CASE STUDY

3D-Printed Jigs and Fixtures with a 40% Weight Reduction

Experts in the industry agree that 3D printing jigs and fixtures can make an immediate impact on automotive companies. By relying on 3D printing technology, companies can improve their efficiency and heavily cut expenses. In addition, the reduction of the lead-time is significant. SL Corporation, a company based in Korea and recognized worldwide for producing excellent automotive parts for over half a century, uses Materialise Magics software to get their automotive designs successfully 3D-printed.

Reducing lead times by 10%

SL Corporation uses 3D printing technology in several departments for design, prototyping and tooling. Next to the chassis, mirror systems and other automotive parts, they typically produce lightning systems. By making the switch from conventional manufacturing methods to 3D printing, they were able to easily produce parts that are difficult to manufacture, using the freedom of design that remains one of the main benefits of 3D printing. In addition, they could reduce the lead time of, for instance, the jig of an automotive lamp by 10%.

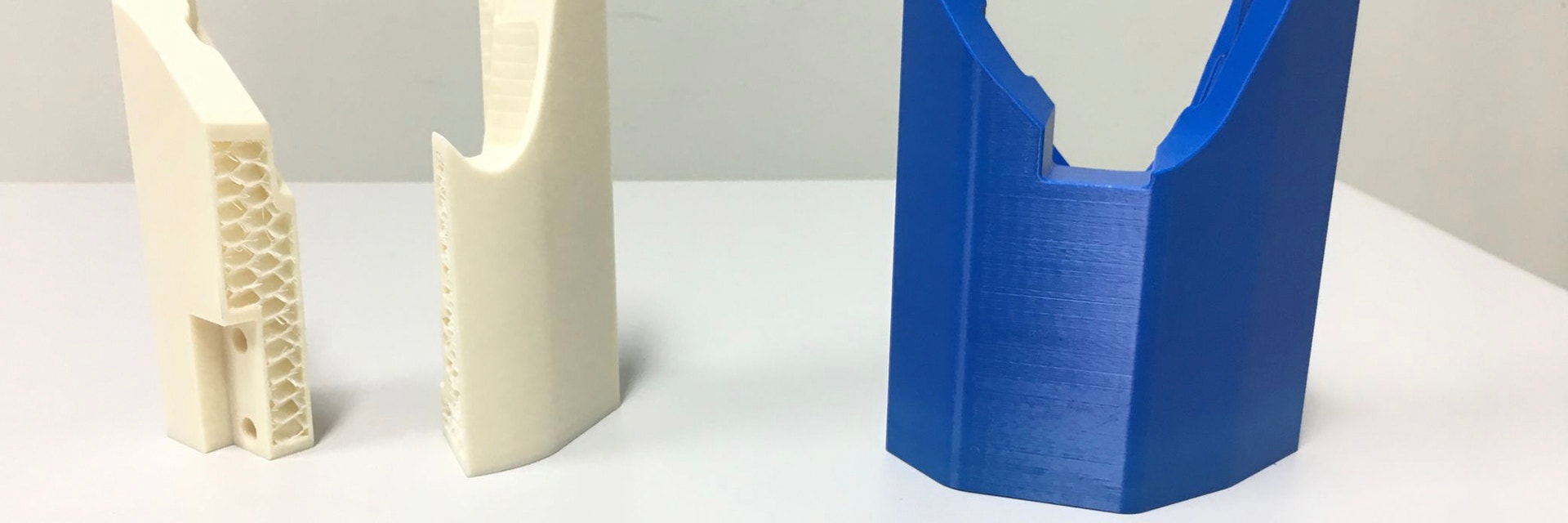

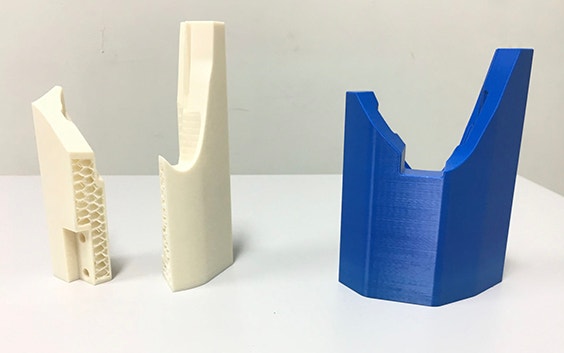

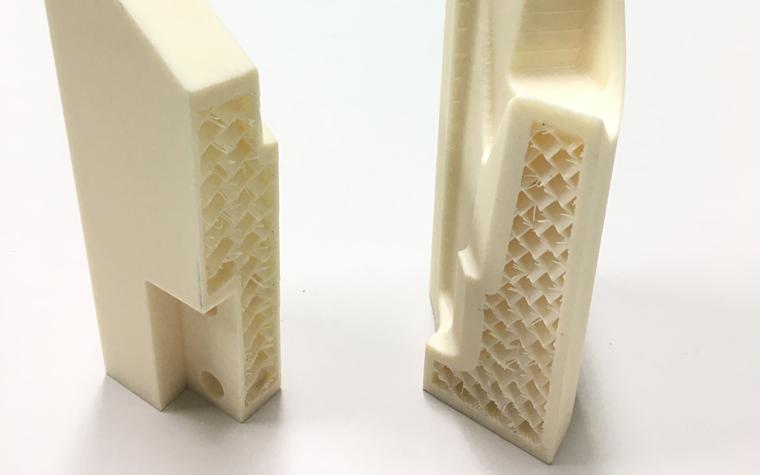

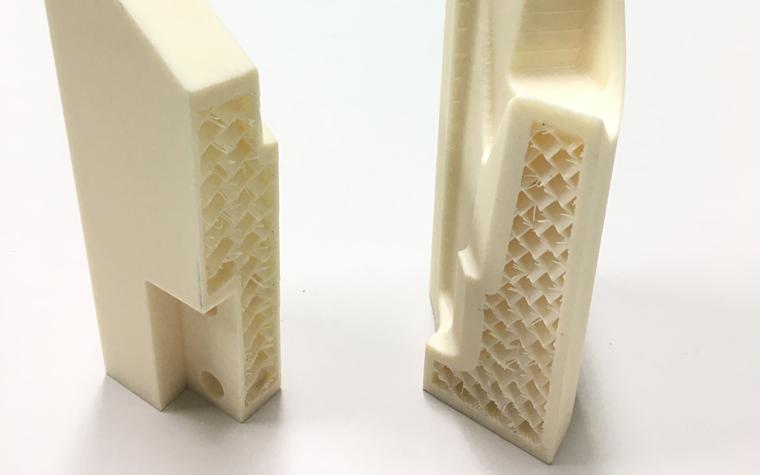

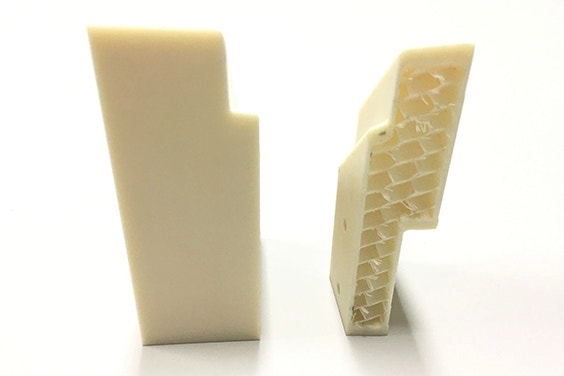

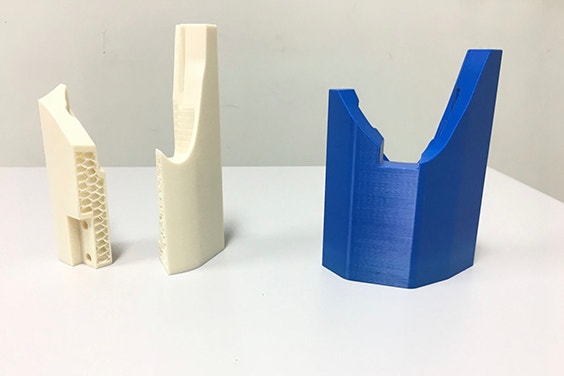

From a solid model to a lightweight structure

In addition to reducing their lead times, SL Corporation can save material and reduce the weight of jig loaders by 40%, by creating models with lightweight structures instead of solid models. By using Materialise Magics software, the design of the jig is error-free. Then they hollow it, taking into account the required wall thickness, and apply the structures to the model. These structures retain the strength of the original model. Finally, the cutting function enables SL Corporation to cut large jig loaders into pieces that fit the build platform and are easy to assemble afterwards.

“Materialise Magics is the ideal software to prepare jigs and fixtures for our automotive models for 3D printing. The advanced automatic fixing tool handles the most challenging errors. The hollowing function and generation of structures are also extremely useful. The weight reduction of 40% of our jig loaders really has a big impact.”

— Seong Jun Yu, Assistant Manager at the SL Corporation Production Engineering Center.

With 3D printing technology, in combination with additive manufacturing (AM) software, automotive companies can produce complex jigs and fixtures easier. SL Corporation could reduce the lead time of a jig by 10% and the weight by 40%.

Credit: SL Corporation

Share on:

This case study in a few words

Automotive

Materialise Magics

3D print the jig and apply lightweight structures

Create a lightweight jig

How we helped

Improve production efficiency, automate repetitive tasks, and optimize print success rates with industry-leading data and build preparation software.

Optimize and automate support generation with options tailored to different materials, technologies, and geometries.