EXPERT INSIGHT

Stay Cool and Brace for Impact! Filter the Cracks in Your Design Using 3D Lattices

Hi! My name is Silke Cleuren, and I’m a scientist at heart who loves solving problems and analyzing how things work. I’m also passionate about nature and the animal kingdom too. These interests have inspired me and guided me in my academic life: I achieved a master’s degree in evolutionary biology and then a Ph.D. investigating how snakes evolved to possess such optimally shaped fangs. This involved analyzing their shape using 3D software and quantifying their strength with finite element analysis (FEA).

To help me with my research, I used Materialise Mimics to create 3D models from CT data and Materialise 3-matic to build and test these models for stress and strain simulation.

The amazing thing about 3D modeling software is that it allows you to experiment and adapt your ideas in real-time. After using them for my research, I’m a big fan of such tools, but I always felt there was more to discover. Now that I’m working at Materialise, I’m able to investigate 3D modeling to its full potential.

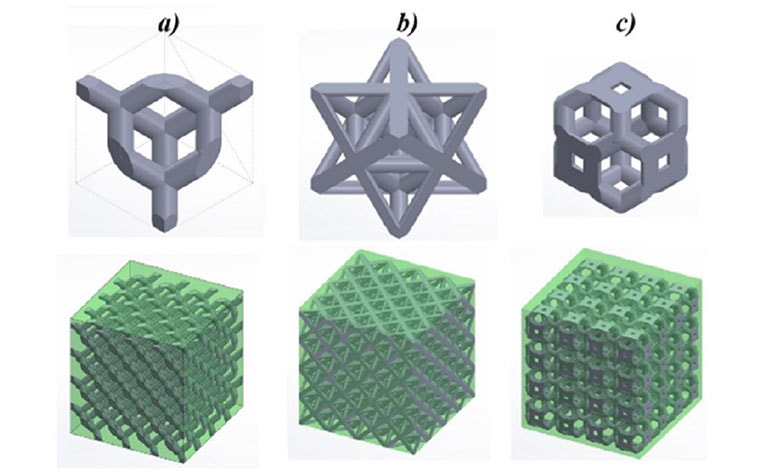

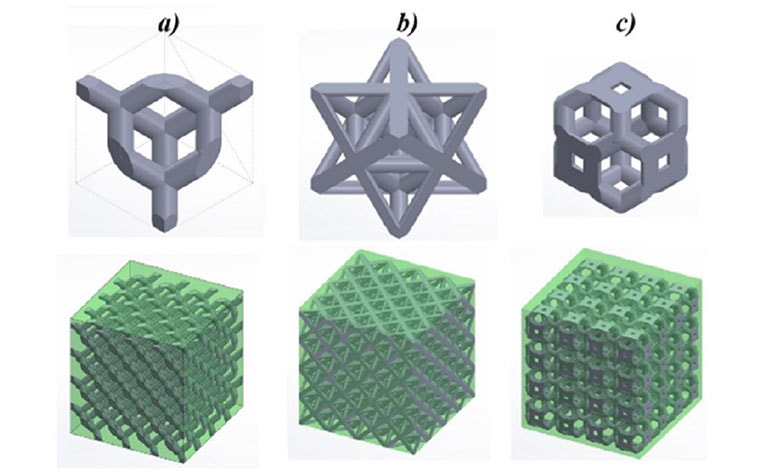

A little while ago, I came across an excellent review paper by du Plessis et al. (2022), exploring 3D printing and modeling in more detail. Specifically, it discusses the potential of lattices in additive manufacturing (AM). A lattice is a 3D repetition of a building block — the unit cell — consisting of a particular geometry of beams and nodes to create a structure.

The paper describes numerous use cases for lattices, as they’re ideal for weight reduction, impact absorption, permeability, heat exchange, and thermomechanical applications. The authors also highlighted that a user might finetune lattices for specific properties. A designer may adjust parts to suit a particular stiffness, increase the surface area, analyze specific failure criteria, check for deformation, and much more.

This article will focus on three applications — heat transfer systems, energy absorption, and fluid permeability — and show how you can achieve these functions using 3D lattices.

1. Lattices for heat transfer and cooling systems

Metal lattices can serve as groundbreaking heat transfer systems. With 3D lattices and AM, users have the ability to create thermally efficient structures with highly complex and miniaturized designs quickly. Several applications exist that use 3DP, such as heat exchangers, cooling systems, catalytic converters, and electronics in 4D printing, to name a few. However, one of my personal favorites is adding lattices to insulation layers used in aerospace designs. These lightweight layers have integrated channels that guide hot air from the engine towards the wings for de-icing.

Also, lithium-ion batteries use lattices for thermal management. Such structures are included inside the cooling channels for increased fluid velocity, improving the cooling effect. Finally, injection molds for parts needing more rapid cooling incorporate lattice designs.

Pro tip: there are numerous ways to create 3D lattices. You can convert triangulated mesh surfaces into lattice beams or use unit cells (from the 3-matic unit structures library or made by yourself) as the building block for the lattice. These can fill entire volumes or can be placed on top of or in between surfaces. Creating the lattice in 3D design software enables the user to edit the lattice further (attach, attract, filter beams, vary beam thickness, etc.).

Different lattice types available in 3-matic: first mesh-based, next, unit cell-based, and lastly, UV-based conformal dual-faced lattice.

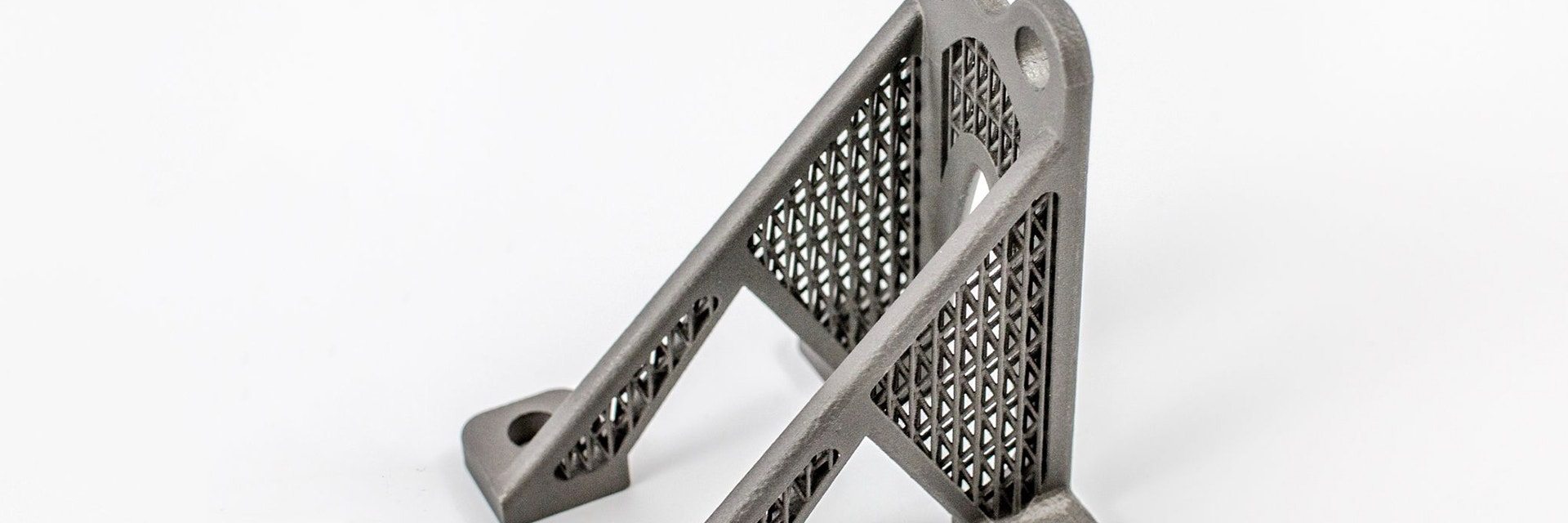

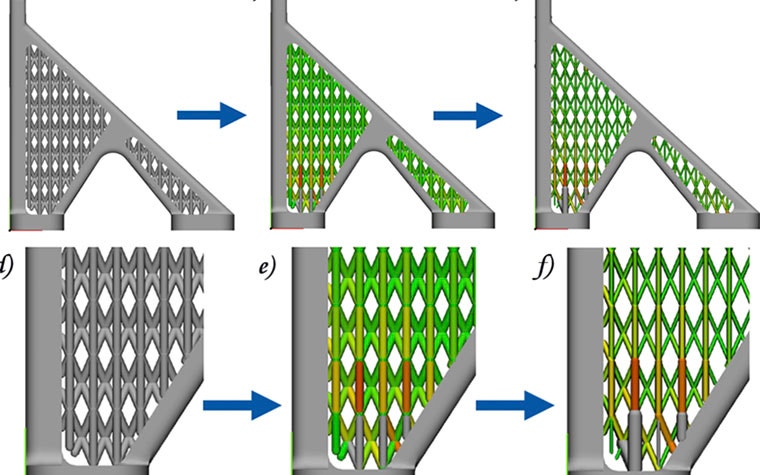

2. Lattices for energy and impact absorption

Lattices are great for withstanding certain loads without collapsing; however, 3D-printed lattices are ideal for impact absorption applications as well. Polymer lattices are used in helmets for better protection and in 3D-printed running shoe soles that help cushion the impact of the runner’s body weight. Automotive and aerospace industries also use metal lattices in their applications for better impact protection due to their lightweight properties.

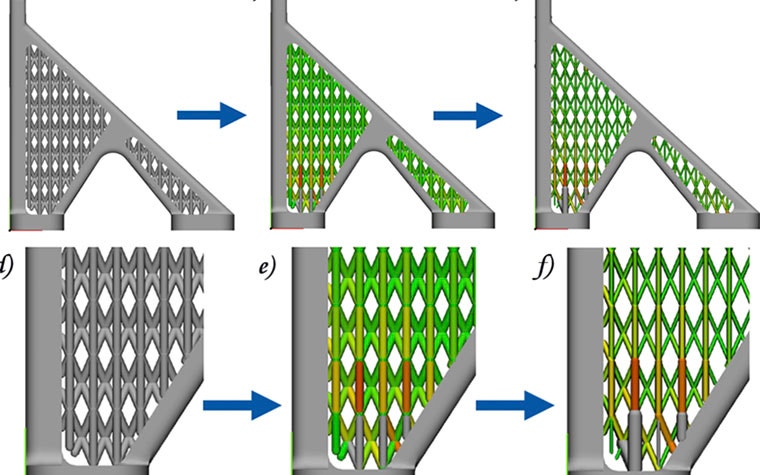

Pro tip: users can create suitable lattices within 3-matic and adjust the beam’s thickness manually (e.g., the longer the lattice, the more the beam thickness increases), as well as based on simulation results. This causes thicker beams in locations that experience higher stress.

3. Lattices to help with fluid permeability

Finally, the spaces between the lattices, or the porosity, can also vary. This is useful for designs that require filtering systems. Medical implants can benefit from degrees of permeability as lattices allow nutrients to flow through the structure, potentially improving bone ongrowth and ingrowth (du Plessis et al. 2022). Other applications need permeability — such as hydro-cultures, filtration systems that incorporate chemical interactions, and thermal conductivity — to function sufficiently, too.

Pro tip: designers need to create lattices with either set or gradient/adjustable pores. The Voronoi structure is one of several creative designs used in 3-matic. While using this software, meshes can be divided into specific regions manually or based on analysis results (simulation, wall thickness, etc.). Once this is done, specific pore sizes can be assigned to these regions. You’re also able to create lattices using a unit cell and the pore measurement tool to measure the diameters present in the openings that make up your lattice structure.

A cylinder with predefined sections and conversion to varying pore sizes using Voronoi.

This article only touches briefly on the versatility that lattices have to offer. However, I hope I’ve piqued your interest in using them in your future designs! 3D modeling and lattices are ideal for various applications. And using dedicated 3DP software, such as 3-matic, can help you integrate lattices into your plans and optimize your 3D-printed parts.

Share on:

You might also like

Never miss a story like this. Get curated content delivered straight to your inbox.