TRENDS

What Holds Companies Back from Fully Integrating Additive Manufacturing?

Organizations are no longer asking whether or not additive manufacturing (AM) is a valuable manufacturing method. Companies from various industries undoubtedly recognize the technology's impact, and the question on their minds has now evolved into 'how do we use AM successfully?'. We commissioned an independent survey of 327 large manufacturing companies in the United States, Germany, and Japan to better understand this mindset and what holds companies back from going the distance with AM.

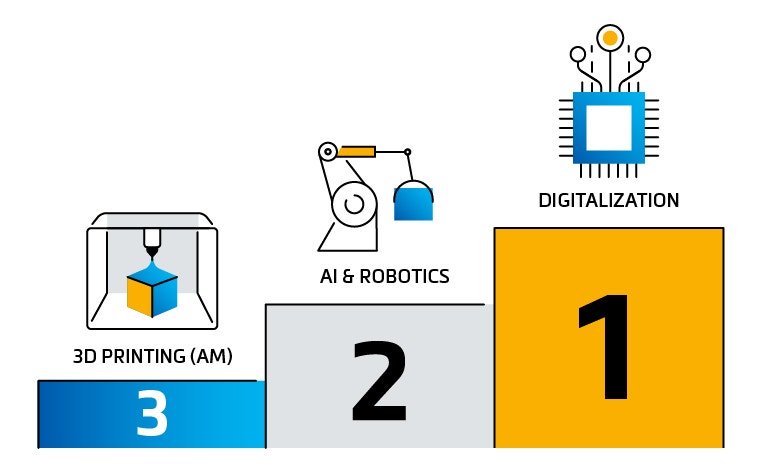

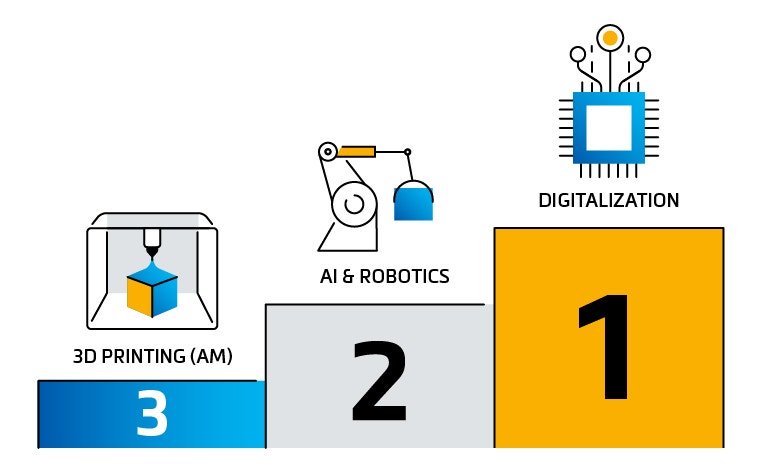

What's trending?

With digitalization as the leading trend in production lines, it's no surprise that additive manufacturing — a technique that fully embraces digital workflows — follows closely behind. Other top trends significantly impacting manufacturing include artificial intelligence, robotics, supply chains, and employee shortages. While employee shortages could appear to be a barrier to AM adoption, AM is actually a potential solution to this challenge. Because of its digital nature, AM uses automated workflows that allow companies to better distribute their workforce, minimizing tedious, manual tasks.

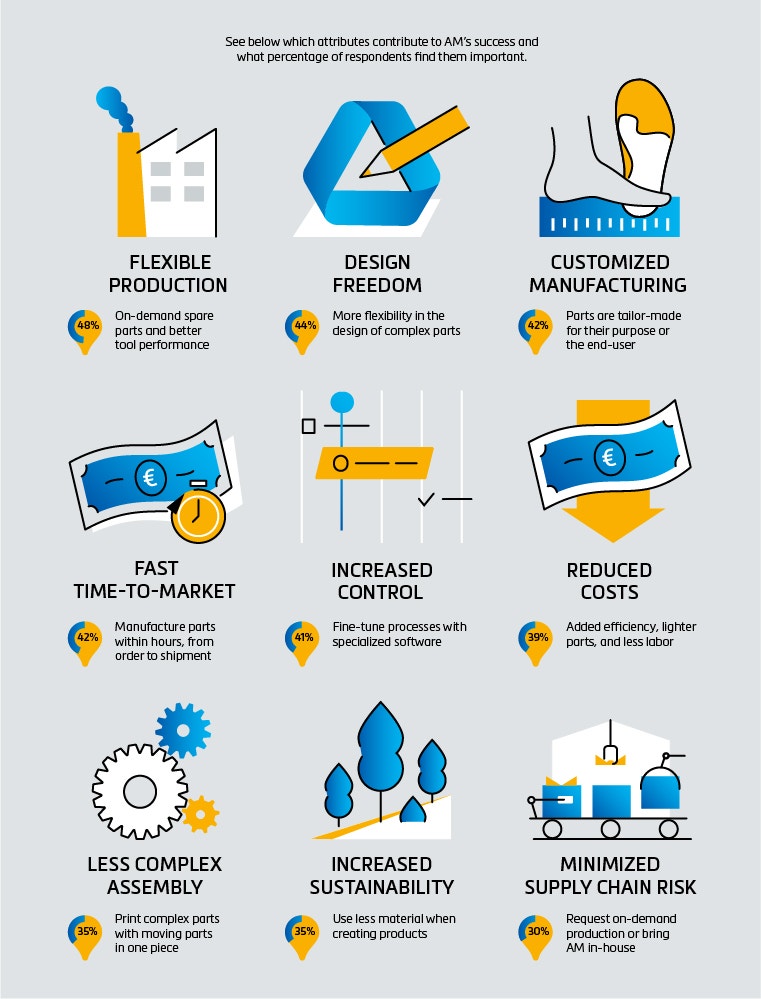

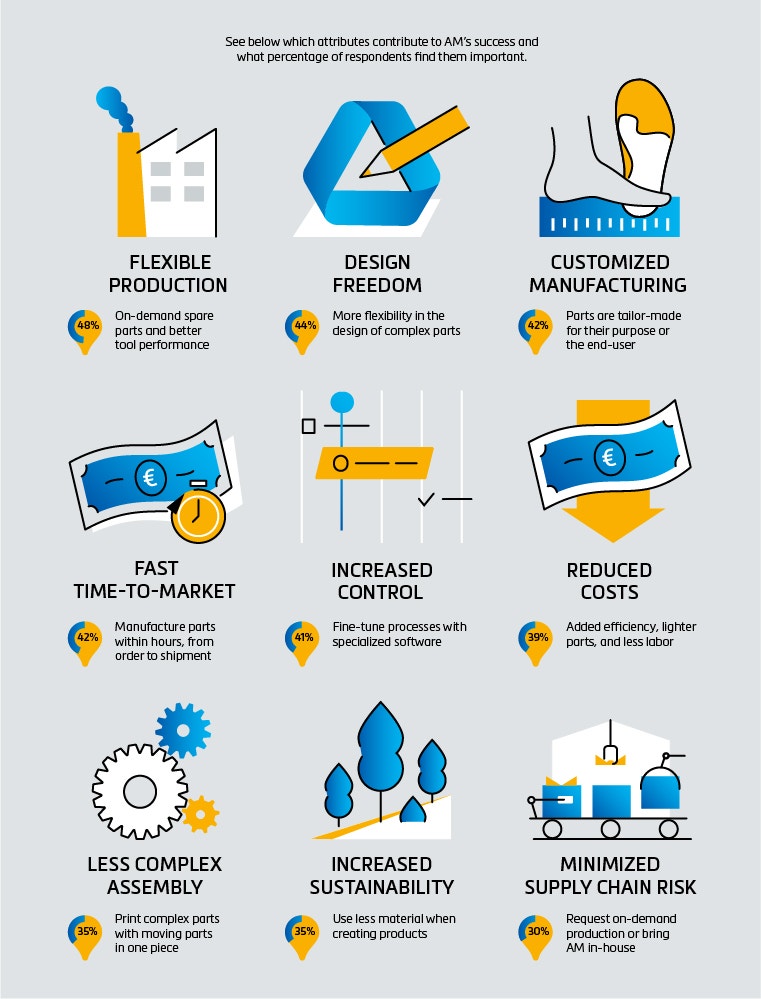

The value of AM

The companies seem to be on the same page when naming the most valuable attributes, with flexibility in production, design freedom, customization, and fast time-to-market agreed upon most often.

A turning point

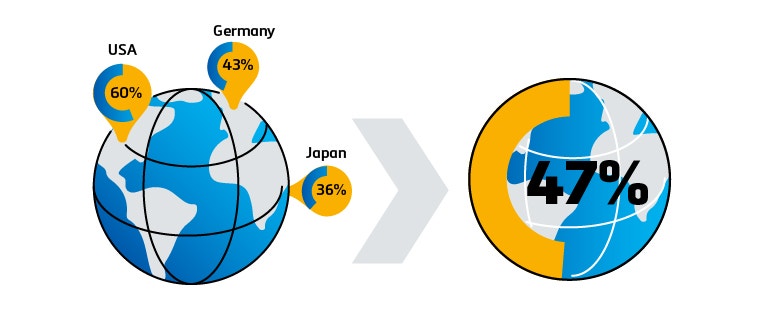

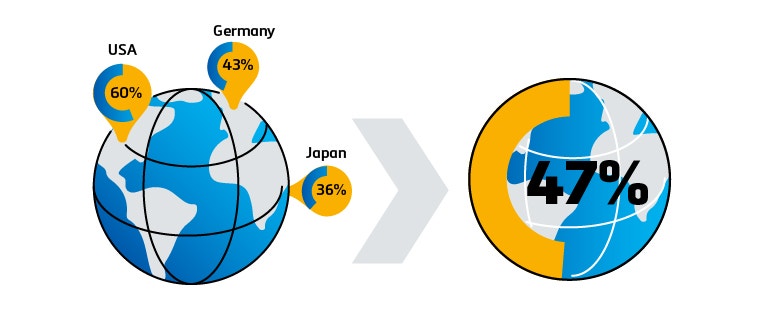

Up until now, companies have primarily used AM as a method to produce prototypes. However, we're reaching an inflection point where 3D-printed end-use parts are becoming more common. According to the survey, almost half of the respondents use AM for end-use production, with the US leading the way.

Requirements for AM suppliers

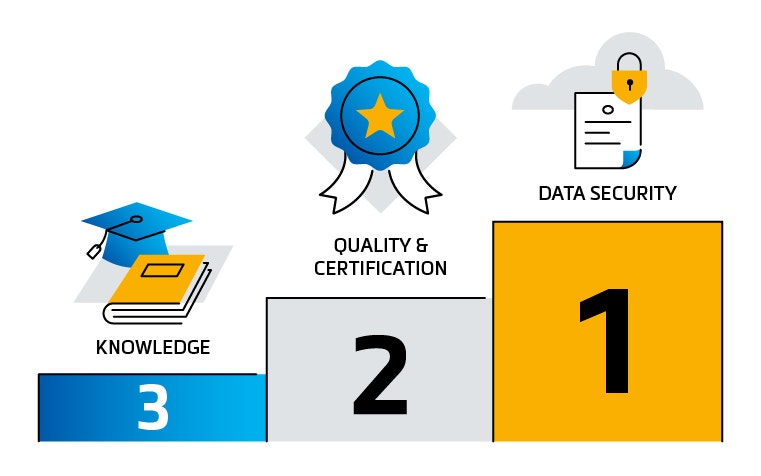

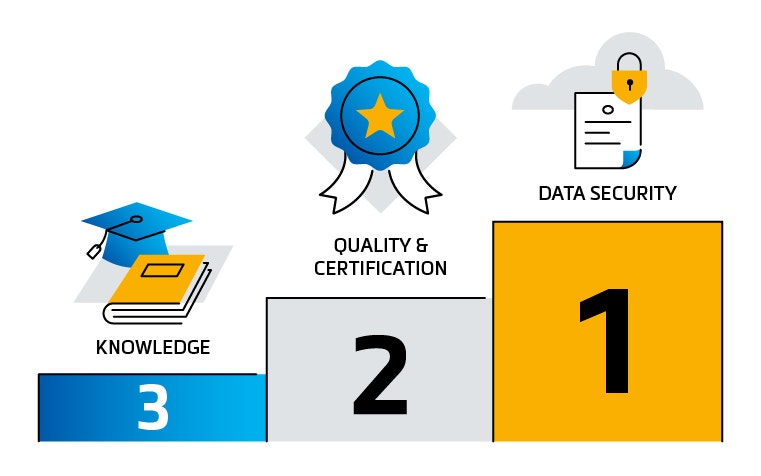

The survey also collected information on what these companies look for when choosing an AM supplier. Data security, quality processes and certifications, and AM knowledge lead the pack as primary requirements for a partner. These needs show that organizations are prioritizing reliable processes and results in their manufacturing. They may trust AM to add flexibility, cost efficiencies, and other advantages, but they need reassurance that their partners are dependable.

Data security is a factor we take seriously at Materialise. In 2022, we acquired Identify3D — a company that develops software to encrypt, distribute, and trace the flow of digital parts across complex supply chains — to add an extra layer of security to our CO-AM Software Platform.

Current adoption hurdles

Despite AM's undeniable benefits, companies still struggle to reach the finish line in the adoption journey because of various hurdles. In fact, 80% of respondents find that challenges such as quality issues and a lack of production efficiency are still present in their operations.

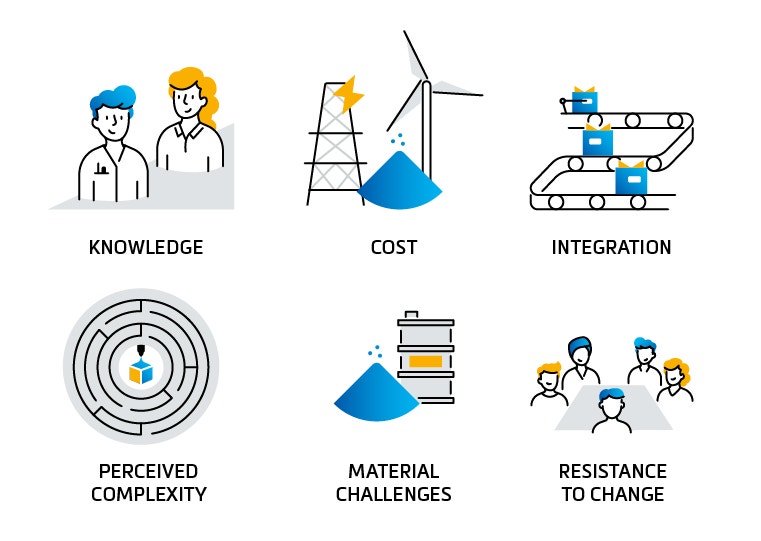

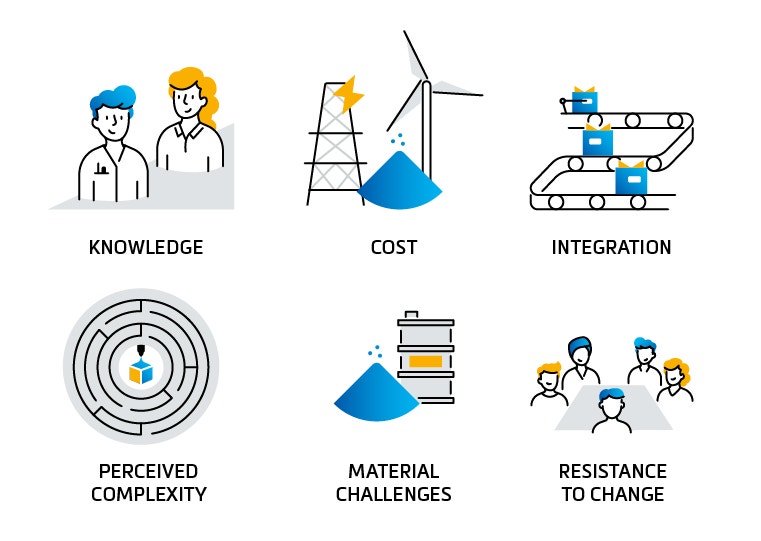

What holds companies back?

According to the survey results, it's quite clear what companies struggle to get right. Pinpointing these pain points gives us clear insight into the next steps. Here are the top six challenges and the solutions we suggest exploring to overcome them:

- Lack of knowledge: provide additional training and education — plenty of resources are available to hone AM skills.

- Costs: introduce easy-to-use software and hardware to boost efficiencies and reduce costs.

- Integration: you're not at it alone. Assistance from experts well-versed in AM integration will greatly simplify the implementation process.

- Perceived complexity: it's not as difficult as it may seem. Training and assistance are also crucial here to improve your understanding, such as guidance from AM consultants.

- Material challenges: the industry must aim to fix supply chains and introduce more AM-compatible materials.

- Resistance to change: educate decision-makers on AM's value and the best practices for integration.

Looking forward

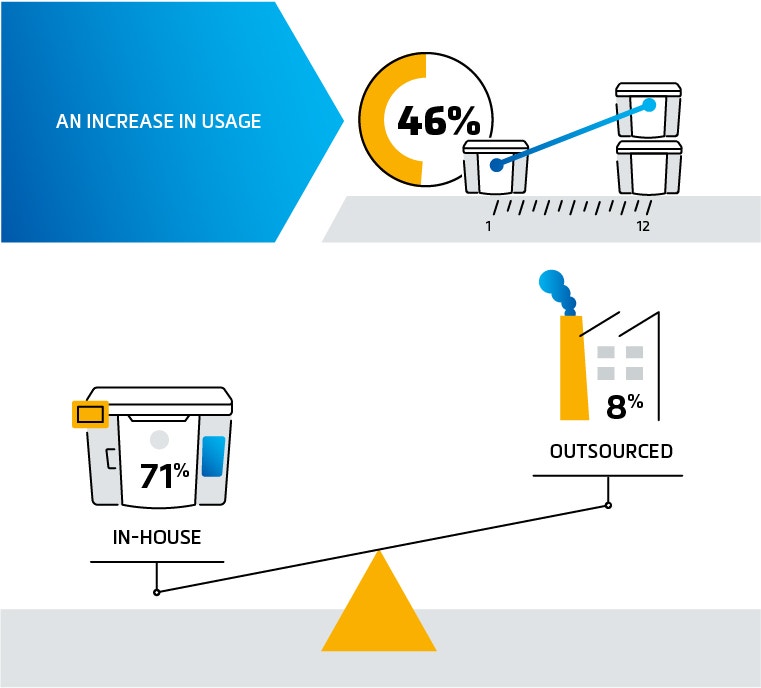

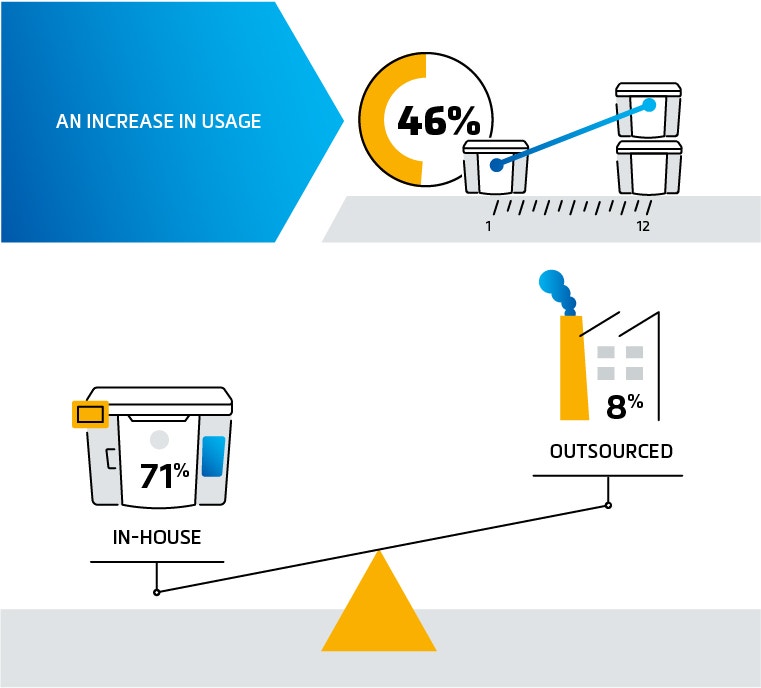

What's next for AM in the industry? The survey found that 94% of respondents plan to expand their use of AM in the next 12 months. Furthermore, 46% say that their use will at least double, and these expansions are trending towards in-house additive manufacturing — 71% plan to grow their own capabilities, while just 8% plan to outsource more.

Additionally, we identified a trend that we are very familiar with ourselves at Materialise: sustainability. It's not the highest on companies' lists yet, but respondents shared that they would like more sustainable AM options to help them reach their environmental, social, and governmental commitments.

At Materialise, we've made sustainability one of our top priorities, regularly completing life cycle assessments of our products, cutting our carbon footprint, and innovating to further reduce waste.

Where are you in your AM adoption?

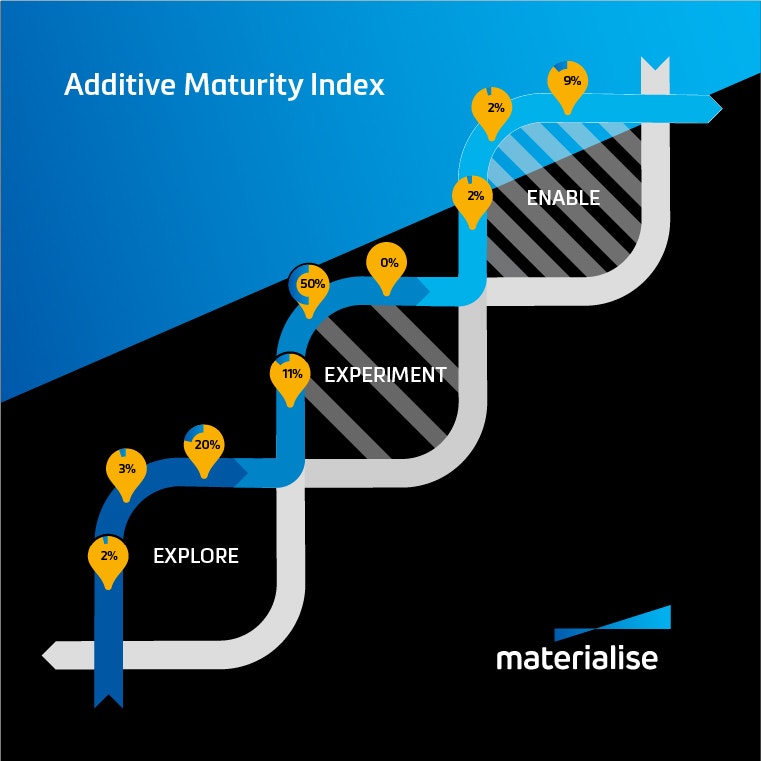

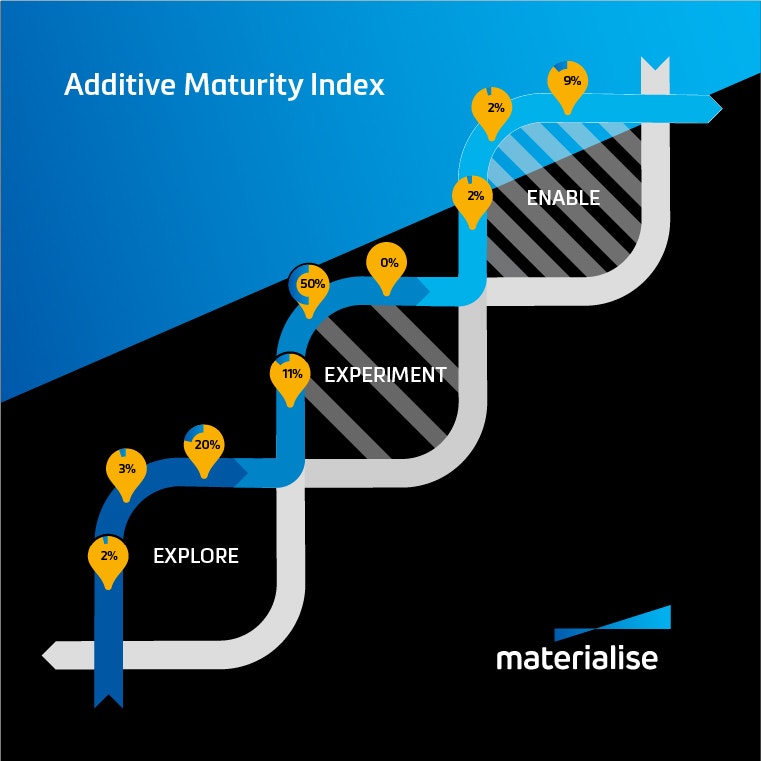

Our consultancy team ran these survey responses through their AM Adoption Assessment to determine the companies' positions along our nine-phase AM adoption journey.

With the conclusions drawn from this data, we launched the first annual Additive Manufacturing Index, which indicates the current state of AM adoption in the manufacturing industry. Results showed that half of the respondents are at the stage where they should begin assessing the feasibility of their projects. Based on these answers, we see that more than half of the respondents actively use AM but still have steps to take them further in their adoption journeys.

Share on:

You might also like

Never miss a story like this. Get curated content delivered straight to your inbox.