Material

ABS

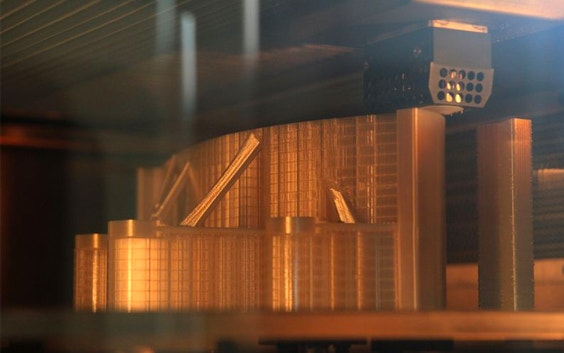

Known for its toughness, durability, and affordability, ABS is one of the most widely used thermoplastics in injection molding and is used for applications such as automotive components and LEGO bricks. Printed ABS has up to 80% of the strength of injection-molded ABS, making it highly suitable for concept modeling, form-, fit-, and function testing, tooling, and end-use parts.

Technical specifications

| Maximum part dimensions | 300 x 300 x 300 mm 250 x 250 x 300 mm (Fast Lane orders) |

| Standard accuracy | ±0.15% (with a lower limit of ±0.2 mm) |

| Layer thickness | 0.25 mm |

| Minimum wall thickness | 1 mm |

| Minimum detail size | 0.3 mm |

| Interlocking or moving parts | Yes |

| Internal channels | Yes |

| Surface structure | Rough surface with visible layers; less definition than our other ABS materials |

Datasheet

| PARAMETER | VALUE | UNIT | METHOD |

| - | 1.05 | g/cm³ | |

| ASTM D638 | 22 | MPa | |

| ASTM D638 | 1,625 | MPa | |

| ASTM D790 | 41 | MPa | |

| ASTM D790 | 1,834 | MPa | |

| ASTM D256 (Notched, Izod) | 107 | J/m | |

| ASTM D638 | 6 | % | |

| ASTM D648 (@1.82 MPa) | 76 | °C | |

| DSC (SSYS) | 108 | °C |

Actual values may vary with build conditions and in relation to the part’s geometry and orientation.

Please get in touch with our team for more information and guidance.

Finishing degrees

The right finish can transform your print into a product. Explore the post-production finishes we offer for this material. If you have any questions or special requests, get in touch with us.

Train and learn

Get more from your next project with helpful resources dedicated to ABS and fused deposition modeling.