CASE STUDY

To See a Song: Materialise Designers Turn Abstract Idea to Personalized Car Speaker Grill Design

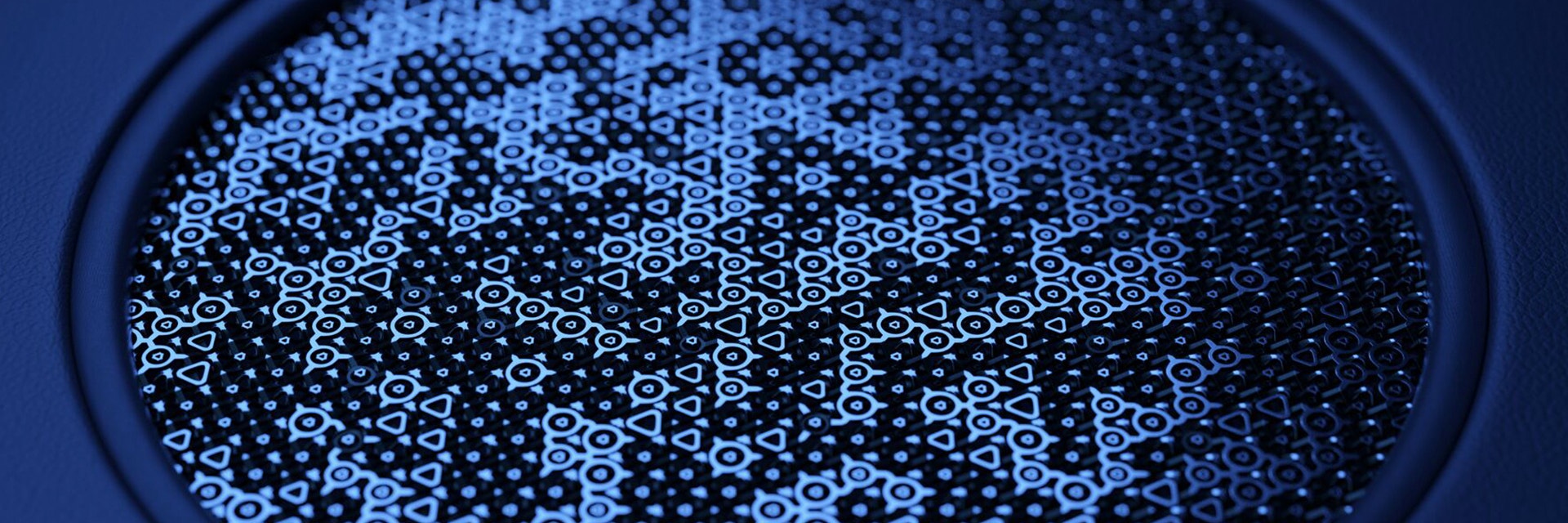

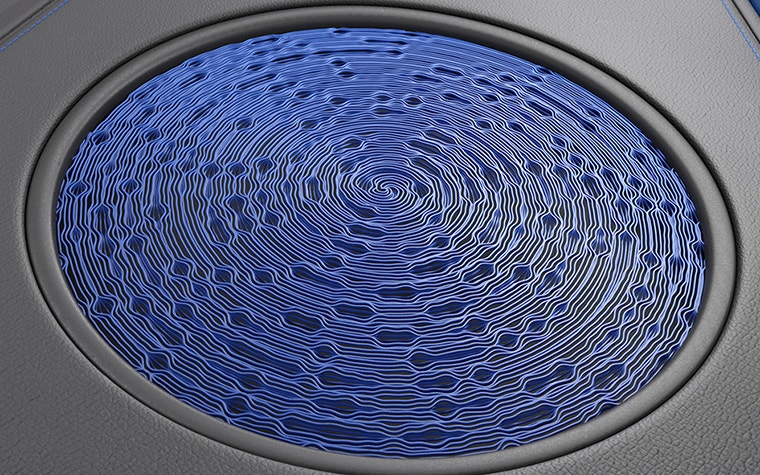

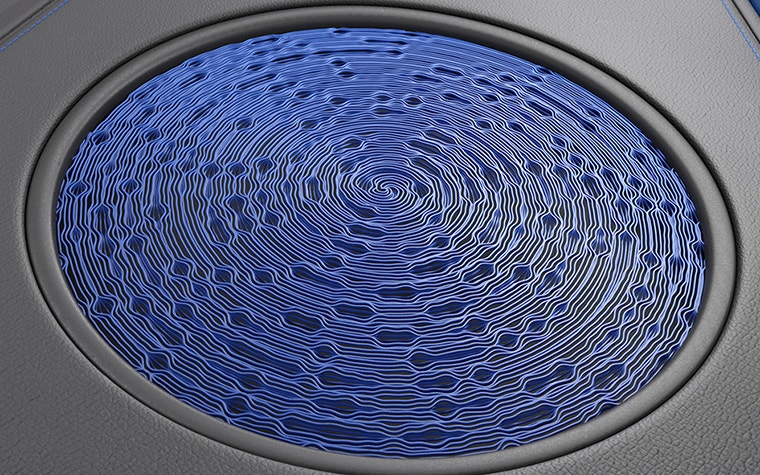

The project began with an idea that was quite basic: giving automotive brands a way to offer personalization in luxury cars. From there, our Design and Engineering team tapped deep into the design portion of their role, creating a concept that would enable consumers to make a car truly their own. A design that would allow drivers to not only listen to their favorite song while driving down the highway but to see it as well.

This case dives into what possibilities can be achieved when the Materialise Design and Engineering team applies their extensive design and additive knowledge to an abstract idea. Read on to discover how they made it possible to see your favorite song and make it a centerpiece in your car.

The challenge

Turning an abstract idea into a printable design concept

Our team of designers and engineers at Materialise often face the challenge of turning a broad concept into an effective, refined 3D-printed part. Customers come to us with goals they want to achieve and a vision they want to realize, but they need our experts’ know-how to find a way to make them a reality — and a well-designed one at that.

“Thanks to the combination of our team’s extensive design capabilities and 3D printing, it feels like we have countless opportunities to pursue ”

— Roman Plaghki, Design Engineer at Materialise

In this case, upon working with automotive manufacturers on 3D-printed parts for their latest model, our designers began to explore the idea of further personalizing cars. Thanks to the flexibility of manufacturing with 3D printing and these experts’ design expertise, the team was able to explore a completely unique idea that met the challenge of personalizing vehicles and turned it into a proper design concept capable of being customized and 3D printed at scale.

Watch the video to get a behind-the-scenes glimpse into the process.

Solution

Procedural modeling and 3D printing

Coming to a creative solution for a design is a journey. Conceptualizing a great idea is one thing, but how does the team go about making a design stylish yet feasible and printable? Let’s dive into the Materialise design process.

“When we first hear a customer’s dream for their product, we're instantly enthusiastic about the possibilities,” shares Roman Plaghki, Design Engineer at Materialise. “Thanks to the combination of our team’s extensive design capabilities and 3D printing, it feels like we have countless opportunities to pursue.”

Materialise designers go into each project with a simple equation in mind: the goal is to improve performance and interface while minimizing cost and harm. And above all, we design for additive manufacturing.

To begin with, our designers considered the needs of our clients — automotive brands — and the ultimate end-user. In this case, what kind of customization would a car brand want to offer for its luxury product lines? And what would a luxury car owner want their speaker grill to look like?

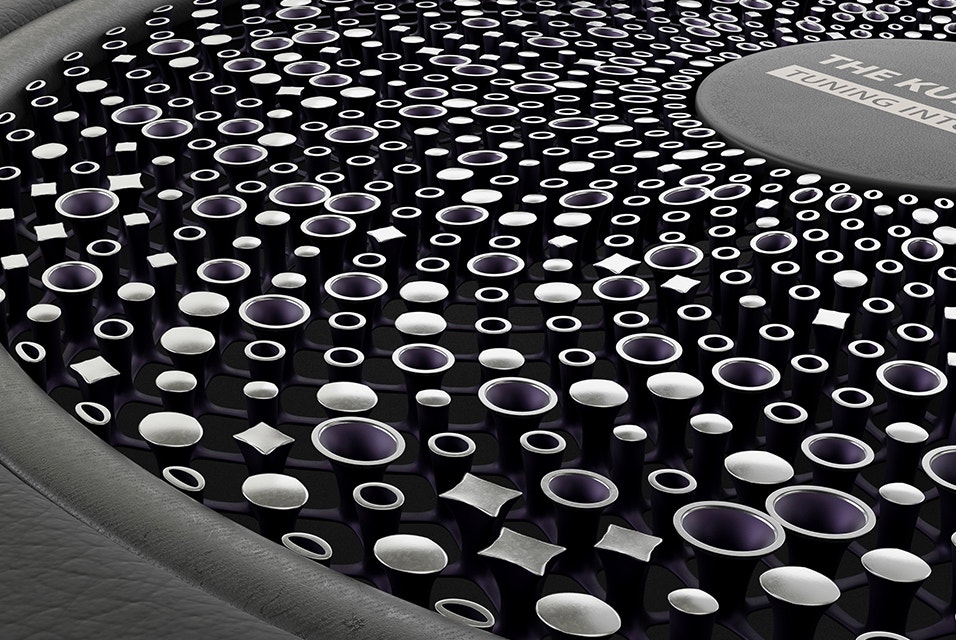

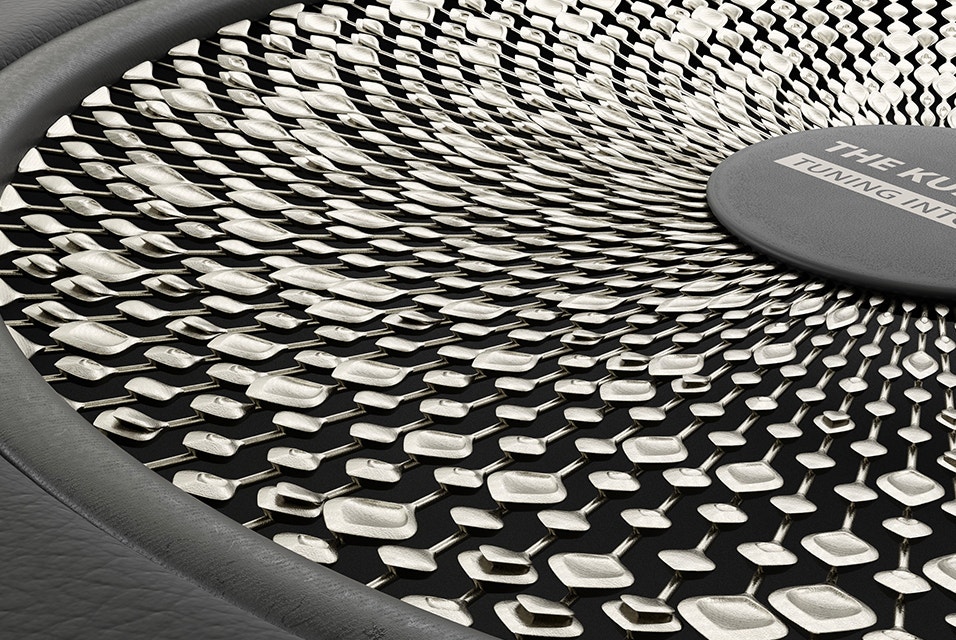

Additionally, additive manufacturing (AM) has a plethora of advantages, the main one being its capability to manufacture geometries that conventional methods could not. But being able to leverage this perk means that the designer must have a full understanding of the technology to create a model that fully reaps AM’s benefits. On the flipside, the designer must also understand AM’s limitations and design in such a way as to overcome them.

“Our team speaks 3D printing as our first language. Making designs printable is a bare minimum; we aim to design in a way that showcases the key benefits of the technology,” says Jurgen Roekens, Design & Engineering and New Business Director at Materialise. A design can be the most unique or beautiful, but without marrying this style with feasibility, it won’t accomplish its full potential. That’s why our designers’ third core value is to find the exact balance between aesthetics and function, so our customers don’t just receive an attractive model, but also an effective one.

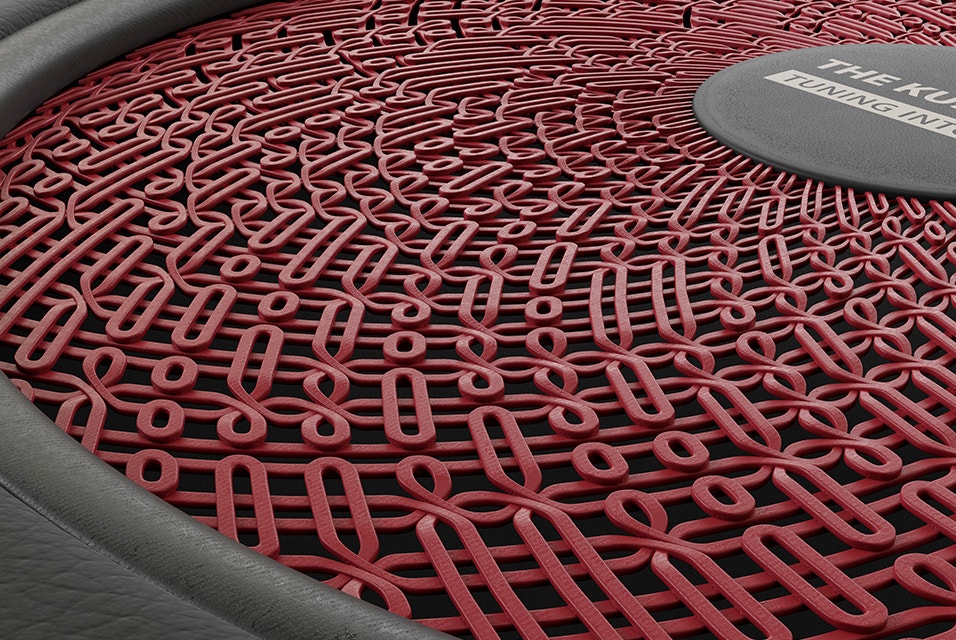

Putting all of these core values into action, the team got to designing — fine-tuning what it meant to visualize a song, how to best personalize the speaker grill with 3D printing, and how to make it an attractive yet feasible product. This took hours of creating algorithms, dissecting what makes each song unique, and collaboration among the team.

Result

Personalized car speakers

After digging deep creatively, the team had a concept that gives automotive brands a way to offer uniquely personalized accessories to their customers. With unlimited texture and pattern options, end-users can choose both the song they want on display in their car and the exact look that represents their style.

3D printing and its material options enable many possibilities, allowing our designers to avoid limiting their imaginations. This concept product is just one example of beautiful, functional, and personalized designs that are made possible when an abstract idea, a team of experienced designers, and a powerful manufacturing technique come together.

Share on:

This case study in a few words

Automotive

3D printing

- Personalization

- Design freedom

How we helped

Innovate and speed up your manufacturing in collaboration with our experts. Rely on our full range of in-house technologies suitable for all industries and applications.

Transform your product development cycle and get the best possible products to market faster. Get unbiased advice and dedicated support from teams committed to your success.