技術

Vacuum Casting

Vacuum casting is a fast and cost-effective copying technique for producing high-quality plastic parts that are comparable to injection-molded components. Using two-component polyurethanes and silicone molds created from a 3D-printed master, this technique is especially suitable for fit and function testing, marketing purposes, or short series of end-use parts.

Why work with Materialise Manufacturing?

At Materialise, we can help you make a big impact with small series production. Our range of 26 carefully selected rubber-like, ABS-like, and PP-like polyurethanes provides an outstanding variety of properties. What's more, if you're looking for a specific finish, the teams at our dedicated vacuum casting center can match the exact finish you need for your parts.

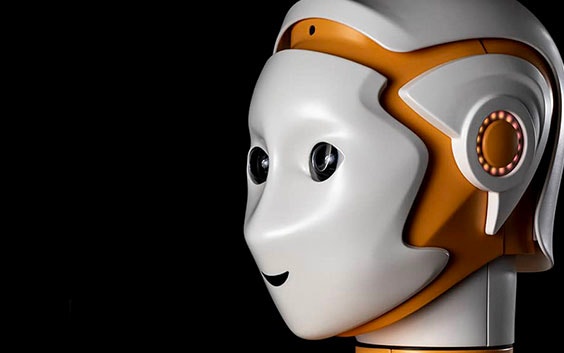

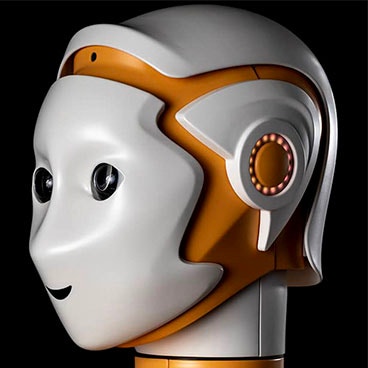

Discover applications of vacuum casting

技術仕様

| Maximum build dimensions | The size of the mold is limited by the dimensions of the vacuum chamber (1,900 x 900 x 750 mm) and by the volume of the product (maximum volume: 10 liters) |

| Standard accuracy | ±0.3% (with a lower limit on ±0.3 mm on dimensions smaller than 100 mm) |

| Minimum wall thickness | At least 0.75 mm to ensure the mold is filled properly; for best results, wall thickness of at least 1.5 mm is recommended |

| Surface structure | High-quality surface finish comparable to injection molding |

Materials

Choose from a broad selection of materials when you come to Materialise for your vacuum casting projects.

Rubber-like Polyurethanes

技術

Vacuum casting

詳細

Offering a range of different material properties, our rubber-like polyurethanes can be used with silicone molds to produce high-quality prototypes or small series of end-use parts.

主な特徴

- Excellent surface quality and detail, resembling TPE, TPU, and silicone rubber

- Ideal for applications that need good shock absorption

- Cost-effective way to produce prototypes or small series of end-use parts

- Max part dimensions: 1,900 x 900 x 750 mm (maximum part volume: 10 liters)

ABS-like Polyurethanes

技術

Vacuum casting

詳細

Offering a range of different material properties, our ABS-like polyurethanes can be used with silicone molds to produce high-quality prototypes or small series of end-use parts.

主な特徴

- Excellent surface and detail, with injection-molded look and feel

- Flame-retardant, food-safe, and UV-stable materials available

- Cost-effective way to produce prototypes or small series of end-use parts

- Max part dimensions: 1,900 x 900 x 750 mm (maximum part volume: 10 liters)

PE/PP-like Polyurethanes

技術

Vacuum casting

詳細

Offering a range of different material properties, our PE/PP-like polyurethanes can be used with silicone molds to produce high-quality prototypes or small series of end-use parts.

主な特徴

- Excellent surface and detail, with injection-molded look and feel

- Tough and lightweight with a wide range of finishes available

- Cost-effective way to produce prototypes or small series of end-use parts

- Max part dimensions: 1,900 x 900 x 750 mm (maximum part volume: 10 liters)

Work with us: discover our products and services

Want to use vacuum casting in a future project? Discover the services that can help you do it.

私たちのエキスパートとのコラボレーションで、ものづくりを革新し、スピードアップしてください。あらゆる産業、用途に対応する充実の自社技術にお任せください。

Transform your product development cycle and get the best possible products to market faster. Get unbiased advice and dedicated support from teams committed to your success.

Build your success on a platform of software tools that efficiently manage and control the 3D printing process, allowing you to meet the highest standards of the most demanding industries.

3Dプリントでお客様のビジネス課題の可能性を拡げましょう。どのアプリケーションがお客様のニーズを満たすことができるかMaterialiseのエキスパートにご相談ください。

Train and learn

Get more from your next project with helpful resources dedicated to vacuum casting.