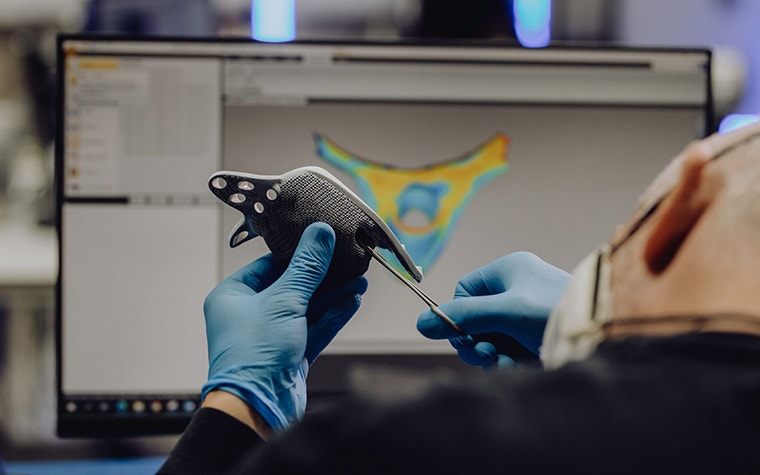

A Stringent Approach to Quality

Your project is in safe hands

At Materialise, quality comes first. With certifications such as ISO 9001, ISO 13485, and EN9100, as well as strict quality assurance processes and dedicated procedures for prototyping and manufacturing, you can trust that every product you get is exactly what you ordered. Discover why you can rely on our approach to quality assurance and control.

Quality assurance

Industry-specific certifications

We produce every part in accordance with our ISO 9001-certified quality management system and industry-specific certifications such as ISO 13485 and EN9100.

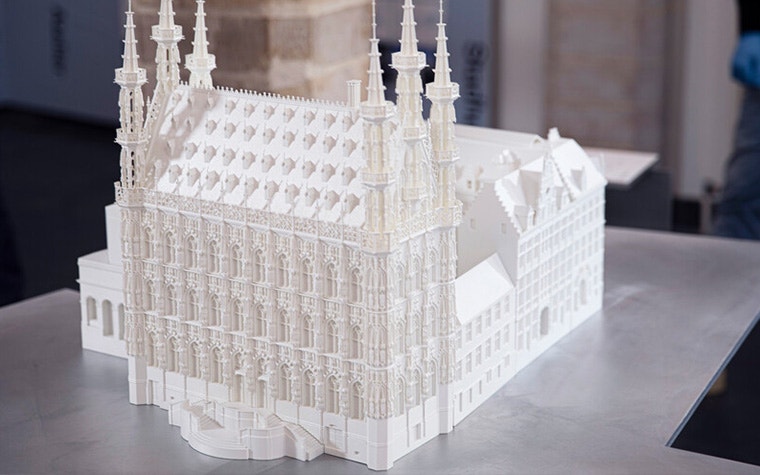

More than 30 years of AM experience

Our in-depth knowledge of AM part production and requirements is the backbone of our dedicated processes and controls for prototyping and manufacturing.

Two unique services to meet your needs

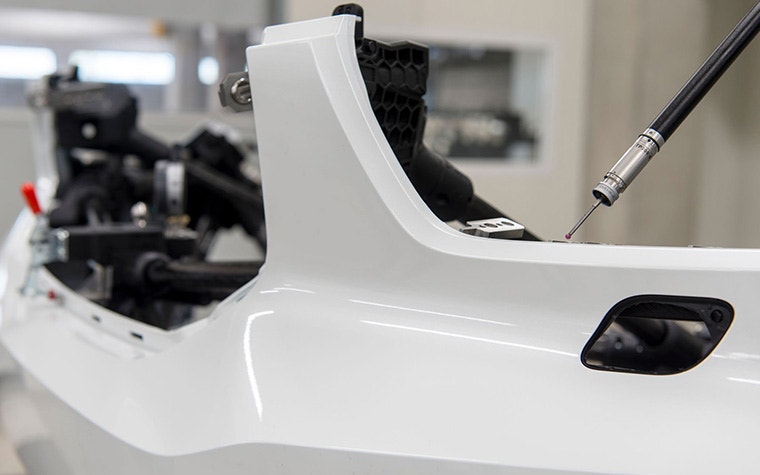

High-quality prototyping

All prototypes produced at Materialise follow our standard quality parameters for dimensional accuracy and cosmetic appearance.

- We conduct a basic visual inspection of surface quality against Materialise quality inspection guidelines

- Tolerances are guaranteed with a standard accuracy of ±0.3% on bounding box (X-Y-Z) dimensions

Consistent, repeatable, reliable series production

With our manufacturing services for series parts, we have developed extensive quality and process controls to ensure that parts are consistently produced from part 1 to part 10,000 and beyond.

- Our proven NPI process successfully carries your idea from concept to scaled production.

- Diligent quality, change, and process controls ensure the repeatability you need to scale up to series production.

Prototyping quality control

Visual inspection

Our quality inspection guidelines cover any issues that arise in the following stages:

- Data prep

- Labeling

- Printing

- Finishing

Tolerances

We guarantee that every part we deliver will be printed with a standard accuracy of ±0.3% across the X, Y, and Z axes. We can also provide a limited dimensional inspection report for every project upon request.

Manufacturing quality assurance

Process and change control

We’re experienced with different levels of process qualification, with strict process and change control. We’ll inform you about any changes that may affect the form, fit, or function of your parts.

- Process validation (IQ, OQ, PQ)

- Process Flow Charts, PFMEAs, Control Plans

- Process Control Documents

- Process capability charts based on process control data

- Weekly change control board

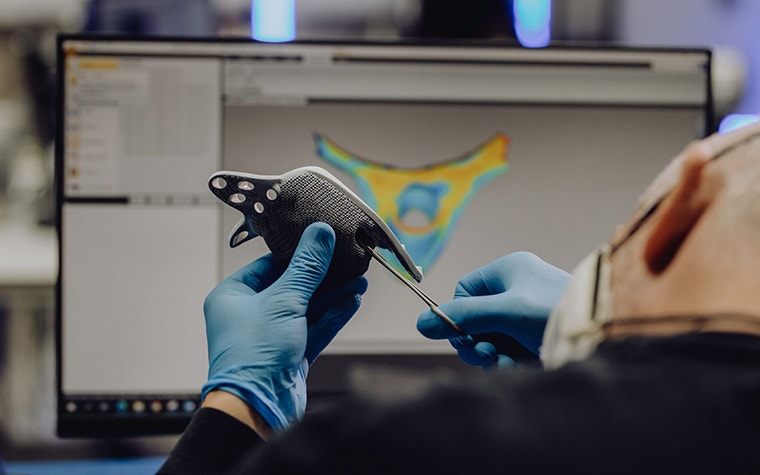

Quality control

We know that printing one part in a series of 100 is very different from printing one part 100 times. Our stringent quality controls ensure the repeatability and consistency you need in every order.

- Visual inspection aligned with quality catalog

- Dimension control, including SPC sampling

- Weight measurement

- Surface roughness measurement

- Tensile testing acc. to ISO 527-1

Capabilities

Our 3D printing facilities include a number of dedicated production lines and other additions that are essential for various industries.

- Production services, including drilling, reaming, inserts, threading, and clean room packaging

- 3D scanning

- Bagging and tagging

- Design and Engineering services