PRESS RELEASE

3D Technologies from Materialise Play a Pivotal Role in the World’s First Whole-Eye Transplant

November 8, 2023

3D technologies developed by the Belgian 3D printing company Materialise have played a pivotal role in the first-ever successful eye transplant. The landmark surgery, performed on May 27 at NYU Langone Health Hospital in New York, also included a partial face transplant. Materialise developed a virtual preoperative 3D plan of the surgery and 3D printed various medical devices tailored to the donor and patient, which ensured that the surgery could be performed faster and more accurately. The same instruments are increasingly used in routine operations. They provide the surgeon with an additional level of confidence, which results in improved patient outcomes.

The recipient, Aaron James of Hot Springs, Arkansas, survived a deadly 7,200-volt electric shock while working as a high-voltage lineman in June 2021, when his face accidentally touched a live wire. It is the first time ever that a complete eye has been successfully transplanted and also the first time that this is done in combination with a partial face transplant. The operation lasted 21 hours and was supported by a team of more than 140 surgeons and medical staff, including clinical engineers from Materialise.

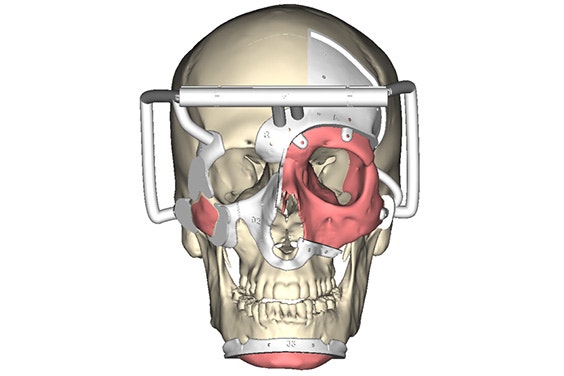

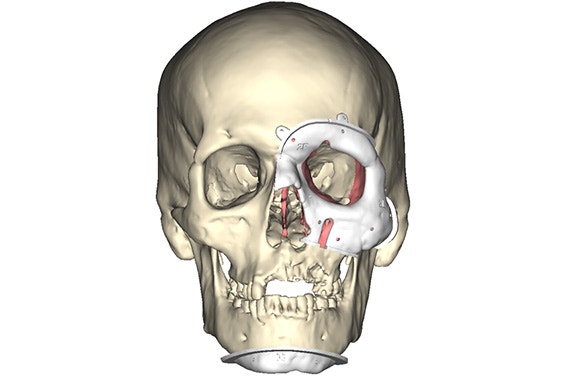

Materialise clinical engineers worked closely with the surgical team at NYU Langone Health for several months to develop a virtual plan based on CT scans. These plans enable surgeons to prepare for the surgery and visualize different scenarios. Materialise also designed and provided many cutting guides and bone models to support seven cadaver labs leading up to the surgery.

During the surgery, cutting instruments and bone models were used, which were personalized to the donor and the patient and were 3D printed by Materialise. These cutting instruments ensure that the bone fragments can be positioned faster and with extreme precision. After Materialise was notified that a suitable donor had been found and received the CT scans, it took less than 24 hours to preplan the case, design and 3D print the instruments, and for a Materialise employee to fly them to New York in time for the surgery.

Personalized surgical guides for the donor (left) and recipient (right)

The NYU Langone Health press release and a comprehensive media kit are available at https://nyulangone.org/news/nyu-langone-health-performs-worlds-first-whole-eye-partial-face-transplant

About Materialise

Materialise incorporates more than three decades of 3D printing experience into a range of software solutions and 3D printing services that empower sustainable 3D printing applications. Our open, secure, and flexible end-to-end solutions enable industrial manufacturing and mass personalization in various industries — including healthcare, automotive, aerospace, eyewear, art and design, wearables, and consumer goods. Headquartered in Belgium and with branches worldwide, Materialise combines the largest group of software developers in the industry with one of the world's largest and most complete 3D printing facilities

Materialise press contact

Share on: