CASE STUDY

3D Printing a More Efficient Food Supply Chain with Wakati

According to the United Nations, 45% of fruit and vegetables spoil before they reach the market, squandering almost half of the labor and investments. Instead of trying to double production, an inventive young Belgian product developer decided to tackle the root cause: storage!

The challenge

Keeping fruit and vegetables fresh before they reach the market

While working on his master’s thesis at the University of Antwerp, Arne Pauwels discovered that temperature is not the most important factor for preserving fruit and vegetables. On the field, it’s also hot, yet crops stay fresh before they’re harvested. He found that the key to keeping produce fresh is to keep them well hydrated: something that can be solved by placing them in a humid environment.

The solution

Tent and 3D-printed ventilator creates sterilized micro-climate for optimal storage

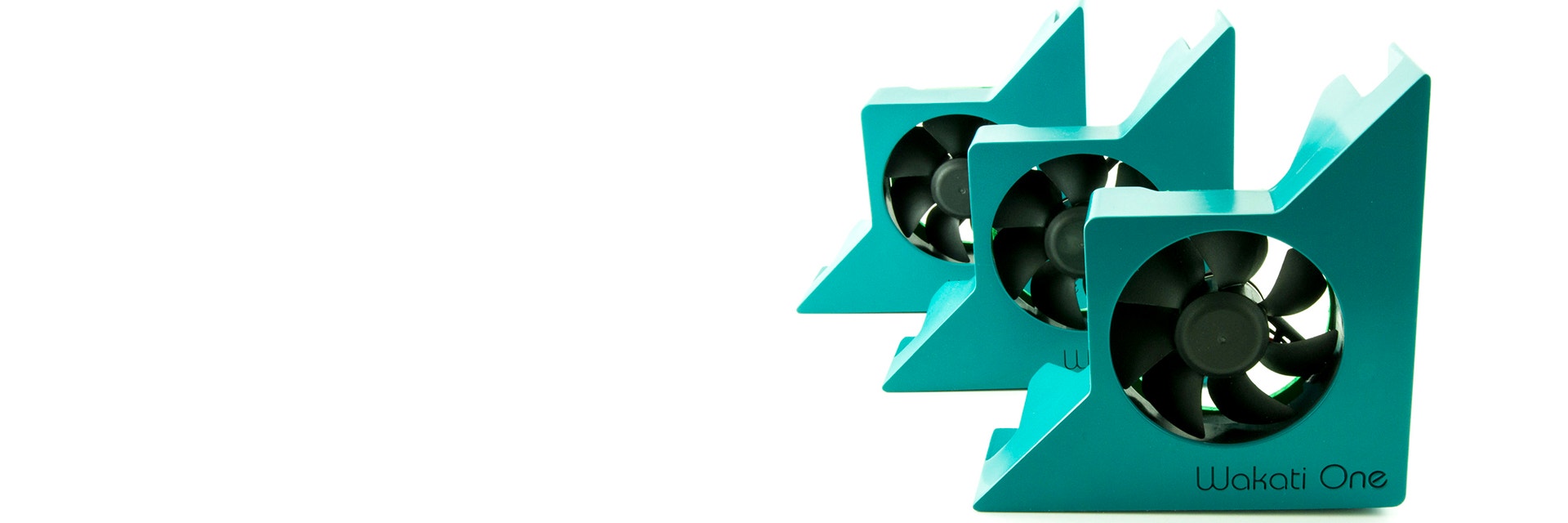

Inspired by evaporative coolers, he came up with the concept of Wakati. With a tent structure and a small solar panel of just three watts, Wakati creates a sterilized micro-climate that doesn’t require expensive cooling systems.

The Wakati climate-controlled unit uses less than 1% of the energy a refrigerator needs to run. With the entire solution costing a fraction of the common alternatives, limiting the expense of the separate components was key. As Arne put it, “For the housing of the ventilator, we turned to 3D printing. It enabled us to continuously optimize the design in the testing phase and allowed us to produce cost-effective, functional prototypes in fused deposition modeling (FDM) to convince investors and potential customers.”

The result

A first production run of 120 units

From a cost-effective pilot run to small series production, 3D printing at Materialise means bridging the gap between prototyping and manufacturing. The wide range of offered technologies makes it possible to choose the best technology for each step of the product development process. Once the final design was complete, it was printed in stereolithography to serve as a master for vacuum casting. This turned Wakati into a production run of 120 units in no time. Arne is delighted with the outcome: “In developing countries, there’s a major need for cheap solutions to limit post-harvest losses. Thanks to 3D printing, I was able to develop a product at a reasonable cost without compromising the sustainability.”

Share on:

This case study in a few words

Farming and produce

Fused deposition modeling (FDM)

Stereolithography

Lower prototyping and manufacturing costs

Design freedom