CASE STUDY

OSSTEM IMPLANT Brings Dental Care to the Next Level

Today, human beings live longer than ever before. With a growing elderly population, healthcare, including dental care, has become increasingly important. OSSTEM IMPLANT, a leading dental implant manufacturer, has introduced 3D printing technology into their workflow. Powered by Materialise Magics software, they offer patients the highest quality and most innovative dental implant products.

Improving customer service with 3D-printed dental implants

OSSTEM IMPLANT is a global leader in providing dental implants, bio material and medical devices, with 23 local offices and 56 distributors in Asia, the USA and Europe. Their market share is the fifth biggest worldwide.

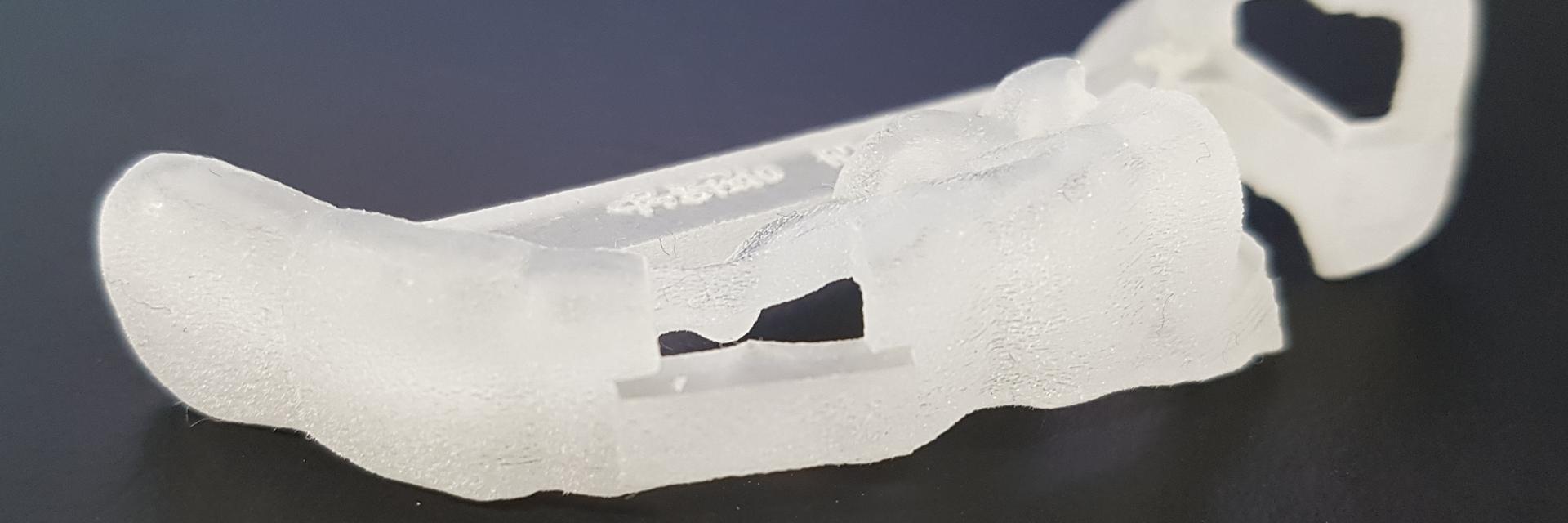

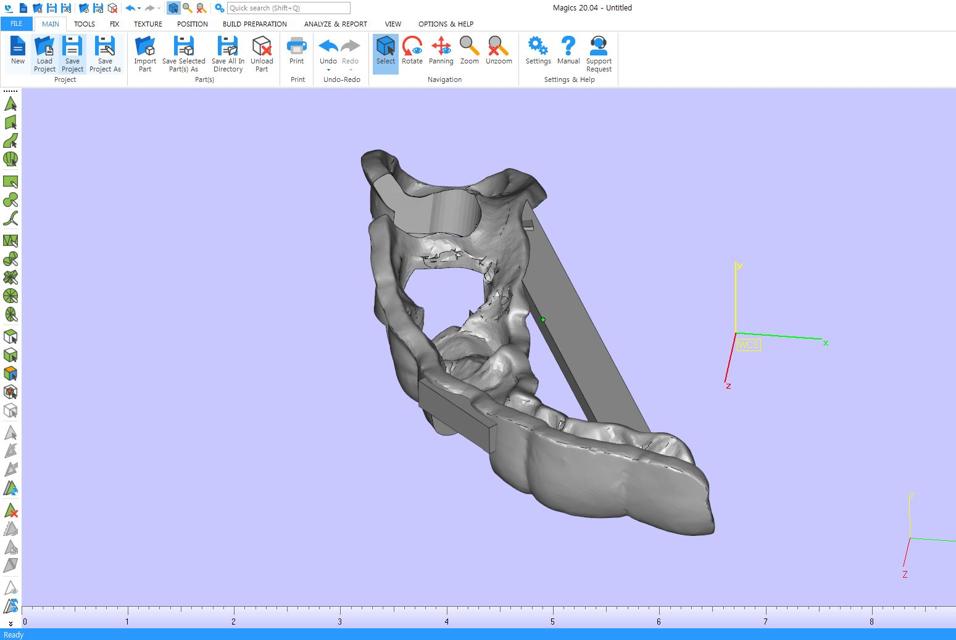

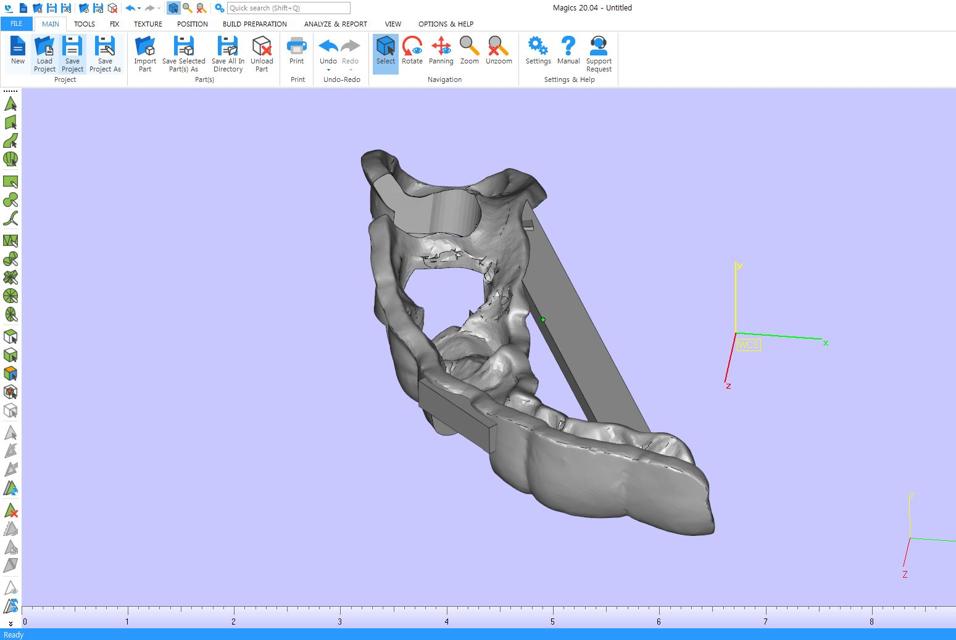

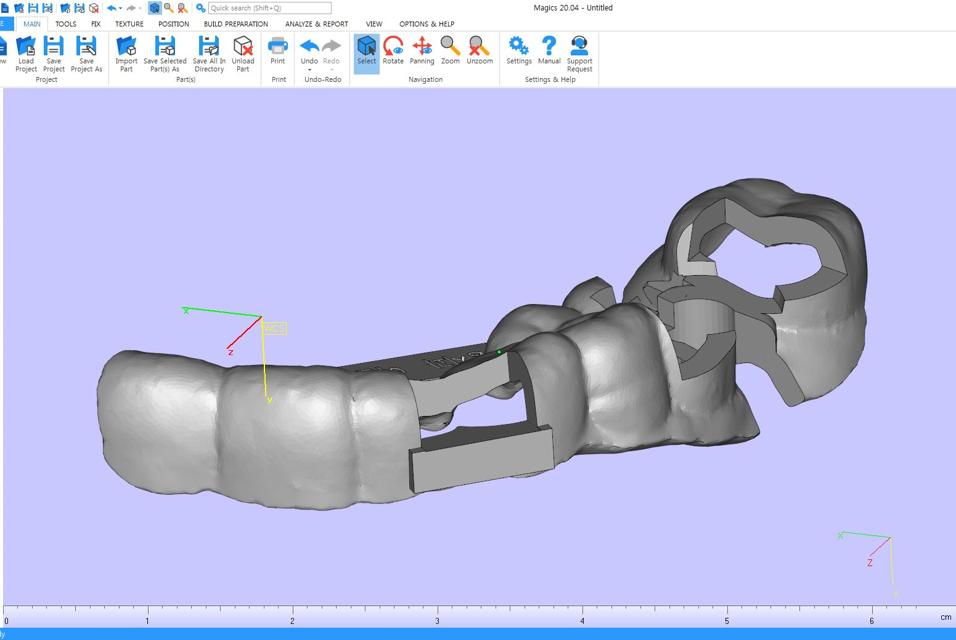

Thanks to 3D printing, patients requiring dental care no longer need to be continually present while the specialists create a digital model of their oral condition. They can scan the patient’s oral cavity and rely on the scan images to create a surgical guide. Working with a 3D-printed model saves significant time and money.

Repairing file errors with Materialise Magics

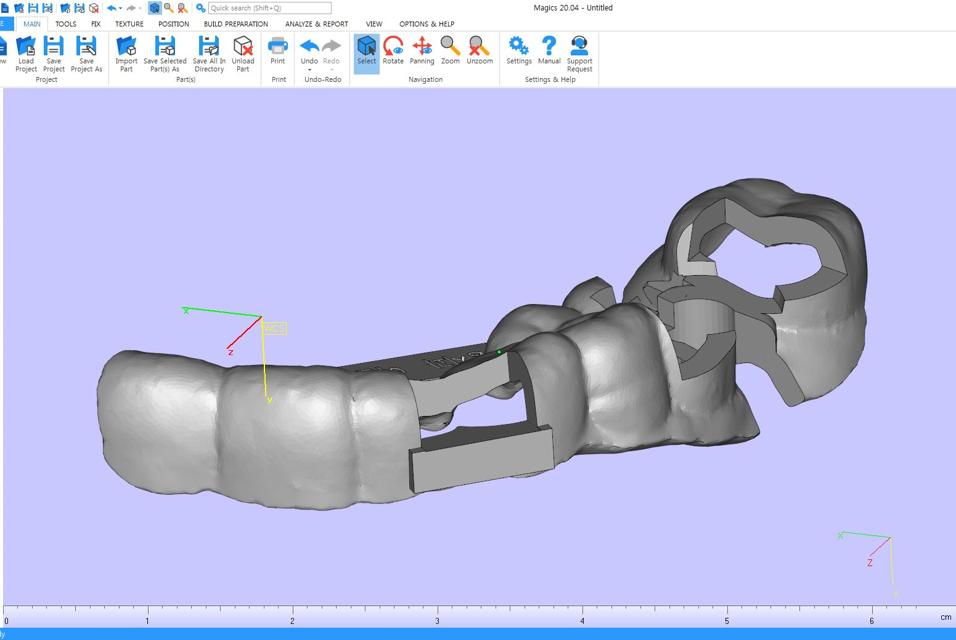

Converting a 3D scan to a 3D printing file format isn’t a flawless process. The result is a file that contains many holes, which makes it hard to successfully 3D print it. That’s why OSSTEM IMPLANT uses data preparation software Materialise Magics. This software package is the ideal tool to repair errors prior to the printing process. OSSTEM IMPLANT uses it to obtain watertight models, hollow parts and label them.

“We currently use Materialise Magics to validate STL data and improve the quality of the STL file, using the fixing feature. A better file quality improves the quality of the printed part as well. Since we can prevent build failures, we can save time and costs. We also anticipate that we will be able to save material and printing time with extended usage of the cutting and hollowing feature.”

— Jae Chan Heo, Senior Researcher at OSSTEM IMPLANT Co., Ltd. Implant R&D Center.

After repairing a model with Materialise Magics, the OSSTEM IMPLANT specialists send the file to their Stratasys Eden 350 printer. Materialise Magics and the Stratasys printers are perfectly aligned. Since Materialise Magics transforms files into watertight, 3D-printable ones, OSSTEM IMPLANT is able to get the surgical design successfully printed. After the printing process, the model is post-processed, measured and validated. Thanks to the customized surgical guide, the patient can then enjoy his or her new implant!

Share on:

This case study in a few words

Healthcare

Dental

Materialise Magics

Reduce build failures

Create watertight 3D files

Repair, hollow and label 3D models