CASE STUDY

Midwest Prototyping Reduced the Weight of SLA Molds by 42% Using Honeycomb Structures

If you aim to reduce costs and maintain the high accuracy of 3D-printed models, hollowing a solid part is a great way to achieve this. The downside is that this also decreases its strength and potentially its functionality. The new honeycomb structure in Materialise Magics resolves this issue, allowing companies to reduce material usage and printing time. As a beta tester of Materialise Magics, Midwest Prototyping was one of the very first to try out the new feature.

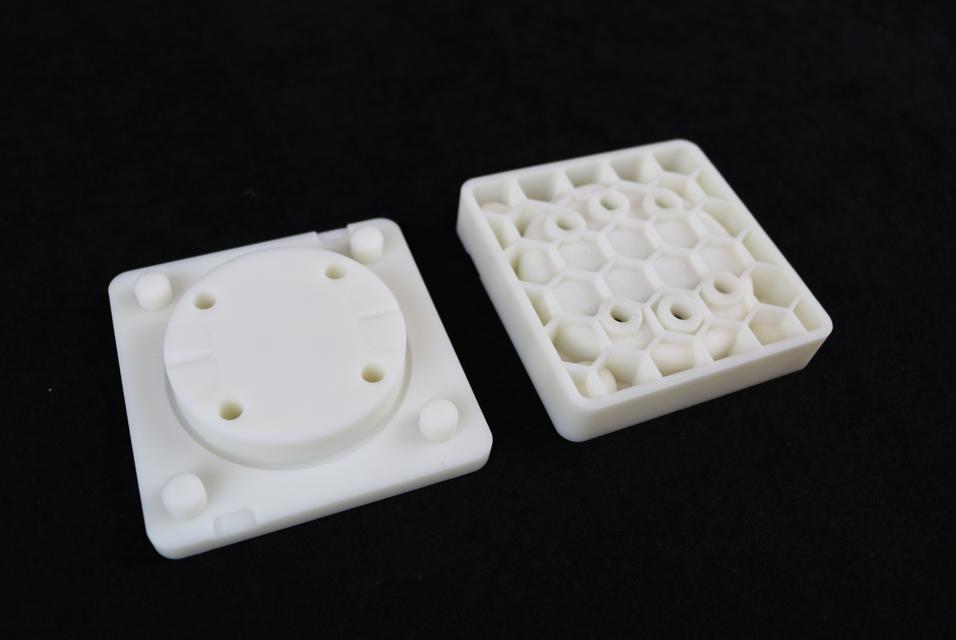

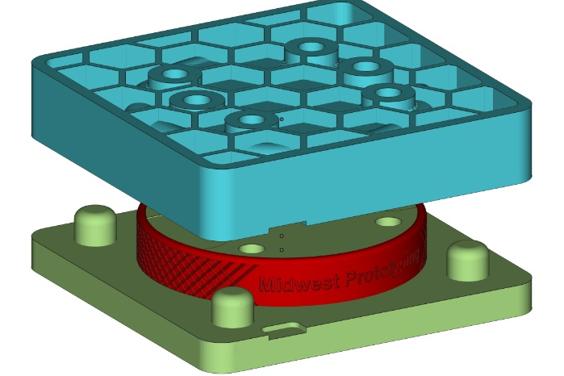

Design of SLA master with honeycomb structure in Materialise Magics

Reducing Nearly Half the Weight

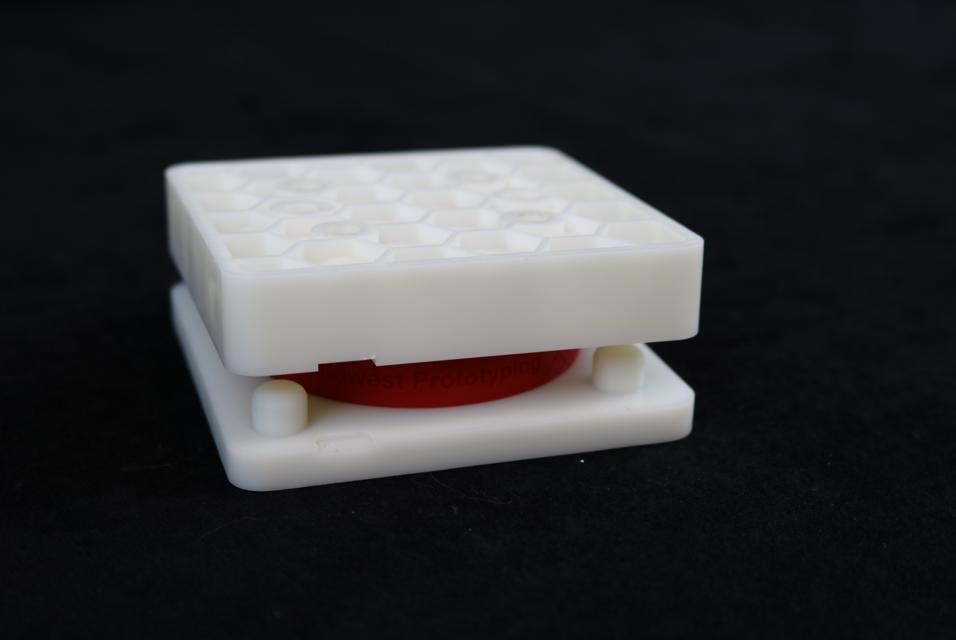

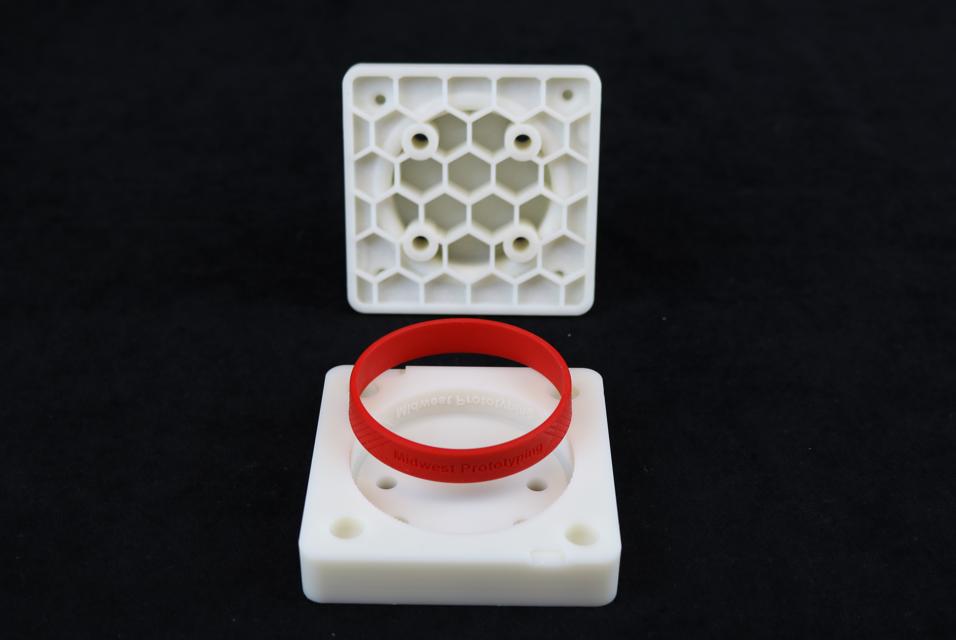

Midwest Prototyping used honeycomb structures to drastically reduce volume on 3D-printed master patterns that they use for silicone casting. Any design that has at least one large plane will largely benefit from the conversion to a honeycomb structure, Jijón explains.

“Honeycomb structures helped us reduce the weight of several SLA molds by an impressive 42.38%! We’re very pleased with the results. This feature is a prime example of Materialise’s cutting-edge innovation.”

— Alfredo Jijón, AM Specialist at Midwest Prototyping.

The benefits of this new feature and the incredible results reached by Midwest Prototyping are not limited to stereolithography, but can be achieved with various 3D printing technologies. For example, RapidFit, a Materialise company, successfully prints fixtures and jigs with honeycomb structures for the automotive sector with laser sintering.

Mutual benefits

Midwest Prototyping is a service bureau in Wisconsin that offers seven distinct 3D printing technologies on 20 machines, as well as low-volume production and a diverse range of post-processing techniques, all from their ISO 9001:2015 certified facility. It has established a longstanding relationship with Materialise. We deliver 3D printing software and Midwest Prototyping shares their user feedback.

“We really appreciate the opportunity to help Materialise develop new features of Magics. As 3D printing technologies continue to advance, having a way to match those innovations from the software perspective is tremendously helpful. Magics is a very powerful tool that helps us do our job faster and more accurately. Every new release gives us better, stronger features to keep up with our customers’ demands.”

— Alfredo Jijón, AM Specialist at Midwest Prototyping.

All images courtesy of Midwest Prototyping.

Share on:

This case study in a few words

Service bureaus

Materialise Magics

Reduce costs of 3D Printing while maintaining a high accuracy

Reduce weight and volume of SLA molds