CASE STUDY

Nanyang Polytechnic Streamlines its AM Production Process

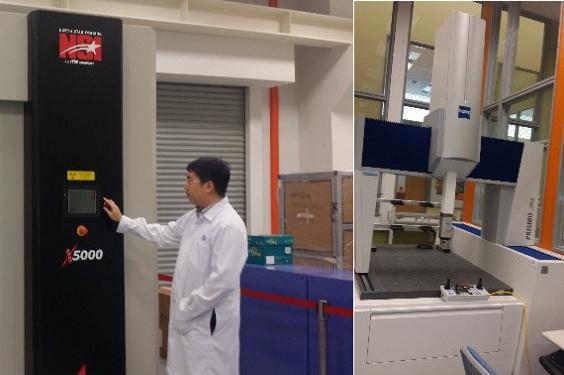

Singapore’s Nanyang Polytechnic (NYP) has been driving 3D printing technology innovation and adoption in Asia for 20 years with their additive manufacturing Innovation Centre (AMIC). The AMIC trains both students and industries in the core competencies in additive manufacturing and design, and innovative product development. To manage and sustain the additive manufacturing (AM) process of this center, AMIC has established a technology partnership with several leading AM vendors and solution providers such as Materialise.

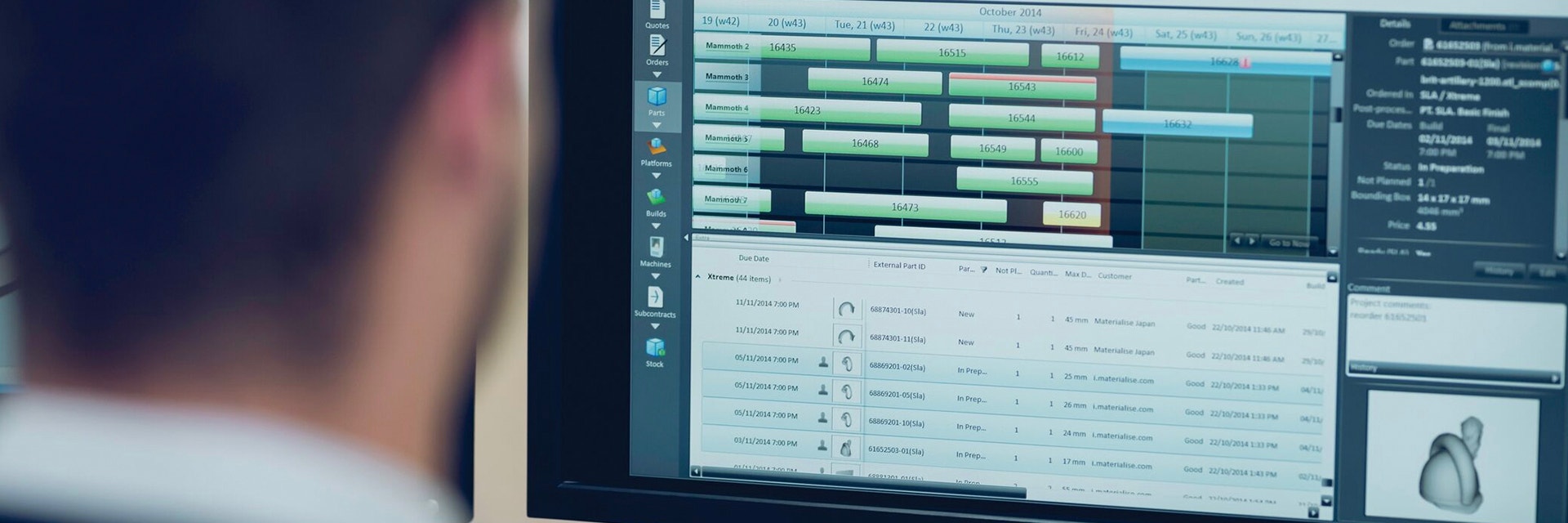

Besides training the students at the Polytechnic on the application of different AM technologies, AMIC also shares its know-how on the latest developments and industry best practices in implementing and managing additive manufacturing production processes with the industries that frequently engage with AMIC. For this purpose the AMIC has adopted Materialise’s AM production management system Materialise Streamics.

The Materialise Streamics database application, integrated with data preparation software Materialise Magics, ensures optimal order management, platform preparation, AM machine scheduling and communication within the center. It guarantees that the 3D printing process at the center is streamlined, under control and traceable. This is especially required for aeronautic and medical applications and allows these industries to adopt additive manufacturing faster.

“We are proud to be one of the first in this region to adopt a holistic approach that uses all the facets of additive manufacturing—technologies, applications, and processes—as a backbone to drive an efficient, qualitative and sustainable AM production ecosystem,” says David Wong, Head of the Additive Manufacturing Innovation Centre, Nanyang Polytechnic, Singapore. “Initiatives like these help create true additive manufacturing mindsets, critical to accelerate the adoption of AM as production technology,” explains Wim Michiels, General Manager of Materialise Malaysia.

The AMIC is now an integral part of the National AM Ecosystem that aims to drive broader industry adoption through its co-create, innovate, and incubate services platform to realize more viable AM solutions for the industry that will radically impact their manufacturing processes and productivity.

All pictures courtesy of NYP.

Share on:

This case study in a few words

Research & Development

Academia

Materialise Streamics

Production management system

Implement and manage AM production

Order management, platform preparation, AM machine scheduling and communication

How we helped

Plan and manage the entire AM process to maximize throughput, optimize capacity, and gain complete visibility across your operations.

Improve production efficiency, automate repetitive tasks, and optimize print success rates with industry-leading data and build preparation software.