PATIENT STORY

From Superhero Mask to New Face and New Life Thanks to 3D-Printed CMF Implants

Born with hemifacial microsomia, Carlos Askew, a 21-year-old Kiwi never fit in — no matter how hard he tried. Growing up, he preferred hiding behind his favorite superheroes’s masks. This all changed when maxillofacial surgeon Dr. Derek Goodisson used TruMatch® CMF 3D-printed personalized titanium implants to mitigate his facial deformity. This pioneering operation was a first in New Zealand and enabled Carlos to face the world anew.

The congenital disorder hemifacial microsomia (HMF) is caused by an in utero vascular malfunction that results in the underdevelopment of structures related to the affected artery. In Carlos’s case, HMF manifested itself in facial asymmetry and left him partially deaf. If that wasn’t enough of a rough start, Carlos was placed in state care and shunted from family to family until he arrived on the doorstep of his current foster family, the Askews.

Now 21, Carlos wants what most young people his age want: a social circle, a job, and someone special in his life. But for him, his asymmetrical face remained the biggest obstacle to achieving this ‘normal’ life. An obstacle that made him feel worthless to a point where he contemplated ending his life.

CMF implants designed to fit

Thanks to 3D planning and 3D printing, Carlos can finally start building the life he has been dreaming of. To achieve this milestone, Dr. Goodisson worked in close collaboration with DePuy Synthes and Materialise engineers. Together they designed the personalized titanium implants that would mirror the non-affected bones, ultimately giving Carlos a more symmetric face. This complex surgery required a high level of accuracy, which is exactly where the PROPLAN CMFTM planning software played such a key role. This virtual planning and design process enabled the creation of personalized implants, as well as a predictable outcome from the start.

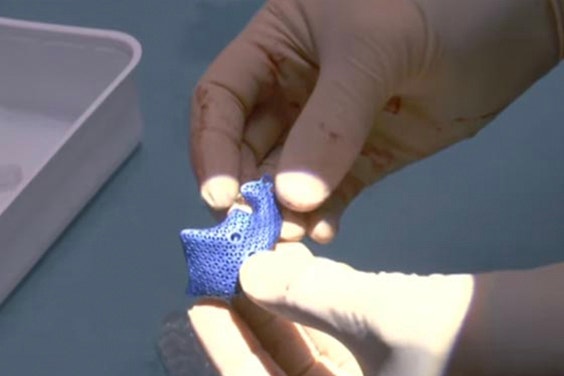

Left: Dr. Goodisson showing the PROPLAN CMF software and models he used to plan the surgery. Right: One of the facial implants used during surgery

Additionally, Materialise provided personalized drilling and cutting guides to predrill the screw holes for the implants and to mark the vertical portions of the sagittal split osteotomy.

A new face, a new start

This also reduced the operation time as the preoperative plan facilitated an accurate position of the 3D-printed implants, and, consequently, helped save time in the operating room. Once the personalized implants had been designed, approved, and 3D printed, Carlos was ready to undergo the makeover of a lifetime. Dr. Goodisson and his team worked for nine hours to separate and shift the upper jaw and mandible into a central position, before inserting the personalized titanium implants — an absolute first in New Zealand.

Carlos’ story showcases the true potential of 3D planning and 3D printing. PROPLAN CMFTM enabled the creation of detailed preoperative plans, allowed for the design of personalized implants and reduced the number of intraoperative decisions. It shortened the turnaround time, and facilitated a more predictable surgical outcome. The customized fit helped restore the symmetry of Carlos’s face. But more than anything, this pioneering surgery improved Carlos’s quality of life significantly.

Share on:

You might also like

Never miss a story like this. Get curated content delivered straight to your inbox.