PRESS RELEASE

Materialise Launches Integrated Mimics Platform to Accelerate Adoption of Personalized Medical Care

December 10, 2024

Unified platform enables faster collaboration, segmentation, and design

Leuven, Belgium — December 10, 2024 — Materialise, a global leader in medical 3D printing and planning solutions, has launched its fully integrated Materialise Mimics platform for enhanced efficiencies in advanced 3D planning and personalized device creation, providing accessible patient care for medical device companies and hospitals globally.

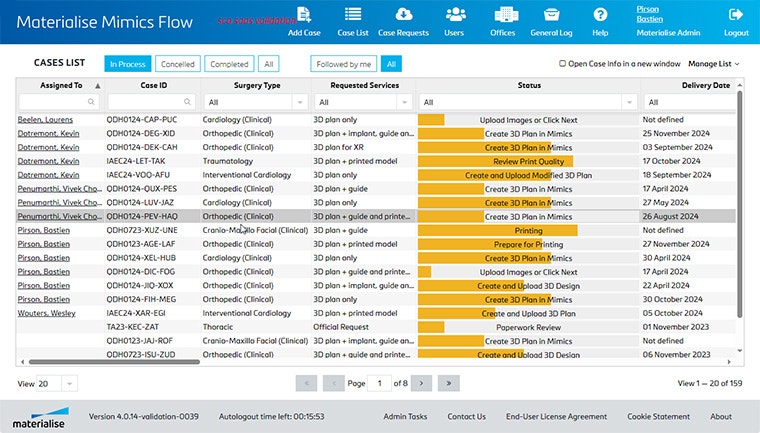

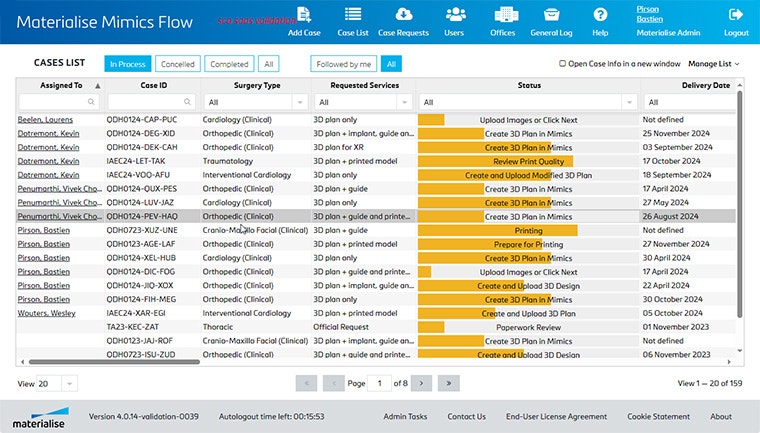

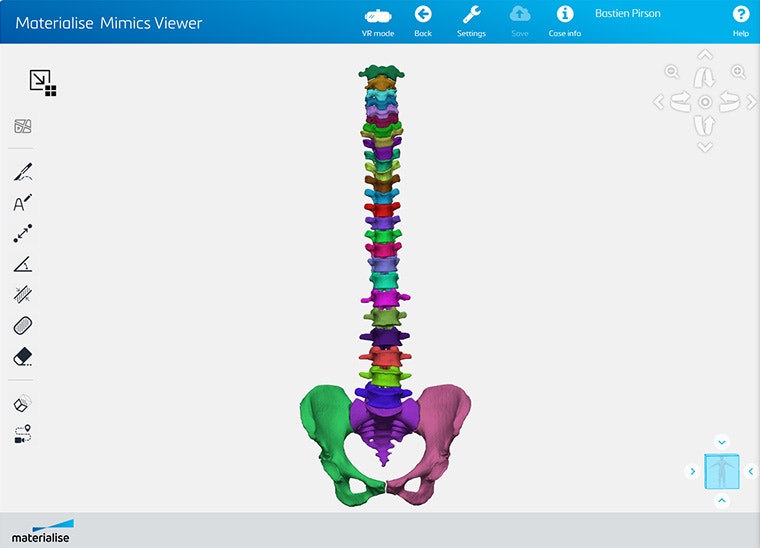

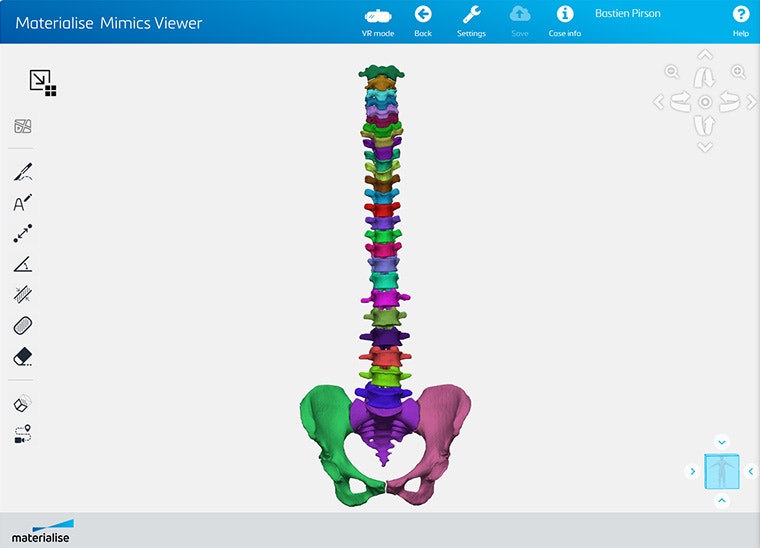

The platform leverages Materalise’s flagship medical engineering software, Mimics, which is used to create virtual and 3D-printed patient-specific anatomical models for pre-procedural planning, as well as the design of patient-specific implants and surgical guides. The new end-to-end solution provides hospitals with a single integrated platform to enable personalized patient care. What’s more, medical device companies gain access to a workflow that enables all phases of the medical device design process — from research and development through clinical trials to full scale-up and commercialization.

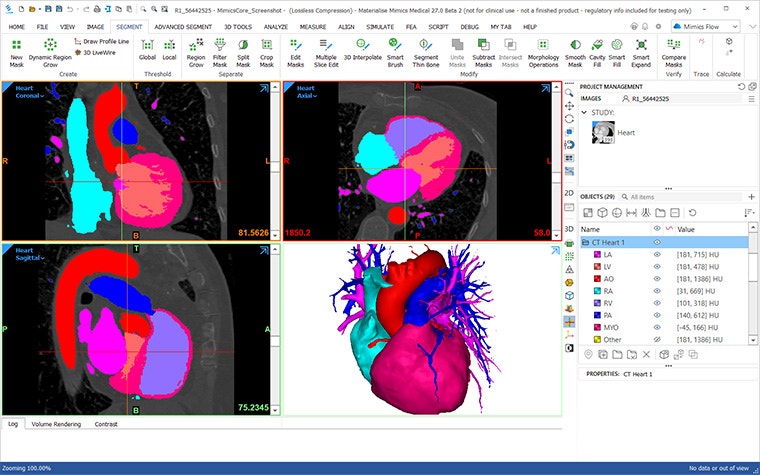

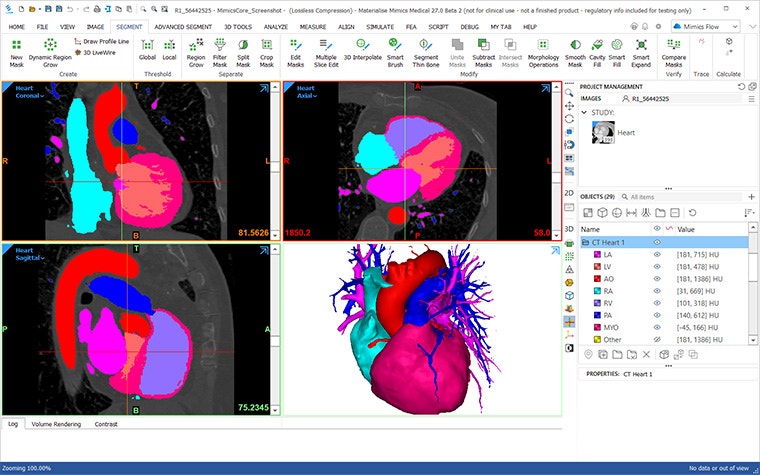

The software release incorporates Mimics software projects into a unified Mimics platform — including both desktop and cloud applications. The integration enables better collaboration, automation, and easier access to new technology, including unified case management, artificial intelligence (AI)-enabled segmentation, and visualization of surgical plans and models via augmented reality and extended reality.

“With the new, integrated Mimics platform, we are enhancing medical 3D planning and personalized device design by facilitating stronger and faster collaboration among clinicians and engineers,” said Sebastian De Boodt, Business Line Director at Materialise. “This creates opportunities for more efficient resource utilization and easier access to 3D technology, facilitating hospitals and medical device companies to sustainably deliver personalized treatment to more patients.”

Clinicians and engineers can work together to quickly, effectively, and securely plan their cases within the platform. The cloud and desktop applications sync with ease while offering advanced traceability through ongoing activity and version logs. This improvement helps quality control and to reduce lead times by enabling a patient’s medical team and their medical technology suppliers to work in files simultaneously — facilitating more efficient collaboration and communication within a digital environment. In fact, the sharing of case information can be completed in compliance with data privacy standards such as HIPAA, ISO 27001 (data security), and ISO 27701 (data privacy).

The latest version of Mimics offers improved access to AI-enabled image segmentation. Nine segmentation algorithms are now available, with enhanced capability for segmenting the torso area — including hip and lower torso segmentation. Further automating the design process, 3D modeling tools have also been improved, increasing efficiency when producing anatomical models and designing surgical guides.

“Mimics is a name radiologists and other clinicians have come to know and trust because it enables us to effectively support personalized care through 3D planning and printing,” said Frank Rybicki, MD, PhD, Chair of the Department of Radiology at Banner University Medical Center and University of Arizona College of Medicine, Phoenix. “The latest update from Materialise offers enhanced collaboration and tools, helping us to identify the best solutions for each unique case and support other clinicians in achieving optimal outcomes for our patients.”

The launch of the Mimics platform is the latest evolution in Materalise’s medical solutions. For more than 30 years, Materialise has been enabling the creation of 3D models from medical image data that are used for a variety of purposes, including pre-surgical planning, surgical guide design, and personalized implant design.

To learn more, visit What’s New in Mimics? | Product Update 2024.

About Materialise

Materialise incorporates more than three decades of 3D printing experience into a range of software solutions and 3D printing services that empower sustainable 3D printing applications. Our open, secure, and flexible end-to-end solutions enable industrial manufacturing and mass personalization in various industries — including healthcare, automotive, aerospace, eyewear, art and design, wearables, and consumer goods. Headquartered in Belgium and with branches worldwide, Materialise combines the largest group of software developers in the industry with one of the world's largest and most complete 3D printing facilities

L-104352-02

Materialise medical devices may not be available in all markets because product availability is subject to the regulatory and/or medical practices in individual markets. Please contact your Materialise representative if you have questions about the availability of Materialise Medical devices in your area.

Materialise press contact

Share on: