EXPERT INSIGHT

30 Years of Materialise: Automated Factories and Production Are Driving Sustainable Practices

When 3D printing was in its early days, the few Materialise employees would hit start on processing a CAD file and then pick up their ping pong paddles and settle in for a nice long ping pong tournament. Hours later, the CAD file would be converted into an STL, and they could finally get started on the first of the many painfully slow iterations to come.

Fast forward 30 years through a blur of technological advances from specialized software to computing power — we have arrived at a time where exceedingly complex files are computed in a cloud quickly and efficiently then translated into a ready-to-print file in just minutes with much less manual work. Not just that, but the files have been enhanced to have the most efficient build and positioning and the least amount of support structures needed. As we step into the future of 3D printing, we see more and more automated processes that lead to better print accuracy and improve sustainability with less waste in the industry.

As Materialise celebrates its 30th anniversary, we look back at the most meaningful innovations over the company’s history with a series of blog posts. In this post, we’re reflecting on some of our factory and production practices and how they relate to our vision of a better and healthier world.

It all started with one man, one machine, and one material

In 1990, Fried Vancraen recognized the extraordinary potential of a new technology he had just seen at a research facility in Bremen, Germany — 3D printing. Realizing the importance of this technology, Fried boldly invested all his savings into one machine and launched Materialise. This precious machine was around where the original ping pong battles reigned.

The biggest difference between today and 30 years ago is the sheer range of materials, software, and machines. In the beginning, there was just one material that you could print on the one machine, and it was extremely brittle. If a printed object was dropped, it would shatter. Its main functionality was to be used for prototyping and ‘show and tell’ purposes.

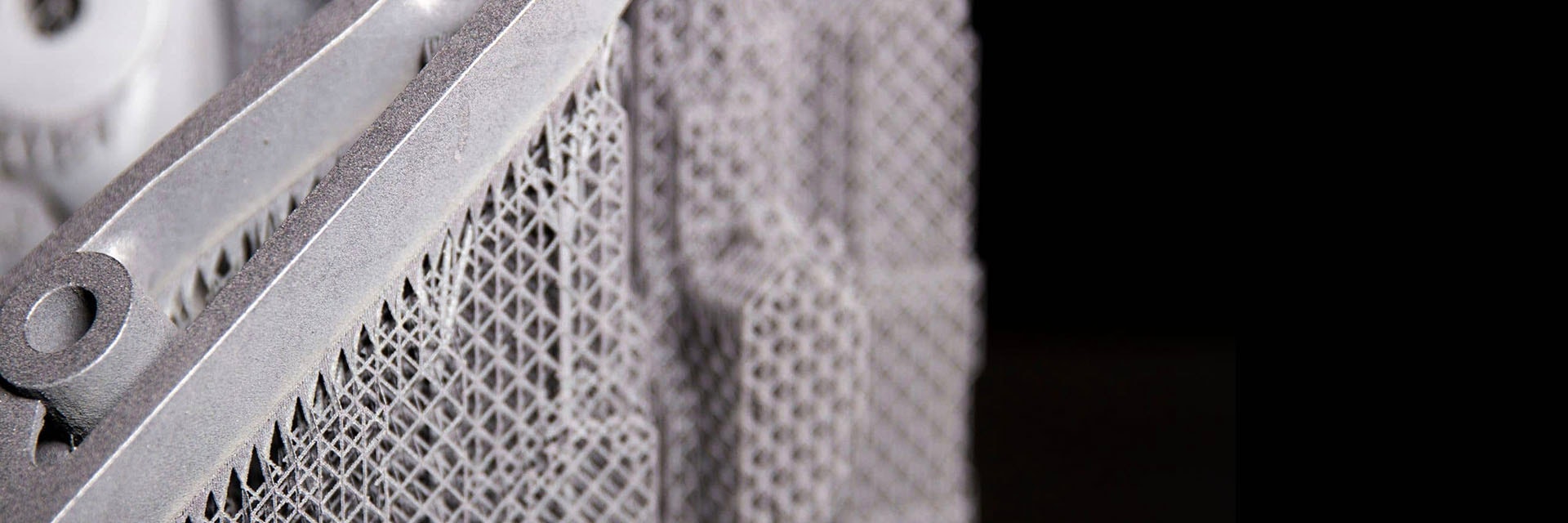

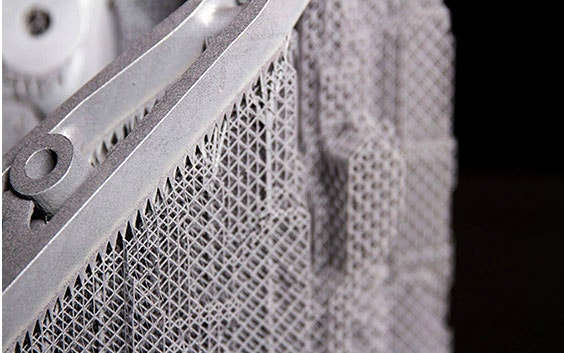

Today, we have a multitude of materials available that range from many different plastics to metals. Materialise now has over 180 professional machines spilling out more than a million parts a year. With the numerous options between tech and materials, this means that parts can be produced that have much higher functionality. With all the progress that has brought us to present day, we can talk about all kinds of manufacturing applications that are now possible through 3D printing. But these are only possible with the right kind of software to deal with the complexity of printing today’s builds.

Origin of the software unit

Early on, there was the realization that without better software to process the files, they would never be able to use 3D printing technology efficiently. As Bart Van der Schueren, CTO of Materialise, and one of the first employees says, “The biggest issue from the start was the non-existence of decent software tools to get the CAD data to something actually printable. So that’s what we worked on. Our big belief was that if you take away the hurdles and make the technology more accessible, then the whole industry moves forward together. We would be able to make a bigger impact than if we just remained a service bureau.”

And so they started working on Magics software that would enable more efficient builds for the entire industry by translating CAD files into STL files for printing. It also helped in repairing files and editing designs so that problems could be caught before even printing them out. With this in mind, Fried committed the company to only creating software that was machine and technology-neutral so they could co-create with other companies in the future rather than locking away innovation under a brand name.

“Our big belief was that if you take away the hurdles and make the technology more accessible, then the whole industry moves forward together. We would be able to make a bigger impact than if we just remained a service bureau. ”

— Bart Van der Schueren, CTO of Materialise

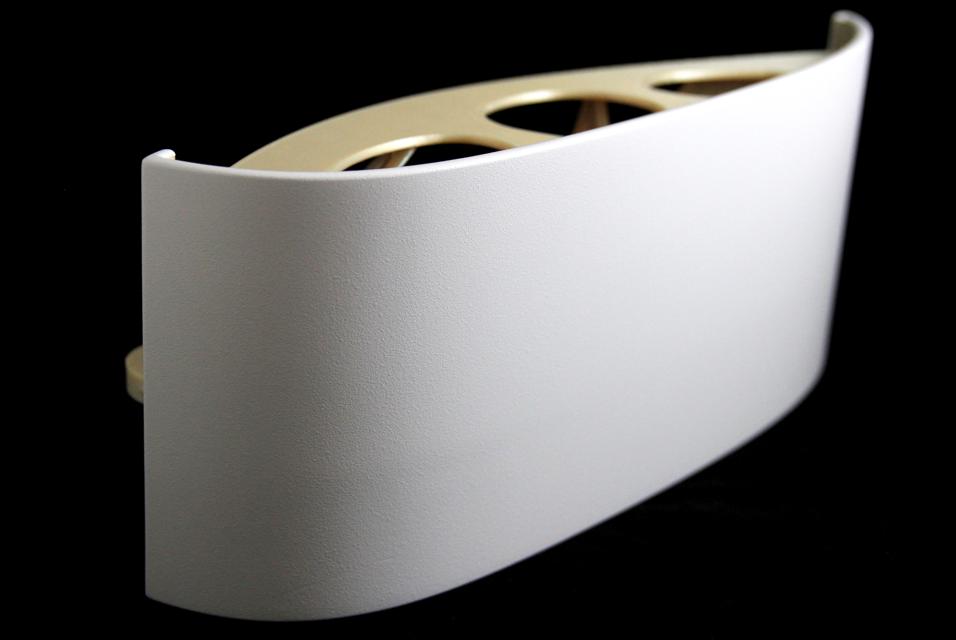

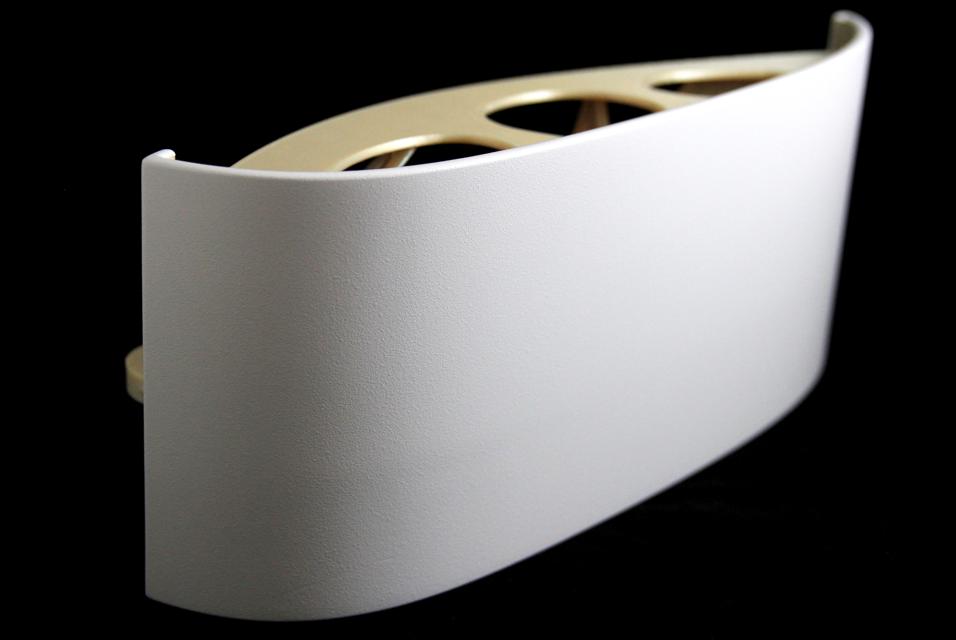

Secure prototyping

3D printing got its start in the prototyping world. Customers need to verify designs and perform form, fit, and function tests in a cost-efficient way before bringing the design into traditional manufacturing. This continues today with our rapid prototyping service where our project management teams help find optimal solutions and our Design & Engineering (D&E) team can support in getting early design files ready for 3D printing. The D&E team can also solve developmental challenges by re-designing products for better performance that reduces assembly (so-called function integration) or make the part more lightweight, etc.

Prototyping has always been a secretive process as customers work to unveil their newest designs and advances. As their partner, Materialise has had to earn their trust by setting systems in place that make our platforms secure. Additionally, as the designs and files have been getting larger and more complex, they needed a solution to be able to both quickly process and store these massive files.

Scaling up in the cloud

Again, the company had to evolve and innovate to respond to the need for security and enough computing power to process these large files. As time went on, computers improved and we developed better software, enabling us to process files faster and automate the process. Ping pong games while waiting for files became a thing of the past.

Despite this, the files continued getting more complex, and to meet the demand, we looked to cloud computing. This meant that rather than relying on just one computer, we were able to access the power of entire servers all at once. This became an irreversible trend throughout all industries as it was necessary for scaling up. Technological advancements, such as encrypted communications and management processes, ensured that customer data remains secure.

Making the impossible, possible

Staf Wuyts, another one of our long-term employees and the current CAD Manager for Stereolithography (SLA) recalls, “Fried said that one day we were going to build a machine that can print something the size of the human.” People were surprised but didn’t write him off. Eventually, in 2000, Materialise was actually able to build an SLA machine that could do just that, and eventually even printed bones to size for a Mammoth skeleton!

The early 2000s brought this advent of printing large pieces using these SLA machines. The problem was that the builds were so labor intensive that it needed one person per machine just to handle designing all the supports needed. It was just not scalable, and Bart challenged the software department to create a module for Magics that would automatically generate the most optimal and least material-intensive support structure for the build. The software department came up with e-Stage which would do just that, but the problem was that the production team was hesitant to test it out. Each of these huge builds cost up to tens of thousands of euros, and if they tried it out and it didn’t work, it would all be wasted. The software was shelved for the moment.

Staf further explains, “When a customer comes in with something that we think is impossible, we make an arrangement with the customer to test out if it’s possible.” With this as a guiding principle, one day they were approached by an artist who wanted to print a very large and complex sculpture that involved hundreds of flying bees in the shape of a human. Bart made the bold decision to finally test out e-Stage because otherwise they would have to turn away the project as the design was much too complex. The sculpture was printed and, in fact, the finishing team marveled that it was so much easier to remove the supports because they were much thinner than usual. It could have been a costly and wasteful test, but instead, it transformed the way that production has worked ever since. The automation of support generation saved hours of labor for the finishing team and made it so that we no longer needed one person designing support per machine. This module is still helping our software customers reduce costs and improve productivity even today.

Traceable from start to finish

Manufacturing is much more than just production volumes — it’s about quality, reliability, and repeatability. Over the years, we have been able to develop certified and traceable parts for both the medical and aerospace sector. For medical, we are creating personalized implants for patients to help minimize further procedures while for aerospace, we offer certified additive manufacturing (AM) of flight-ready parts.

For AM environments, traceability is essential. It allows you to monitor when and with what material a part was made and is the digitalization of inventory. Software such as Materialise Streamics supports businesses in digitalization as it helps control the end-to-end workflow — from part submission to part building to finishing. Every step is traceable and accessible digitally.

Sustainable production becomes a reality

Today, on a professional 3D printer, yields from 90 – 95% are considered good, but the remaining 5 – 10% are considered waste. Software and machines continuously evolve to try to further limit this amount of waste. Recently, we introduced Bluesint technology into our production that prints Bluesint PA 12, consisting of 100% reused powder — reducing the amount of waste in production and helping AM become more sustainable.

Especially during the COVID pandemic, we have seen more and more localized production as supply chains have been disrupted. In a world where supply routes can suddenly shut down, it makes smart business sense to be able to source product locally and AM enables this. Sustainability has become less of a buzzword and more of a reality to survive as a business.

Going forth, we see this tide of digitalization and automation enduring. From more specialized software to using AI algorithms to search for the best build orientation, to better post-processing, we will continue to focus on integrating more automation into production. Additionally, we see the ongoing evolution of materials so that 3D printing continues from just being a rapid prototyping technology to reliable end-use parts. Minimizing production scrap, using less material for lighter but stronger parts, simplifying supply chains, and optimizing the transportation of goods are all trends that we see continuing as we make strides towards a more sustainable future for all.

Share on:

You might also like

Never miss a story like this. Get curated content delivered straight to your inbox.