CASE STUDY

Gatewing X100: Vacuum-Cast End-Use Parts Take Flight

In order to produce the X100 unmanned aerial vehicle, Gatewing uses a combination of manufacturing processes. For parts that need the extra advantages 3D printing technology can offer, Gatewing comes to Materialise.

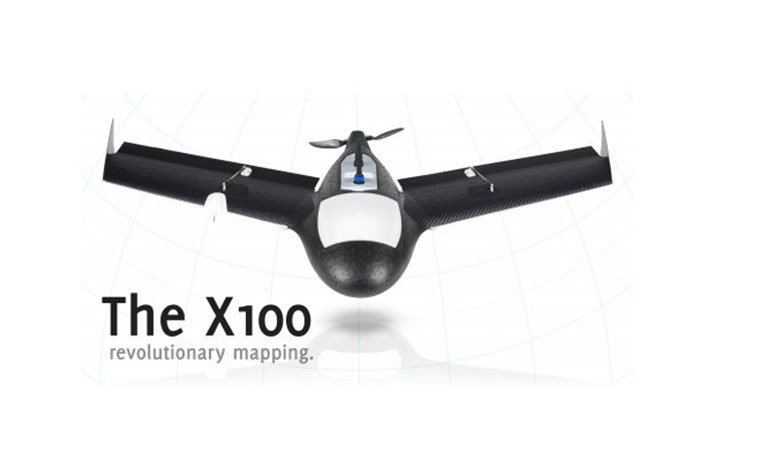

The Gatewing X100 unmanned aerial vehicle is the world’s fastest and easiest to use remote sensing solution, enabling users to collect digital images to create aerial photo maps with georeferencing. Thanks to its aerodynamic design, clever body structure, and carefully chosen materials, the X100 is ideal for day-to-day handling and intensive usage in a wide range of weather and environmental conditions.

The challenge

Cost-effective short-series production

In an industry where technology is rapidly evolving, it is important to be able to adapt quicky and deliver the latest features while still remaining competitive. Gatewing needed a solution for producing parts for its popular X100 unmanned aircraft that would allow it to easily modify designs when needed, without resorting to costly injection molding. An example of this is the craft’s camera ring, which needs to be able to hold the best camera on the market.

The solution

3D printing and vacuum casting

The process of creating end-use parts starts with 3D-printed prototypes produced using fused deposition modeling and laser sintering, a step that guarantees that the parts are ideal for the finished product. When the design is finalized, a master copy is then created using stereolithography and put into production with vacuum casting.

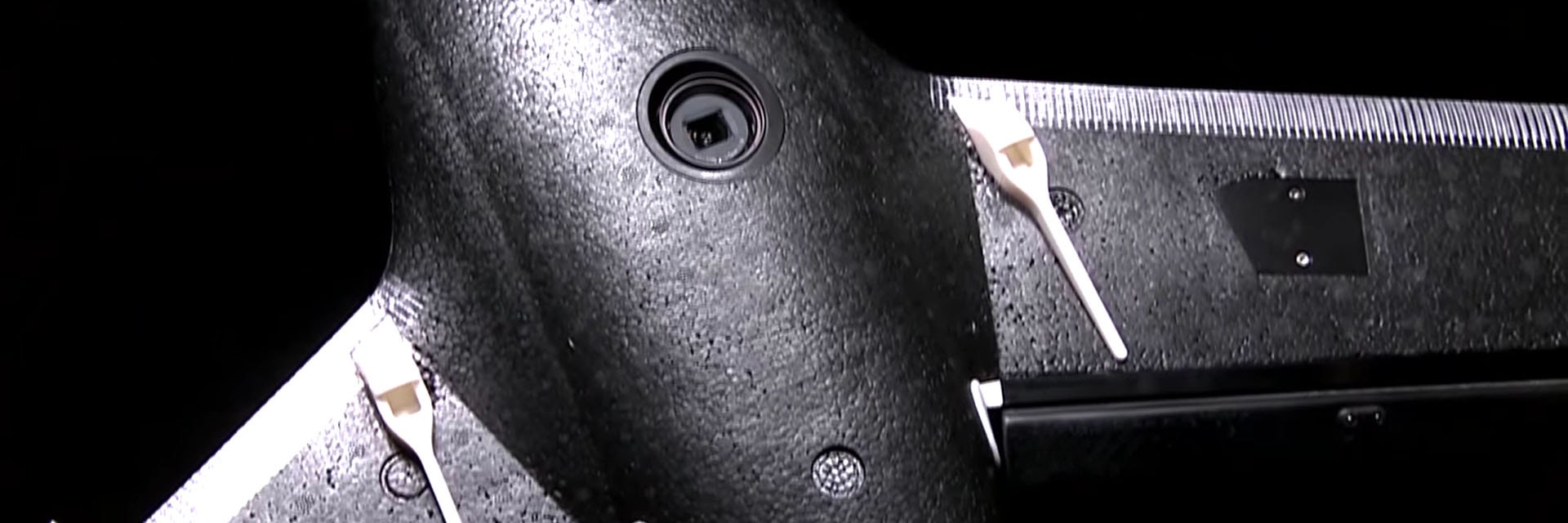

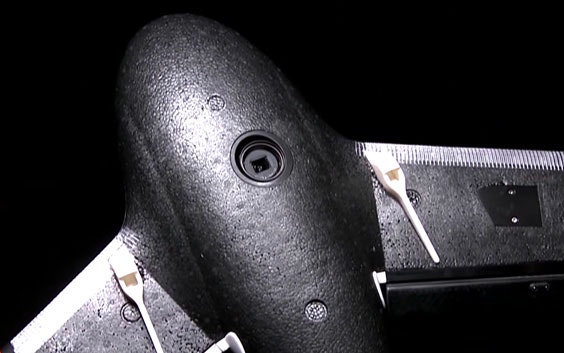

This process was undertaken for the camera ring, e-box, body cap, and frame of the X100, while for a small PA cap, both the prototypes and the final product are manufactured with laser sintering.

Where needed, a special electromagnetic resistant coating is also added to the inner side of the parts to give the electronics the extra protection that they deserve.

The result

A low-weight, high-quality frame at an attractive price

Anyone in the aerospace industry knows the incredible importance of weight when designing an aircraft. For the X100, incorporating vacuum casting into the frame (with 3D-printed PA caps ensuring that the material stays out of the carbon tubes involved) means that Gatewing can keep weight to a minimum while still achieving the strength needed.

By manufacturing the camera ring, e-box, and body cap with Materialise, as opposed to using injection molding, Gatewing can seamlessly integrate new technology into their aircraft with little extra effort or cost. The high initial investment involved in injection molding is no longer an issue when additive manufacturing and vacuum casting are used to create a finished part. In the case of the camera ring, if the latest and greatest camera does not fit into the camera ring, the digital design can be adapted to fit around the new lens and be ready for production in time for the next order to be delivered.

Furthermore, as opposed to injection molding where only great volumes bring down the price per part, at Materialise, the low initial investment allows Gatewing to get the best part at the best price whether it is an order for 1 part or 1,000 parts. Combined with the ability to adapt the design as needed, this allows Gatewing to meet the growing demand for their aircraft, integrate the latest technology, and still offer the X100 at an attractive price.

Share on:

This case study in a few words

Aerospace

Stereolithography

Fused deposition modeling

Selective laser sintering

Vacuum casting

PA 12

Weight reduction

Cost reduction

Affordable short-series production