EXPERT INSIGHT

How 3D Printing at the Point-of-Care Can Support in Fighting COVID-19

The global COVID-19 pandemic has placed a significant burden on healthcare systems worldwide that are straining to handle the volumes of patients requiring life-saving treatment. We commend healthcare workers who are directly helping hundreds of thousands of infected patients during these uncertain times. Several countries have experienced, or are preparing for, shortages of critical medical equipment such as surgical masks, face shields, and life-saving ventilators. Some even struggle to provide the physical space and beds for patients. These seemingly fundamental necessities become a priority in a world of increasingly high-tech healthcare equipment.

Shifting priorities

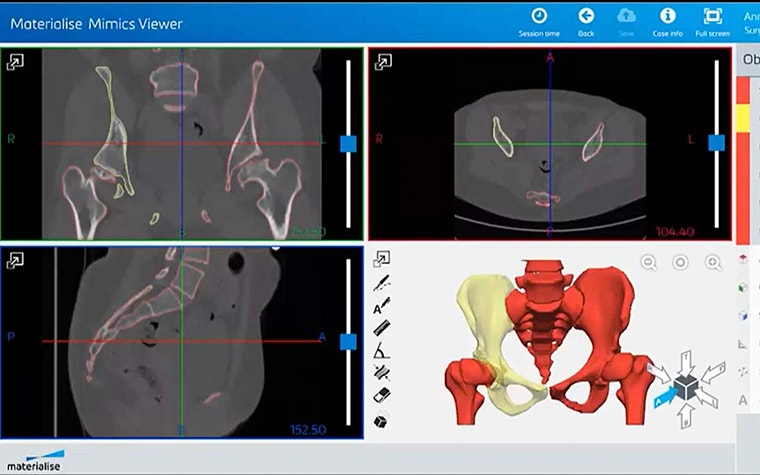

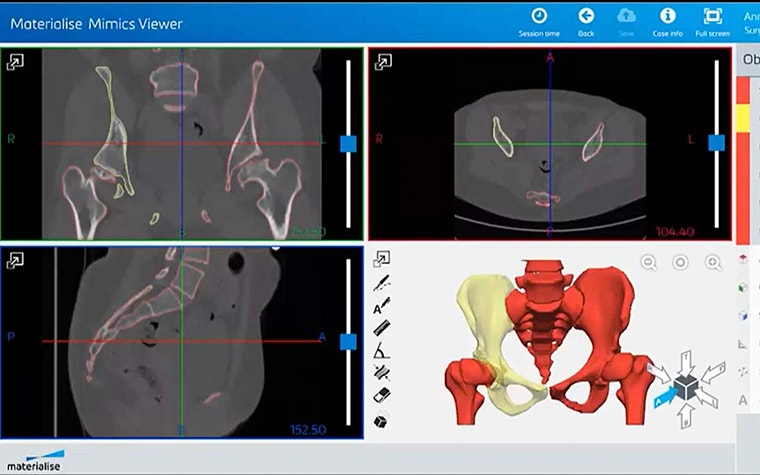

Many governments and health institutions have reduced or eliminated elective medical procedures in response to the spreading virus, justifiably saving valuable equipment and space for infected patients. While 3D-printed anatomical models are often applicable in an acute-care setting, for the most part elective procedures represent the most significant percentage of case volumes supported by 3D printing in the hospital. The shift in clinical priorities in response to COVID-19 provides the opportunity for these 3D-printing resources including software, equipment, and skilled personnel to be used in other ways.

Decentralized manufacturing advantages

The necessary actions taken to decrease COVID-19 spreading in our communities has reduced the movement of people and goods. This in turn slows the production and delivery of products where they’re most needed. 3D printing has become increasingly accessible in recent years and has supported the ‘decentralization’ of manufacturing, resulting in increased availability of 3D printing within hospitals and clinics. This has allowed for more rapid response to local needs of the healthcare facilities for applications benefitting from the technology.

With this recent growth in hospitals applying 3D printing resources closer to the point-of-care, there is an opportunity to take advantage of this distributed network of 3D printers. With less immediate demands to print traditional anatomical models while elective surgeries are suspended, the equipment can be reallocated to manufacture critically needed equipment during the crisis. Digital files can easily be shared via the web and manufactured where and when they are needed using 3D printing.

Necessity is the mother of invention

Door handles are among the most germ-infested objects in hospitals and other public spaces making them likely candidates to enable the spread of SARS-CoV-2. In response to this risk, Materialise designed several 3D-printable adapters to go over door handles to maneuver with an arm instead of a hand. These freely available files are being distributed via Materialise and have already been downloaded thousands of times. Several hospitals including the Mayo Clinic in the U.S. have begun printing these devices using their available 3D printing lab resources.

Additional stories have emerged and will continue as the crisis deepens in western countries — with 3D printing enabling both novel devices like the door opener while also supplementing critical equipment where there are shortages. This well-published story out of Italy is one example where critical breathing machine valves were 3D printed in less than a day to address the shortage for a large cohort of patients being treated.

Recently, grassroots efforts and crowdsourcing initiatives have taken shape as well where large pools of talented engineers and 3D-printing resources to be deployed towards the crisis. Companies such as HP and SmileDirectClub have also offered their 3D printing resources during this time to help cover shortages.

How Materialise is playing a supportive role

Materialise has contributed efforts towards limiting the virus spread while maintaining a focus on supporting our collaborators and partners during this time of need. In addition to freely sharing the digital files for the hands-free door adapter to reduce spread of the virus, we are supporting remote access to our software products to maintain productivity during mandatory home working periods in many countries.

This includes access to additional licenses of Materialise software to be used from home offices for our license holders, expanded access to our cloud-based Materialise Mimics Viewer solution to streamline remote communication, and ensuring our engineering experts are still available to support your applications.

L-101081-01

Share on:

You might also like

Never miss a story like this. Get curated content delivered straight to your inbox.