EXPERT INSIGHT

How Software Will Keep up with the Rise of Large, Complex LPBF Metal 3D-Printed Parts

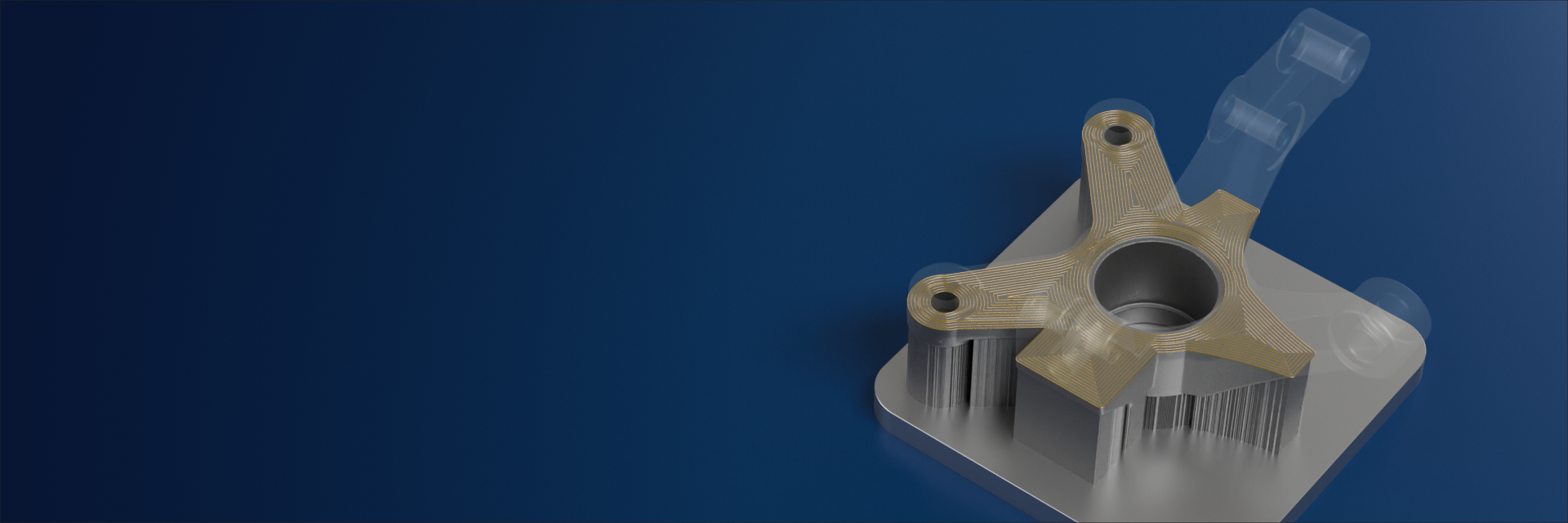

The metal 3D printing industry has seen impressive advances over the last five years due to growing customer demand for bigger, more complex parts — especially when it comes to laser powder bed fusion (LPBF) applications. Consequently, we’ve seen a rise in the development of metal 3D printers with expanded build volumes and increased laser capacity.

Of course, as a digital manufacturing method, this means that software needs to evolve to keep up with the larger, complex files that accompany the increasing size of printers. In parallel, high-performant engineering teams are leveraging new CAD and DfAM tools to create geometries with native beam lattices and implicit design features. Traditionally, importing and processing non-mesh files could pose processing and timing challenges — and sometimes they are even impossible to render and slice. Software that communicates build instructions to the printers will carry a heavy load in addressing these challenges. In this article, we’ll explore how Next-Generation Build Processors can help us overcome these hurdles.

6 challenges with traditional software

Classic Build Processors process data in batches by slicing, zoning, and hatching the job file. However, this approach can become a significant bottleneck for such elaborate parts. Let’s take a look at the six most common challenges associated with this approach.

1. Long pre-processing times

As file sizes increase, users may experience significant lags and even crashes while processing job files. This bottleneck can severely hamper productivity and delay time-to-market.

2. Inefficiency

Multi-optic 3D printers have the potential for high throughput, but without good distribution of the workload over multiple lasers, manufacturers won’t get the most out of their machine utilization rates. Lack of access to experienced engineers who can refine toolpaths hinders manufacturers from optimizing Build Processors and unlocking their printers’ full capabilities.

3. Lack of quality

Meeting the strict mechanical property requirements for many industrial applications remains a persistent challenge in additive manufacturing (AM). We often see this result in an inability to consistently print parts right the first time and, therefore, high scrap rates. This obviously negatively impacts both costs and time-to-market.

4. Inability to slice beam lattices and implicit designs

3D printing software has struggled to process advanced beam lattices and implicit designs, which often require large, unwieldy CAD or mesh files. Tools like nTop offer innovative implicit modeling to characterize these complex geometries more efficiently. However, until now, nTop designs couldn’t be natively processed by widely used data and build preparation software like Magics, leading to time-consuming or impossible slicing workflows.

5. Integration with computer-aided manufacturing (CAM) software

To achieve peak productivity, users need a streamlined connection to CAM software like Magics. Most workflows available today don’t allow for this type of connection, but it’s key to easily generating better job files tailored to 3D printing system’s specific capabilities.

6. Missing opportunities for new applications

To truly capitalize on AM’s design freedom, manufacturers need to meet highly custom requirements like complex features, thin walls, and large implicit files, which depend on factors like 3D printer build volume, material options, and end-use application needs.

Why we need to prioritize solutions to these challenges

To set their 3D printing productions apart from the competition, companies need to focus on three points: improving time-to-market, boosting 3D printer productivity, and increasing the return on their 3D printer investments. Developing unique intellectual property around specific materials and use cases is another key way to remain unique in a crowded market.

With software like Magics and Next-Generation Build Processors, manufacturers can achieve optimized toolpaths to help productions reach this point and unlock AM’s full transformative potential.

“Our recent benchmark tests on our LiM-X260 dual laser with the Next-Gen Build Processor have 45x faster slicing and hatching time,” shares Huanhuan Zhao, Production Manager at Tianjin LiM. “What once took 15 hours to process now takes less than 20 minutes.”

Driving productivity and quality improvements with the next generation of software

With the rapid evolution of modern hardware, modular, configurable, and customizable software is the ideal way for manufacturers to achieve peak productivity, quality, and application flexibility. To meet this need, we’ve introduced Next-Gen Build Processors, built on 30+ years of AM expertise, a proven track record of supporting hundreds of 3D printer models with our classic Build Processor offering, and our Build Processor Software Development Kit (BP SDK) architecture. This modular framework allows users to leverage and customize proven build file generation algorithms and push their printers’ limits. They can even integrate proprietary IP with existing software.

“With this highly flexible platform, users can control up to 170 parameters, fully utilizing Renishaw’s open-source parameter ethos,” explains David Ewing, Product Marketing Engineer at Renishaw. “However, it maintains a user-friendly interface, using predetermined parameters so the build can be prepared in a few simple steps.”

The value of our Next-Gen Build Processors integration capabilities has already been proven with Wärtsilä’s high-performance, 3D-printed cylinder head. By connecting to nTop’s powerful new implicit modeling kernel and corresponding file format, Wärtsilä was able to manufacture this previously unprintable design that achieves of weight reduction of 60% with Nikon SLM Solutions’ NXG XII 600 3D printer.

9 ways to drive productivity

To make the benefits more tangible, let’s look at nine ways to achieve a more efficient production process.

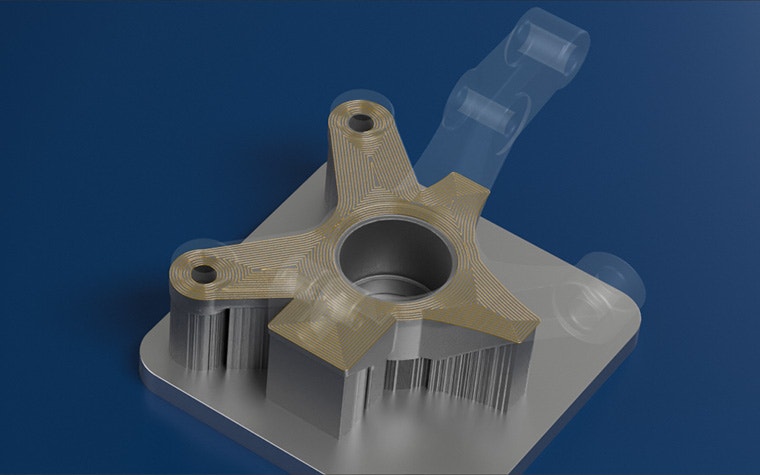

1. Variable processing

This tool segments parts into multiple discrete z-sections. Users can then implement specific build strategies or slice thicknesses tailored to the specific geometric requirements of each section.

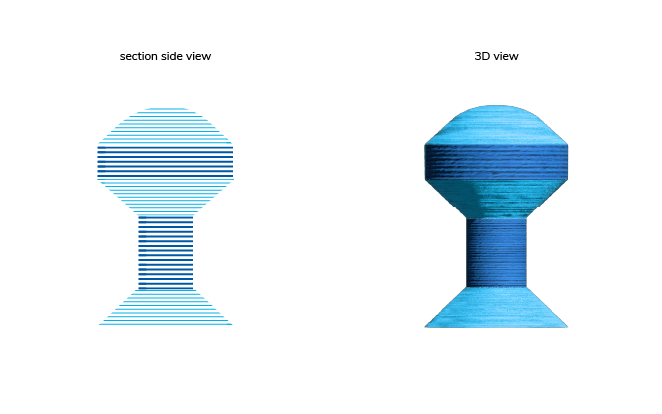

2. Adaptive slicing

This advanced capability enables faster printing without compromising quality. How does it work? By automatically dividing a part into varying thicknesses based on its geometry. For example, if a part has a curvature, adaptive slicing uses thin layers for a smooth surface finish.

On the other hand, it can utilize thicker layers for straight sections of parts, potentially doubling the slice height compared to the curved areas. This way, the printer can print the straightforward regions more quickly and maintain fine resolution for complex, curved areas.

3. Multi-processing

This feature divides the workload and processes multiple slices simultaneously. With the power of multi-threaded or multi-core CPU architectures, this parallel processing approach can dramatically accelerate the calculation speed. The performance boost scales with the number of CPU cores available, allowing the software to take full advantage of more powerful PC hardware.

4. Support-free printing

Drastically minimize the amount of support in a build by assigning different scanning parameters to down-skin zones based on the overhang angle. This way, users can better steer the energy input for certain overhang angles, which can avoid warpage and requires less support than the traditional single-area down-skin approach.

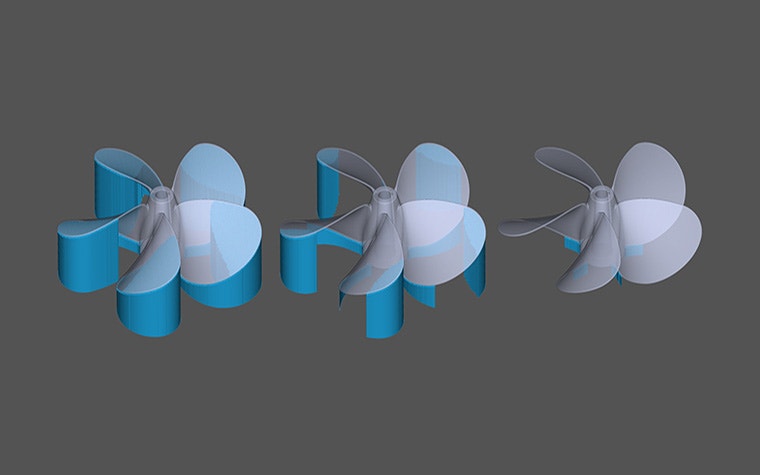

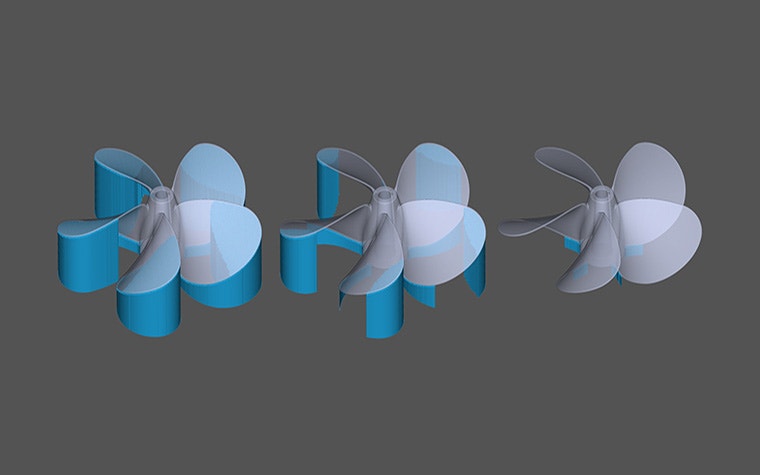

5. Load balancing (full scan field overlap)

Balance the load per laser while accounting for gas flow and fog zones to prevent interference between lasers and ensure uniform energy distribution. This can include manually assigning lasers to parts, automatically assigning lasers to parts to prevent cut vectors within a part and boost quality, automatically assigning multiple lasers to one part to drive productivity, or any combination of the three.

6. Vector splitting (partial scan field overlap)

During powder bed fusion, the 3D printer’s laser or electron beam scans the part geometry across the build platform. However, the scan field is often limited, requiring users to split parts into multiple sections that can be processed individually.

This is where vector splitting comes into play. When a part exceeds the maximum scan field overlap area, its geometry is automatically split into multiple pieces to be printed separately. And it does not simply divide the part along a fixed partition line. Instead, it intelligently determines the optimal cutting positions for vectors within the overlapping scan field regions, ensuring a seamless division and minimizing potential defects or discontinuities in the final print.

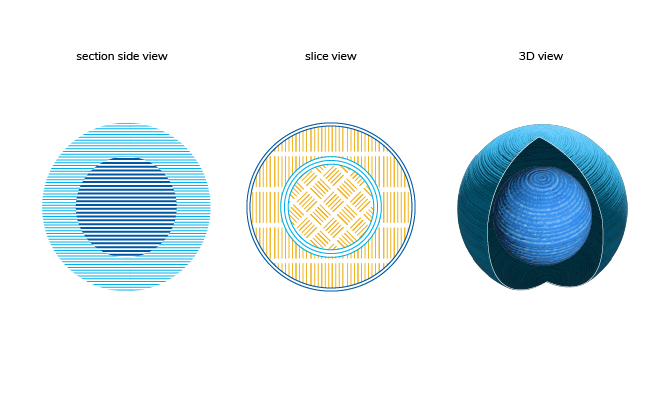

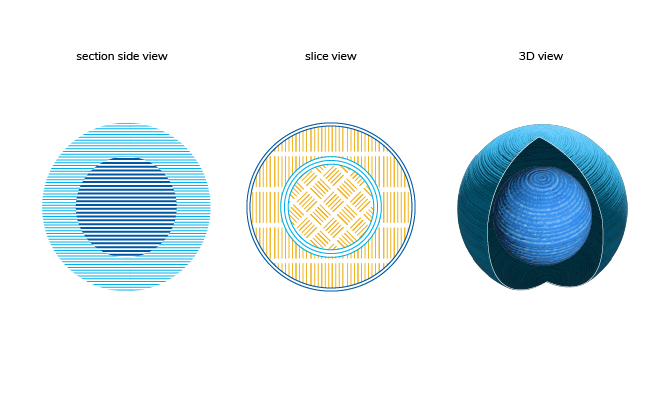

7. Hull and core

It’s also possible to divide the part into the hull and core and apply different scan strategies to improve the productivity and surface quality of the part. The core can be built with thicker slices and larger laser beams, greatly optimizing print speed. Meanwhile, the hull can use thinner slices for ideal surface quality.

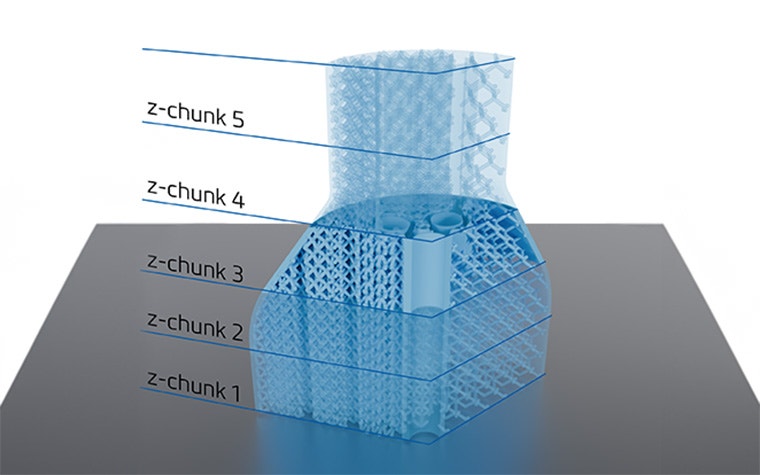

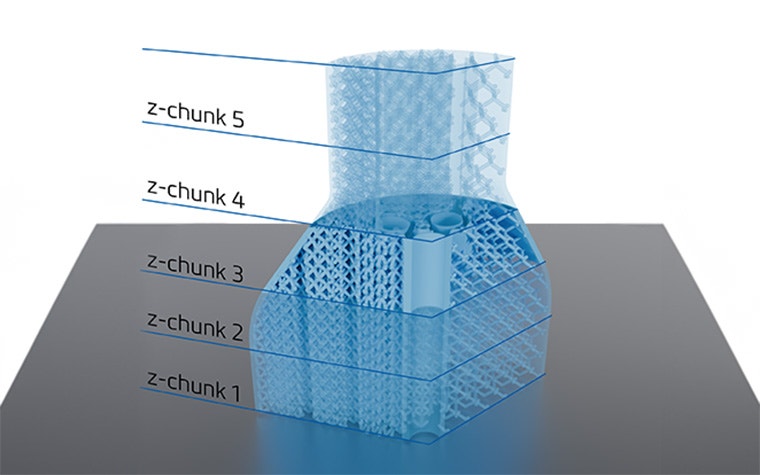

8. Z-chunking

As mentioned earlier, handling large, complex 3D models can pose a significant challenge because of computers’ memory constraints. To address this issue, Z-chunking divides the build platform into discrete vertical (Z-axis) sections, or “chunks.” Rather than processing the entire model at once, the software can process each chunk individually, reducing the necessary memory footprint. The size of the chunks is also adjustable, allowing users to balance processing speed and memory consumption.

9. Scan time estimation

Build Processors also provide accurate build time estimations with detailed time calculations of each individual layer, including laser power and scanning speed, hatch spacing and overlap, contour and infill parameters, and support structure requirements.

Accessing this precise estimation is invaluable for production planning, scheduling, and quoting. Manufacturers can provide customers with reliable lead times, optimize machine use, and efficiently execute AM workflows.

5 ways to boost production quality

In addition to productivity, improved part quality is another target many manufacturers strive for. Here are five tried-and-true ways manufacturers advance quality in AM productions.

1. Slicing

A key step in any 3D printing workflow, our slicing technology is the result of 30 years of extensive research and advancements in the field. One key feature is its ability to identify and automatically repair minor imperfections or defects in the input 3D data. The slicer also offers a comprehensive collection of configurable settings for slice optimization. Fine-tune parameters like layer height, contour optimization, and infill strategies for the perfect balance between print speed, part strength, and surface finish.

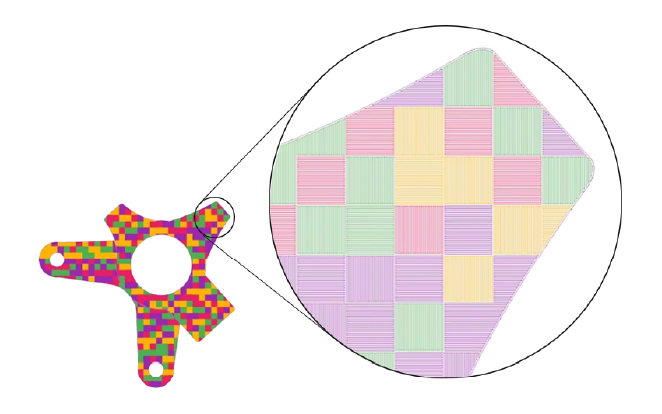

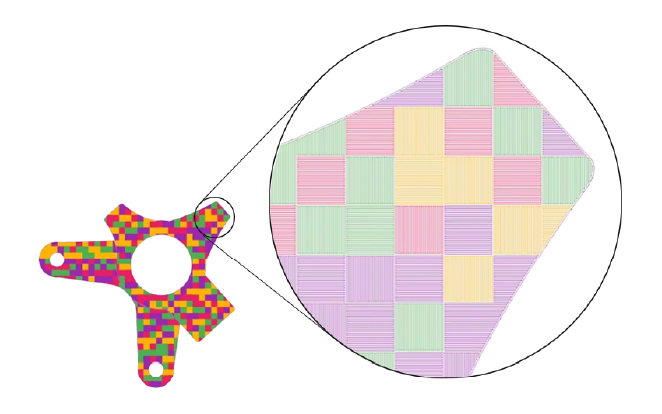

2. Zoning

Advanced zoning capabilities assign strategies to different regions, optimizing the energy deposition for an improved surface finish. Users can also visualize and analyze the different zones, including the up-skin, where the powder is directly on top; the down-skin, where powder is situated below the part, which can impact surface quality; the in-skin solidified material within the layer; and the support structures. For example, the goal with upward-facing surfaces is to reduce the appearance of visible scan patterns by rescanning and remelting the area multiple times.

3. Hatch filling patterns

Optimizing hatch filling with chess, stripes, and offset patterns enhances stress distribution and balances productivity speed. Chess patterns maintain consistent vector lengths for better temperature gradients and to manage residual stresses but sacrifice some printing speed. On the other hand, the stripe pattern strikes a middle ground, offering improved productivity over chess while still providing reasonable stress control. Offset patterns further increase printing speeds while staggering hatch vectors to distribute heat and stresses more evenly.

These customizable strategies offer the flexibility to tailor the build process according to priorities, whether that’s maximizing part quality or build speed.

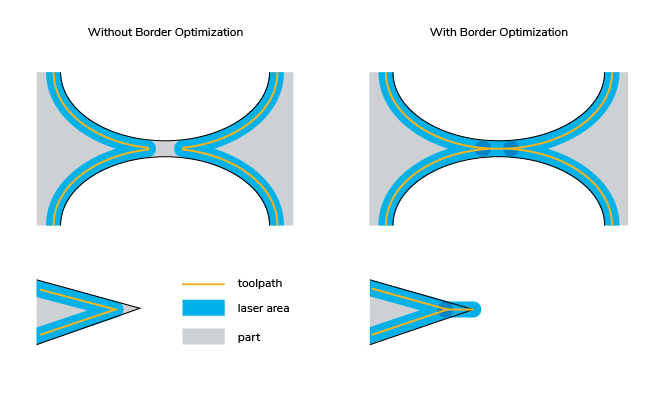

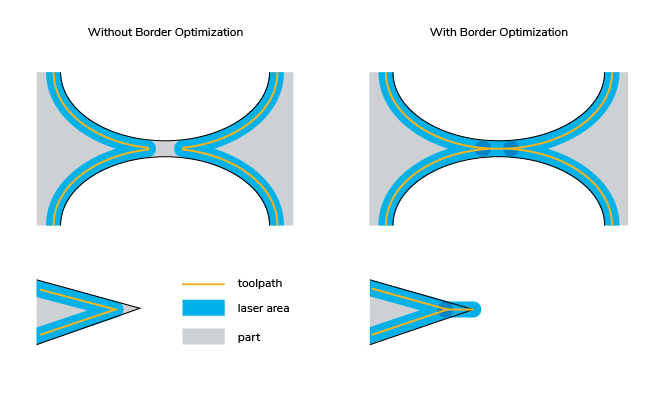

4. Border optimization

Border optimization detects and addresses specific problem areas in the part geometry to improve dimensional accuracy and overall print quality. It identifies sharp edges, thin walls, and areas lacking toolpaths, then applies tailored laser parameters to create supplementary toolpaths in these critical zones. This targeted optimization helps compensate for issues like unscanned “blocked paths” and excessive heating, ensuring tight dimensional tolerances and a high-quality final part, even with complex geometries.

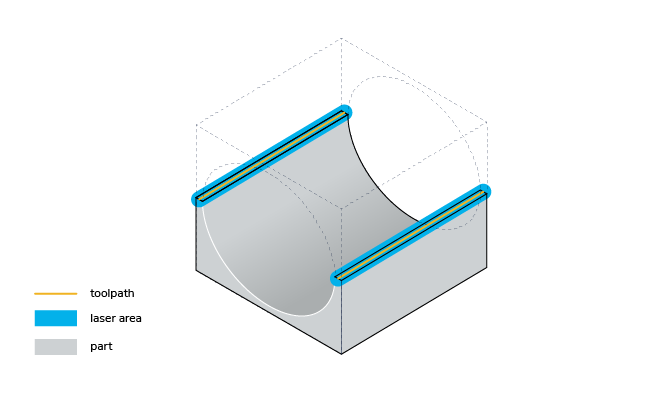

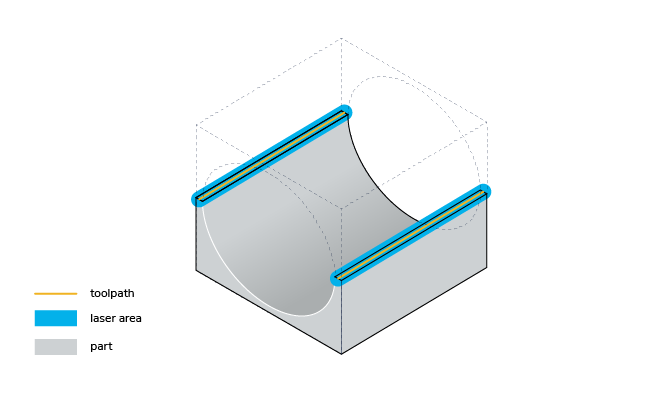

5. Thin wall detection

This function goes beyond just the border regions. With this, users can identify thin wall areas within the part geometry and apply specialized build strategies to optimize the heat distribution, such as beam compensation and block paths. Build Processors recognize that thin geometries can lead to overheating if the same parameters are applied uniformly throughout the build. This can negatively impact the quality and dimensional accuracy, so the slicer detects these regions and assigns different laser parameters or scanning strategies.

“Working with Materialise, we’ve made a giant leap in developing a high-performing Build Processor,” says Nicolas Lemaire, Product Manager of Software, Product Control, and Strategic Partnerships at Nikon SLM. “With this next generation of Build Processors, our customers using Materialise software will save time during the print job setup and profit from tools to optimize their print process.”

To keep pace with the developments in 3D printers, manufacturers need to reassess the software they use and get every drop of productivity out of their machines. Our Next-Gen Build Processors are there to help users unlock unprecedented levels of control and customization.

Get in touch to see which Build Processor development path is right for you. Our Professional Services team can also take your requirements and translate them into the right Build Processor for you. Otherwise, you can use our BP SDK to configure it yourself, maintaining full control over your own IP and development schedule.

Share on:

You might also like

Never miss a story like this. Get curated content delivered straight to your inbox.