Architecture

From mind to model: let us bring your ideas to life

A picture is worth a thousand words. A 3D model is worth a thousand pictures. You can count on Materialise’s wide range of technologies and materials and a suite of specialized software to make creating your models easy and affordable. Bring your architectural designs to life in incredible detail, right down to the doors and windows.

Why choose 3D printing?

Showcase your vision

Take your design from the page to the stage with a true-to-life visualization of your blueprints. With 3D printing, you can include even the finest details, helping you share your ideas and get your projects moving.

Save time and money

With additive manufacturing, building models is quick, easy, light on labor, and faster and more affordable than conventional techniques.

One design, many models

Accurately and reliably build multiple models from the same base design whenever the need arises using 3D printing.

Why choose Materialise Manufacturing?

Print at scale

Build models up to two meters long in a single piece with proprietary technology, Materialise’s Mammoth Stereolithography machines. Whether it’s a large individual building or an entire city, we can help you build it.

Include the fine details

Capture the finest details and realize your most intricate designs. With our 3D printing software and technology, you can produce even the smallest features such as windows, doors, and etching.

Add the finishing touch

With an extensive range of colors, finishes, and assembly options, and a dedicated team at your service, you can choose the combination that matches your vision and finish the job in style.

Get it right first time

Shorten lead times, save money, and reduce waste by working with an in-house team of Design & Engineering experts to prepare and optimize your files before you print.

Ideal materials for architectural models

ABS

Technology

Fused deposition modeling

Description

Known for its toughness, durability, and affordability, ABS is one of the most widely used industrial thermoplastics. It is suitable for prototyping, tooling, and end-use parts.

Key characteristics

- Tough, durable material

- High impact strength

- Up to 80% of the strength of injection-molded ABS

- Fast Lane service available for online orders of ABS White/Black – Normal finish

- Max part dimensions: 300 x 300 x 300 mm

- Max part dimensions (Fast Lane orders): 250 x 250 x 300 mm

PA 12 (SLS)

Technology

Selective laser sintering

Description

PA 12 (SLS) is a general-purpose material that offers excellent long-term stability and good chemical resistance, making it suitable for functional prototypes and end-use parts, as well as consumer goods.

Key characteristics

- Strong, general-purpose material printed without a support structure

- High strength and stiffness

- High chemical, mechanical, and thermal resistance

- Fast Lane service available for online orders of PA 12 (SLS) – Normal finish

- Max part dimensions: 630 x 330 x 550 mm

- Max part dimensions (Fast Lane orders): 270 x 270 x 270 mm

TuskXC2700W

Technology

Stereolithography

Description

Designed to simulate ABS, TuskXC2700W is a strong material with a rapid lead time. It is ideal for water-resistant and functional prototypes. Also available in clear.

Key characteristics

- Strong, water-resistant material with properties similar to ABS and PBT

- Fast Lane service available for online orders of TuskXC2700W – Basic finish, Support marks removed, or Support marks removed + sandblasted

- Max part dimensions: 350 x 350 x 350 mm

- Max part dimensions (Fast Lane orders): 100 x 100 x 100 mm

ProtoGen White

Technology

Stereolithography

Description

ProtoGen White's resilience, surface quality, and thermal properties make it suitable for general-purpose applications such as RTV molding patterns, highly detailed parts, and durable concept models.

Key characteristics

- Similar properties to ABS

- Resilient material with good surface quality

- Among the largest printing volumes of stereolithography materials

- Max part dimensions: 2,000 x 700 x 788 mm

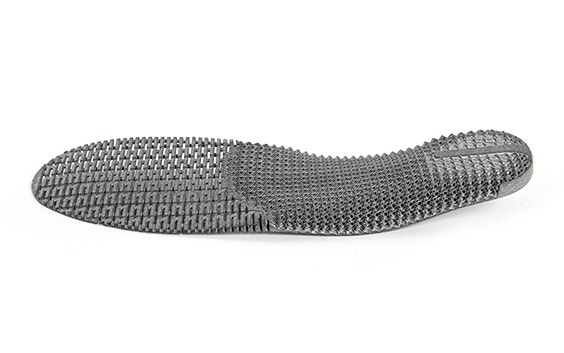

PA 12 (MJF)

Technology

Multi Jet Fusion

Description

With higher density and lower porosity than laser-sintered polyamide, this strong, general-purpose material is ideal for precision forms and works equally well for functional prototypes or end-use parts.

Key characteristics

- Strong, general-purpose material printed without a support structure

- High density and low porosity, with crisp textures and detailed surfaces

- Near-isotropic mechanical properties

- Max part dimensions: 370 x 274 x 375 mm

Typical uses of 3D printing in architecture

Architectural models

Houses, apartment blocks, city halls — 3D printing brings them all to life quickly and affordably, complete with small and complex details. It’s ideal for helping investors share your vision.

Planning cityscapes

Planning entire cities with 3D printing is considerably more efficient than conventional techniques. Individual streets, trees, parks, and roundabouts can be included, with even the finest details printed accurately and consistently.

Complex structures

Some aspects of buildings, such as arches and domes, are often difficult to model by hand. 3D printing makes it simple, even for more complex infrastructure such as bridges and flyovers.

Our products and services for architecture

Ready to start your project with us? Discover our solutions, ideal for your industry.

Transform your product development cycle and get the best possible products to market faster. Get unbiased advice and dedicated support from teams committed to your success.

Build your success on a platform of software tools that efficiently manage and control the 3D printing process, allowing you to meet the highest standards of the most demanding industries.

Get direct 24/7 access to the technologies and materials you need to bring your designs to life. Instant quotes, short lead-times, and easy checkout.

利用行业领先的数据和构建准备软件,提高生产效率,自动执行重复性任务,优化印刷成功率。

Inspiration

Get inspired for your next project with a look at how 3D printing has made its mark in the world of architecture.

Other industries we work in

Navigate the future of aerospace with shorter lead times, more affordable small series production, and the unrivaled design freedom that additive manufacturing can offer.

From quick, performant prototypes and visual models to small series manufacturing and automotive tooling, tick every box by bringing 3D printing into existing or new production workflows.

Enter a new era of more sustainable, on-demand manufacturing where creativity and innovation have no boundaries and where quick time-to-market, and zero stock-risk, boost business agility.