterweight to maintain physical and continuous contact with the material bed in order to feed back constant and accurate limestone level measurements.

“The shaft level indicator is the heart of the lime production process — what was clear to us was that the heart could beat faster and stronger.”

— Francesco Cella, Technical Director at QualiCal

Though universally adopted, the solution is far from ideal. The SLI’s complex mechanical design, with many moving parts, often results in ‘friction failure’ or data inaccuracy. The unit is also susceptible to powder clogging from the dusty kiln environment. Cumulatively, the issues make SLIs the primary cause of unplanned plant downtime, costing the average facility over €20,000 a year in production losses.

Francesco Cella, Technical Director at QualiCal, says: “The shaft level indicator is the heart of the lime production process — what was clear to us was that the heart could beat faster and stronger. Introducing a new brushless motor, continuous torque control, and simplifying mechanical parts — eliminating the need for extra hydraulics — we developed the first METRO prototype. Having field-tested the unit in a HeidelbergCement Synthesis kiln we knew the concept was sound.

“But we also knew we were still being shackled by the confines of tradition. Our next step was to look at how performance could be improved through advanced manufacturing techniques, in particular at how structures and materials possible only through 3D printing could take METRO to the next level.”

The solution

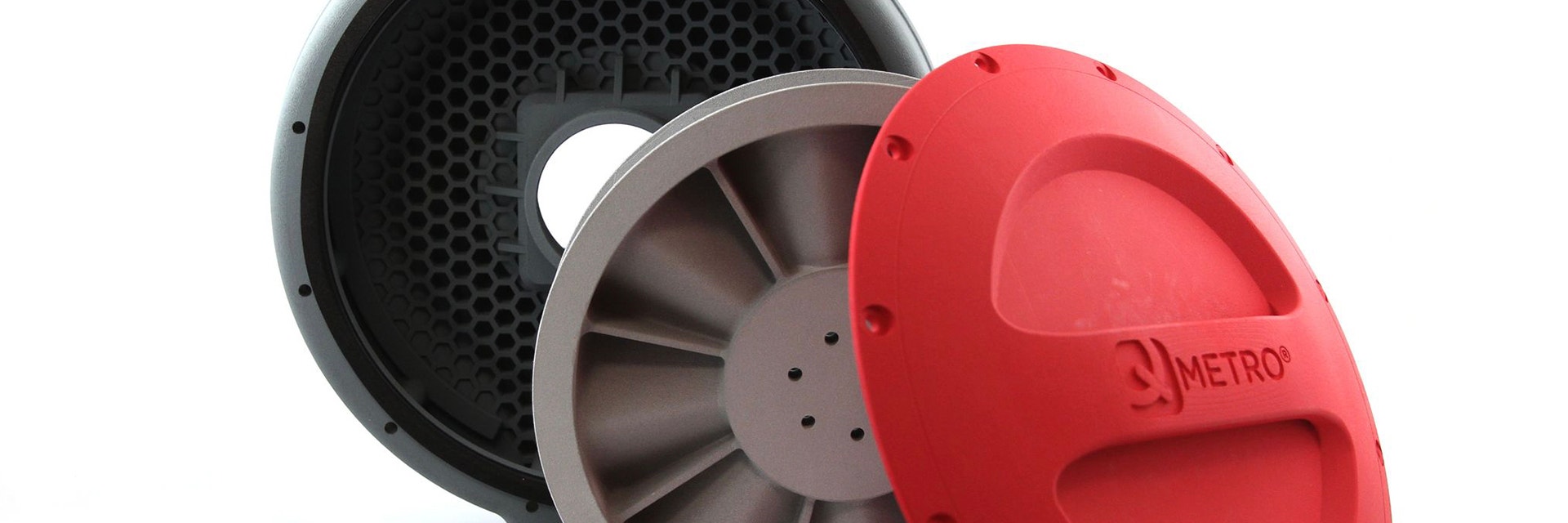

3D-printed high-performance plastics with honeycomb structures

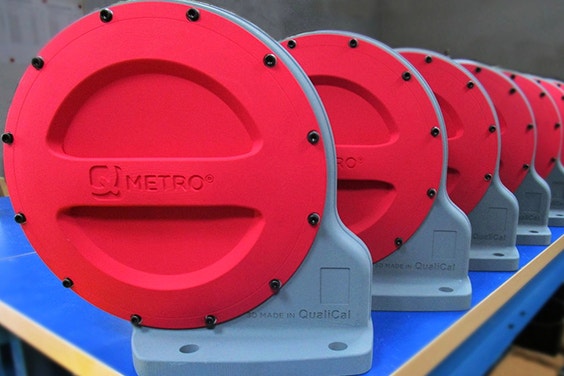

Alessio Esposti, Account Manager for Materialise Italy, and his team at Materialise took up QualiCal’s challenge. Within just one month they had re-imagined QualiCal’s METRO prototype, optimizing its geometry and composition to create a smaller, lighter solution.

“When QualiCal came to us with the metal prototype, we knew that 3D printing design techniques could help optimize and reduce individual components to further minimize points of physical failure and operational malfunction, and quickly came up with the design concept to take forward for development.”

Using honeycomb structures and high-performance plastics — fiber/aluminum reinforced nylon — the team was able to reduce the instrument size by half (drum diameter from 500 mm to 250 mm), distributing strength throughout the unit to improve resistance and durability. Front-to-back screw channels, impossible to create using traditional milling techniques, removed any need for connection with the inner environment, ensuring excellent resistance to pressure from processed air.

The result

A highly accurate, virtually maintenance-free instrument

Using high-performance plastics means the METRO indicator can be used at extremely high kiln temperatures, and unlike with traditional steel SLIs, there are no longer any issues with oxidization. Also, because the optimized geometry of the instrument reduces opportunities for dust ingress and pressure build-up, the 3D-printed METRO is virtually maintenance-free.

“With a production cost equal to that of traditional shaft level indicators, the savings generated by reduced unplanned downtime and maintenance are exactly that, real savings.”

— Carlo Cella

During a six-month pilot deployment in an active kiln, the new-look METRO required no maintenance and, when inspected, showed no signs of needing any in the near future. Gearboxes no longer need lubricating. Parts no longer wear out from friction. Overheating no longer occurs from mechanical wear and tear. All for the same unit cost as producing the old, traditionally manufactured steel SLI instrument.

Reducing mechanical parts and optimizing design has also improved sensor accuracy, meeting QualiCal’s commitment to enhanced digital feedback for improved production in line with Industrial Internet of Things (IIoT) principles.

As QualiCal CEO Carlo Cella explains, the cost efficiencies are substantial. “3D printing is often seen as the innovative but expensive option. That simply isn’t the case here. With a production cost equal to that of traditional shaft level indicators, the savings generated by reduced unplanned downtime and maintenance are exactly that, real savings.

“Our calculations show that the solution could save lime producers around 120 €/tpd every year — extrapolated for the lifetime of the equipment we think that this simple change could increase revenue for these businesses by some €1,400,000. Add to that the future benefits of being able to print and even adapt spare parts on-site, avoiding the need to rely on holding stock or long-lead-time supplies, and the advantages really stack up.”

Share on:

This case study in a few words

Machinery and equipment

Selective laser sintering

PA-AF

PA-GF

Design optimization

Affordable short series production