PRESS RELEASE

Materialise and nTop Partner to Push the Boundaries of What’s Possible with Additive Manufacturing

June 24, 2024

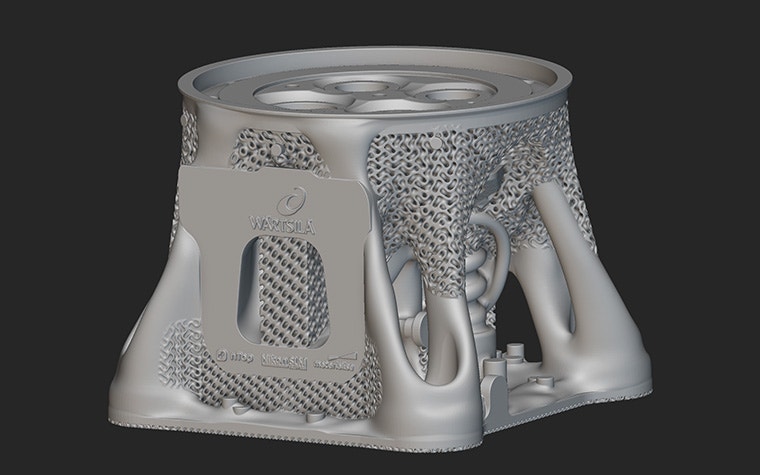

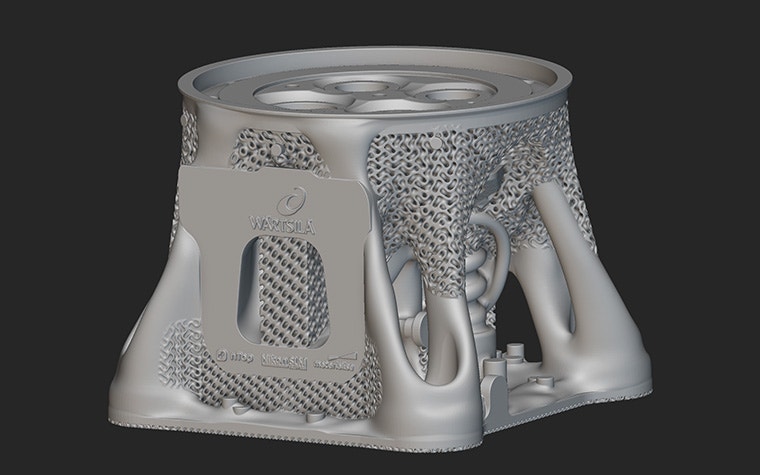

Collaboration yields high-performance 3D-printed cylinder head for Wärtsilä with enhanced cooling and 60% weight reduction

Los Angeles (CA) — June 24, 2024 — Materialise and nTop have announced a pioneering collaboration to push the boundaries of what’s possible with additive manufacturing (AM). The integration of nTop Core, nTop’s implicit modeling API, with Materialise's Magics 3D Print Suite and NxG Build Processor, will allow manufacturers to accelerate the entire design-to-manufacturing process and enable the production of complex parts that were previously impossible to print. This collaboration has already demonstrated success in producing a high-performance, 3D-printed cylinder head for Wärtsilä, significantly enhancing cooling performance and reducing weight by 60%, which was printed by Nikon SLM Solutions.

This partnership solves a common problem for complex, high-performance designs by enabling implicit design files to be exchanged between design and manufacturing teams and natively processed for production without meshing or other intermediate processes. In turn, this allows engineering teams to design higher-performance parts with more features and capabilities while assuring they can be produced precisely and economically.

nTop has developed a powerful new implicit modeling kernel and corresponding file format that can characterize highly complex, high-performance geometries at a fraction of the size of traditional CAD or mesh-based files. Until now, high-performance product designs created in nTop could not be natively processed by Magics, requiring time-consuming translations for build preparation and production. Materialise’s NxG Build Processor is configurable software that translates large and complex 3D design files into 3D printable instructions, optimizing and managing the 3D printing process from start to finish. By integrating nTop’s design software with Materialise’s Magics and NxG Build Processor, these designs can be easily transferred natively to Materialise Magics for fast, high-quality build preparation and slicing.

3D printing the impossible: innovative 3D-printed cylinder head for Wärtsilä

Materialise and nTop collaborated with Nikon SLM to produce a high-performance cylinder head for Wärtsilä, a global leader in innovative technologies and lifecycle solutions in the marine and energy markets. On its journey to enable carbon-neutral shipping and energy production, Wärtsilä explored innovative designs to optimize the cooling performance of the cylinder head, achieving a 60% weight reduction compared to the original design. This new design also allowed the integration of up to ten subsystems into the final component, reducing assembly complexity and improving cooling performance. Previously, the design complexity and file size of this innovative design made it impossible to 3D print the part using conventional large-scale AM technologies. However, by combining nTop’s design software with Materialise’s Magics and NxG Build Processor, based on implicit modeling, it became possible to 3D print the part. The final design was printed in Inconel 718 by Nikon SLM, using the largest metal printer on the market.

Meeting the challenges of printing larger and more complex parts

In response to rising customer demand for printing larger and more complex parts, machine builders have made substantial investments in developing larger printers with expanded print volumes and increased laser capacity. However, when working with complex geometries and larger build sizes, the pre-processing of slice files can be lengthy, sometimes taking days. This extended processing time increases the risk of system crashes, and the large file sizes associated with high-performance designs make it harder to move models between applications for design and build preparation, and the machines that will print them.

Despite significant progress in expanding design capabilities, the challenges in processing and manufacturing have constrained designs, limiting the functionality and performance of 3D-printed parts. The collaboration between Materialise and nTop aims to overcome these limitations by providing an integrated solution to streamline the processing of intricate and large design files, thereby unlocking new levels of efficiency and innovation in 3D printing.

"At Materialise, we understand that the future of additive manufacturing hinges on the ability to efficiently process highly complex files for high-performance parts,” said Udo Eberlein, Vice President of Software at Materialise. “If our industry cannot keep pace with the growing demands for intricate designs and larger build sizes, it becomes impossible to unlock the full potential of new AM applications. Our collaboration with nTop represents a significant step forward in breaking these barriers. By combining nTop's implicit modeling kernel with Magics and our Next Gen Build Processor, we are enabling faster, more reliable design-to-manufacture workflows, paving the way for innovations that were once deemed impossible."

“At nTop, we are committed to advancing the power of computational design to production — which is why I’m so excited about our partnership with Materialise and integration of nTop implicit models into Magics for manufacturing,” said Bradley Rothenberg, Co-Founder and CEO of nTop. “This enables our mutual customers to streamline the manufacturing of their most complex designs.”

Early Access Program for enhanced additive manufacturing workflows

Materialise and nTop have launched an Early Access Program to accelerate the adoption of high-performance geometries in additive manufacturing. Aimed at users pushing the boundaries of this technology, the program allows participants to tackle challenges, helping them enhance design-to-manufacturing workflows and overall performance. Phase 1, starting in Q3 2024, will invite 10 companies, with an additional 20 companies joining in Q1 2025. Participants will benefit from faster, higher-quality build preparation by integrating nTop’s implicit modeling API within the Materialise Magics 3D Print Suite, eliminating time-consuming implicit-to-mesh conversions and streamlining the additive manufacturing process.

"Nikon SLM Solutions is excited to be the first early access partner for the new Materialise Build Processor that natively prepares builds for our NXG XII 600 directly from nTop,” said Nicolas Lemaire, Software Product Manager at Nikon SLM Solutions. “While Nikon SLM focuses on making the NXG XII 600 the most productive AM solution with a build rate of 1000 ccm/hr, we are evaluating how the integration between nTop and Materialise can streamline the design-to-production process.”

More information about the Early Access Program is available here: https://www.ntop.com/materialise-eap/

About Materialise

Materialise incorporates more than three decades of 3D printing experience into a range of software solutions and 3D printing services that empower sustainable 3D printing applications. Our open, secure, and flexible end-to-end solutions enable industrial manufacturing and mass personalization in various industries — including healthcare, automotive, aerospace, eyewear, art and design, wearables, and consumer goods. Headquartered in Belgium and with branches worldwide, Materialise combines the largest group of software developers in the industry with one of the world's largest and most complete 3D printing facilities

About nTop

nTop is the leading platform for designing and developing high-performance product designs quickly and efficiently. By using data to automate design exploration and optimization, nTop empowers customers to get dramatically better products to market quickly. nTop seamlessly fits into established workflows and integrates with existing design, analysis, and simulation tools, making it easy to share design knowledge, accelerate iteration, and drive innovation faster than ever before. For more information, visit ntop.com.

Materialise press contact

nTop press contact

Sheila Seles

Email: press@ntop.com

Share on: