CUSTOMER STORY

The Business Case that Started a 3D Lab

The North Manchester General Hospital in the UK is building a name for itself with its newly established 3D printing lab. The hospital is the largest of an NHS trust comprised of four hospitals in the greater Manchester area. The lab is powered by three full-time members who work with nine oral-maxillofacial consultants. The initiator of the lab, Mr. Oliver Burley, a reconstructive scientist, soon became the maxillofacial laboratory manager. His business case proved to be a very obvious path toward integrating a 3D lab in the hospital. Here’s how he built his case and how his success story developed.

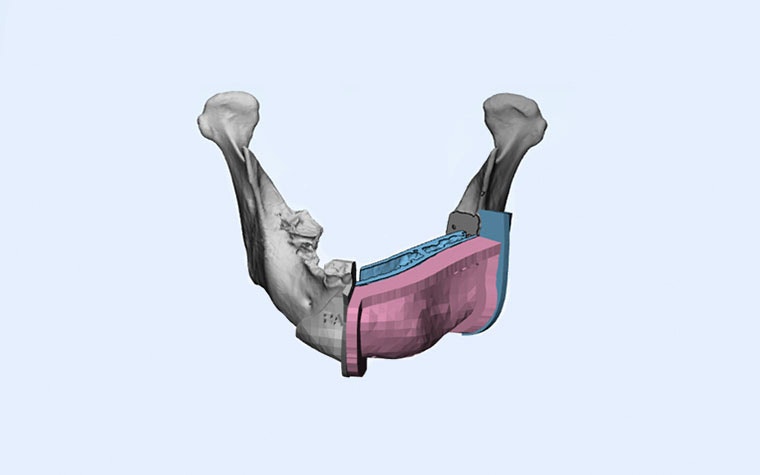

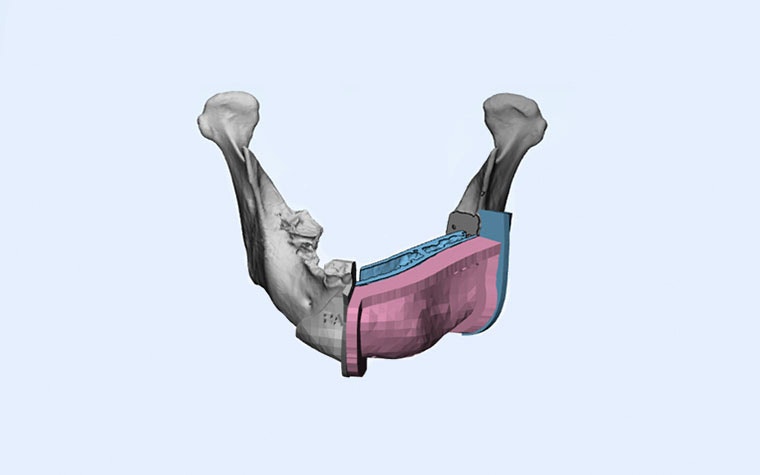

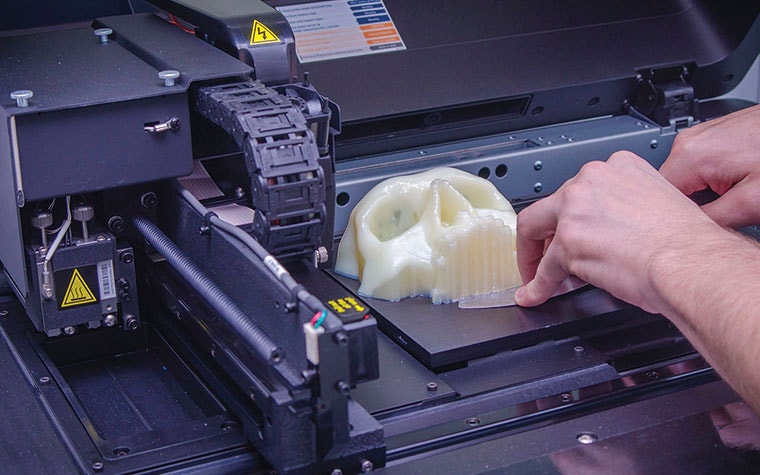

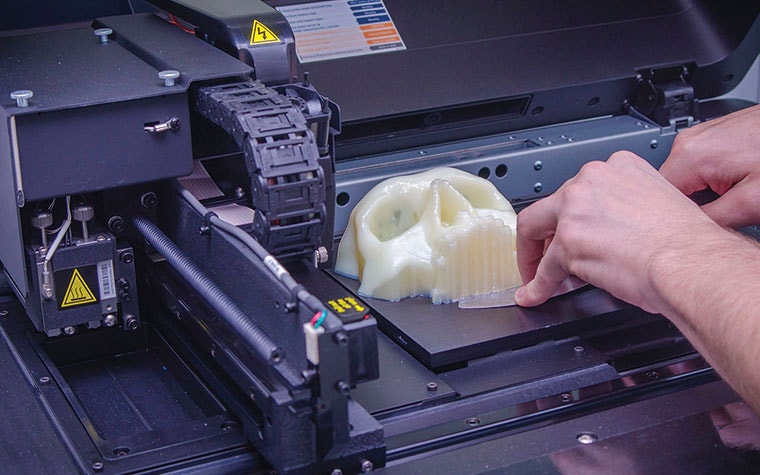

The lab’s main cases are head and neck cancer patients who require reconstruction. The first cases, for example, involved using DCIA bone grafts to reconstruct the upper or lower jaw of cancer patients. And there’s more. The specialized team in the lab offers patient-specific 3D-printed cutting guides and models for diagnostic use and planning. In addition, the lab team has added trauma work to their repertoire. This entails printing a head model, resecting it in 3D, and pre-bending the titanium plates that will hold the skull together.

"We’re using 3D in virtually every case now," says Mr. Oliver Burley, Reconstructive Scientist at North Manchester General Hospital in the UK.

How did 3D printing enter the center stage?

Mr. Burley already started using Materialise’s 3D medical software during his three-year MSc program in reconstructive science, which he started in 2013. Soon after he obtained his master’s in August 2017, Mr. Burley pursued a career intertwined with medical 3D technology in a management position at the North Manchester General Hospital.

Already understanding the benefits that 3D technology brings to patient care, Mr. Burley took the next logical steps in integrating a 3D printing facility in the hospital. Once settled in his new position, he almost immediately started building a business case. The hospital was already open to the idea of implementing 3D printing in-house — they just didn’t have the skillset and knowledge yet. Mr. Burley’s expertise came in just at the right moment.

Why have an in-house 3D lab?

Patient planning or care that includes 3D printing is getting more and more obvious. "Patients are more aware of the technology, and one even asked if it’s included in the North Manchester General Hospital," says Mr. Burley. "It’s become part of patient expectations."

"Moreover, as a cancer center, you need to have an MDT, a multi-disciplinary team," explains Mr. Burley. "It needs to fill certain criteria, and one of these is having a restorative consultant. I envisage that in five years’ time, if you want to be a fully-fledged cancer center within an NHS Trust, one of the requirements will be to have a 3D printing facility. I feel that’s the way it’s going."

Tailoring a 3D lab to your hospital’s needs

It was important to first understand the requirements of the department in order to move forward and decide what type of 3D printer to get. This included materials, what type of models would be printed, what the timescale for the printing was, and the upkeep of the printer itself. Mr. Burley eventually went for a PolyJet 3D printer.

While making a choice about which software to use, Mr. Burley looked more closely at the department needs and which Materialise package would fit best. The Materialise Mimics was chosen as it covers the workflow of DICOM segmentation, device design, and 3D printing preparation. Then, being a cancer center, the team would be looking at surgical planning, reconstructions, and jaw osteotomies. ProPlan CMF was the software of choice for these tasks.

"There have been a few difficulties with getting some of the consultants onboard with the idea of 3D printing, but ultimately, it was rather easy to convince them," says Mr. Burley. "Even one of the most conservative surgeons came to ask for a consultation and yielded positive results."

Building the business case

Cost is another big element of making your plan, says Mr. Burley. Initially, the hospital was spending 120k pounds on outsourced 3D printing projects annually. Mr. Burley started by making a financial plan, looking at the cost of the materials, material consumption — how much it would cost per gram, per type of material, per model — printer maintenance, licenses, staff members, and the number of expected cases. This last part was set to 20 cancer cases per year and then perhaps 8 – 10 trauma-related cases.

Another key consideration was to try reducing OR time, which also means reducing the time a patient spends under anesthetic. The aim was to improve patient outcomes by reducing the amount of bone being wasted during an operation, such as a bone graft. Previously, the bone used for the graft would have to be cut bigger than necessary to leave a bit of margin in case the original measurement wasn’t enough. Now, with planning in 3D, the bone can be cut precisely to fit its new location.

Mr. Burley also took a look at how communication with the external partner could be time-consuming. Having the lab in-house would foster easier collaboration with the medical team and provide accessibility to the lab.

By looking at all these aspects, Mr. Burley has achieved significant financial savings for each case they worked on in-house. One of the lab's main costs is software licenses, but as these licenses remain the same price during the whole year, the more cases you have, the lower the costs. So, financially, setting up a 3D lab in-house was an obvious choice.

Finding the funding

As for funding, the lab had the good fortune of a generous patient donating enough funds to cover the costs of the printer. After that, Mr. Burley looked at many alternative ways to raise funds. “Don’t just look at what you can be given but at how you can get it via other means,” says Mr. Burley. Look at the big picture and all the possible avenues that can provide funding. Getting creative, Mr. Burley even wrote to the Manchester football club to ask for funds, offering a possible exchange in service when there’s a sports injury. We’re all looking forward to a response.

Future plans

Mr. Burley expects the lab to snowball. As of the first case in late mid-October, there have been four cases in four weeks. At this rate, their prediction of 20 cases per year will soon be a distant memory.

"We now have the resources and ability to use the software," says Mr. Burley. The original goal for the lab was to use it for head and neck reconstruction cases, but now, they take in smaller cases as well.

Mr. Burley hopes the use of the lab will expand to include other departments such as orthopaedics, neurology, and rheology, and he wants to increase the lab’s capacity accordingly. This will also contribute to bringing in revenue. He’s also planning to ask other hospitals to participate in using the lab.

Spread the word of your lab

Mr. Burley highlights the importance of making your lab known. People are aware of the technology and are interested in how to use 3D printing. To give your lab good momentum, involve as many people as you can: create a newsletter to keep people updated on your progress and projects. Being part of a worldwide community filled with passionate people who share their insights on their 3D printing experience, their inspiration for future projects, or innovative ways of using 3D technology is an essential element in making your 3D lab a success.

Medical 3D printing is becoming a standard part of modern patient care. Wouldn’t a logical next step be to investigate how to integrate the technology in your hospital? If you’d like to know more about it and how your patients can benefit from 3D printing, get in touch with us! We’ll help you walk down a new path and get you started.

Share on:

You might also like

Never miss a story like this. Get curated content delivered straight to your inbox.