EXPERT INSIGHT

Ziggzagg’s Collaboration Catalyst: Building and Maturing the AM Industry Together Via Magics’ Nester Module

Additive manufacturing (AM) has made great strides in the past few years — so much so, in fact, that convincing companies of 3D printing’s added value was yesterday’s challenge. Now, manufacturers and suppliers must collaborate to accelerate the adoption of AM and move it further into the mainstream. How? The easiest way to break down barriers and stimulate growth is by working together, using AM software to optimize processes and scaling volume production.

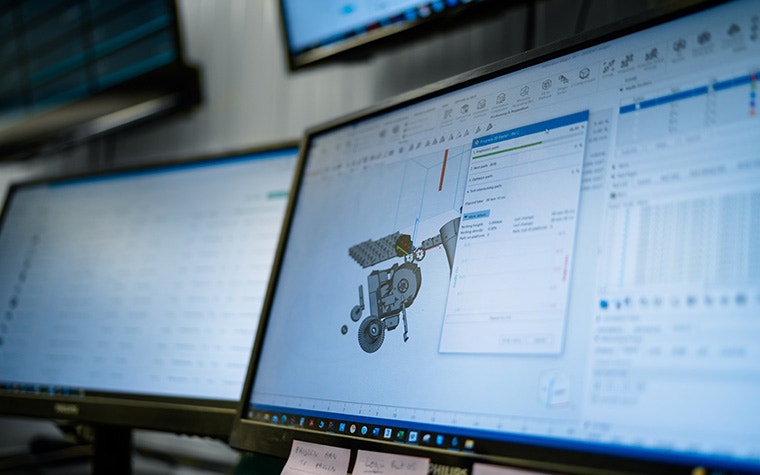

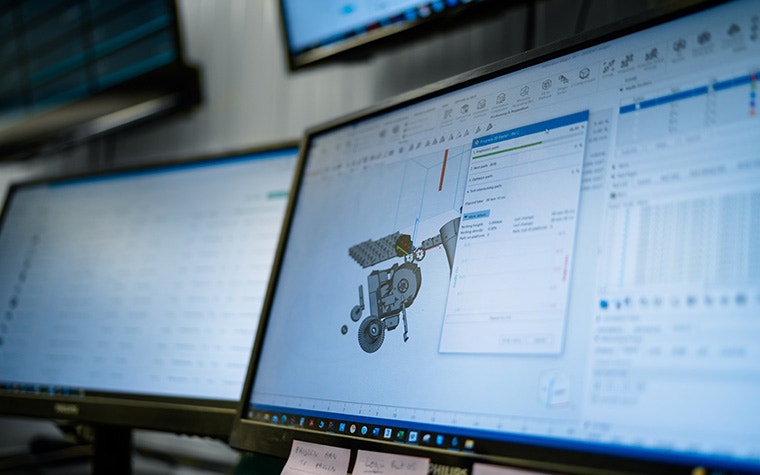

Often, this path isn’t linear. In Ziggzagg’s case, our long-time partner experimented with our software for years before striking gold with three AM solutions in particular. They’re long-term enthusiasts of Magics and the Nester module, using both for over a decade to boost the efficiency, consistency, quantity, and quality of their 3D-printed parts. More recently, they integrated the Magics Software Development Kit (SDK) into their pre-print workflows to further streamline their production and ensure customers get the exceptional AM parts they deserve.

Ziggzagg is a leader in industrial 3D printing, operating in sectors such as healthcare, orthotics and prosthetics, mobility, machinery and equipment, consumer goods, and more. “Our customers trust us to produce various parts, ranging from prototypes to series production,” says Michael Vandezande, CCO at Ziggzagg. “Furthermore, we want to be chosen by customers for our content, knowledge, quality, and speed: customers that appreciate they’ll end up with the best solution if they work with us.”

However, to maintain these lofty standards, they need software that can fulfill these requirements. That’s where our Pre-Print Software enters the frame.

Nesting: a puzzle like no other

Nesting is an essential process, and it’s like the puzzle game Tetris. The operator needs to snuggly fit together as many parts as possible into the laser sintering (SLS) or Multi Jet Fusion (MJF) powder bed to ensure a high volume/nesting density. Why is this a vital phase in a manufacturer’s production? It ultimately enables more efficient use of production resources while ensuring consistent part quality.

“Nesting is one of the most important parts of your production,” says Michael. “The better you nest and the better your nesting density is per run, the more parts you can produce, which increases your profitability. Also, the nesting and the intelligence you link to it, like the orientation, quantities, etc., are directly related to quality.”

Nesting is a big deal: getting this process wrong can be devastating for a business, resulting in printing errors, deformed parts, and material wastage.1

“In the past, before we introduced Nester to our production, we manually had to visually check everything and guestimate if it was accurate. As you can imagine, the process was terrible and took 2 – 3 hours per build. It was hell, but we literally had no other option.

“Then we discovered the Nester in 2013 or 2014, and we decided to give it a go because we loved Magics. We’ve used Magics since the company’s inception, and it’s played a vital part in all our projects; Magics is unchallenged when it comes to file repair, cutting, and hollowing. Our faith in Magics and the decision to use Nester paid off, and the rest is history,” states Michael.

Magics’ Nester module was designed to support our software and manufacturing departments. However, we quickly realized this could benefit our customers and the 3D printing industry. Companies like Ziggzagg have leveraged the tool’s capabilities ever since.

“Fried [Vancraen, Founder of Materialise] mentioned that the Nester module was developed internally. However, after a bit of market research, Materialise decided that manufacturers and the wider AM market could make good use of this innovation. In our case, we cut our nesting time in half — from 4 to 2 hours for our ten machines. The efficiency savings are huge.”

Software innovation has always been a catalyst for driving the AM industry forward. However, now, it’s serving another purpose. AM software is acting as what our CEO, Brigitte de Vet, calls a “collaboration catalyst.” Companies with similar mindsets use software to fulfill their ambitions and put AM in the spotlight in the broader manufacturing industry. Nester and our latest module, Magics SDK, lead the way.

Magics: the Swiss Army Knife of AM

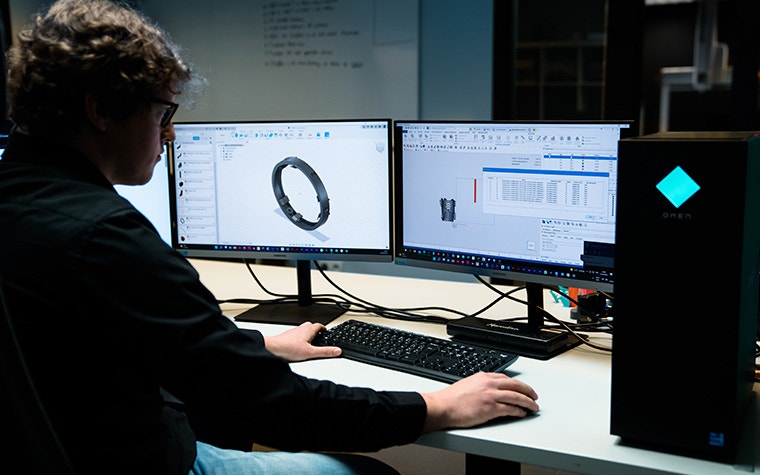

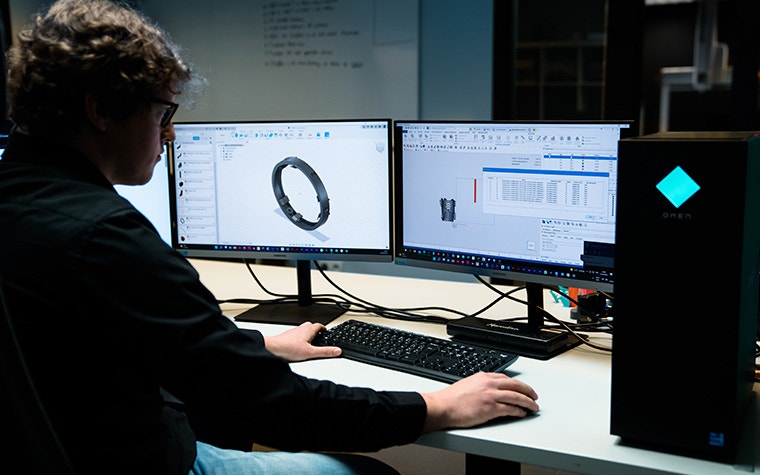

“The parts that come from our ordering system are already imported and orientated in Magics. We just look from afar and clear it [for the next step]. The process is even more efficient now that we’re using Magics SDK.

“Integrating Magics SDK allows us to automate 80 – 90% of the orientation and importing. We still evaluate and change things if they don’t make sense, but that’s rare. Switching to Magics SDK has saved our operators around 7 to 8 hours per week, freeing up more of their time to do other tasks while making us more efficient. The tool produced instant gains in our eyes, and we’re sure it will provide bigger wins down the road,” replies Michael, smiling.

Ziggzagg started using Magics SDK this year (January 2024), opting to deploy the tool based on our mutual worldview on 3D printing. After a hands-on session, they adopted the module into their workflow and now see great potential for it in their business in the short and long term. “You [Materialise] have always led the way regarding AM innovation, and we share a similar DIY mindset,” says Michael. “Although we operate in the same field and are rivals in certain areas, we have a very open dialogue and love to try new things. Neither company is afraid to use a solution that fits their purpose and constantly improve it.

“Typically, most software companies want to release a very mature package. We prefer using the latest technology, and then, if we spot any bugs, we report them. 3D printing operates in a rapidly changing environment, and we need to be agile, so we appreciate this speed combined with flexibility. We believe we perform better and faster with this mindset. These characteristics and philosophy are present in the Magics SDK. It’s an excellent tool that allows us to combine all the pieces of our puzzle together. Furthermore, whatever small kinks we do find are rectified immediately, as we have a clear communication channel with your team of experts,” states Michael.

Ziggzagg is using our software solutions to gain an edge in an increasingly challenging and fractured AM market. But they understand that to reach their ultimate destination, they need to collaborate with a like-minded partner.

Want to go fast? Go alone. Want to go far? Go together

What lies ahead for Ziggzagg? Their ambition is to be the one-stop shop for businesses looking for all things AM while also acting as a complementary service to the other organizations within the Seynaeve family/BMT group.

“3D printing is a commodity, and more and more companies are trying to make it a race to the bottom. However, we believe in providing quality at every stage of our production. It’s our USP: that’s why we provide design and consultancy in addition to producing AM parts. We offer a whole suite of solutions and services to solve our customers’ problems — and a key component of that is our knowledge and decades of experience with AM software tools like Magics and Nester.

“We want to be recognized as the agile, experienced expert, as well as a single point of contact for our customers that need to use multiple technologies. Magics offered simplicity, Nester optimized our efficiency, and adding Magics SDK and automation to our production has provided greater repeatability with less effort. We must increase efficiency and automate as much as possible, and these software solutions are a critical piece of the puzzle. The faster we are while producing error-free, first-time-right prints with the help of software, the better we will perform and meet our customers’ expectations,” exclaims Michael.

Software innovation, collaboration, and a shared mindset are the ingredients that will help the AM collaboration catalyst grow and make the wider manufacturing industry realize 3D printing's worth. AM sits alongside conventional manufacturing techniques, acting as an integral method to fill in the gaps where other techniques fall short.

“AM is not a future technology; it’s the right technology between other methods — the ‘go-to technology,’ if you will. We’re proud that we’ve worked on so many cool and important projects with our customers, from COVID-19 swabs to medical insoles and braces. Our company has reached new heights, and a big factor is due to Magics and Nester. We rely on them so much that we don’t even think about them — they’re fully part of the framework.

“The best thing is that we have a company that understands us. Materialise and Ziggzagg are legitimate AM players who work together, respect each other, and have the same mindset. AM is not the easiest business to work in, but we are building it together. And as Materialise builds the software and we provide relevant feedback, we’re both ensuring that our sector matures and grows together.”

1 3Dnatives: Nesting in 3D Printing Helps Optimize Space

Image credit: Ziggzagg

Share on:

You might also like

Never miss a story like this. Get curated content delivered straight to your inbox.