CUSTOMER STORY

Innovation in CMF Surgery: Personalized Solutions Transforming Patient Outcomes

Cranio-maxillofacial (CMF) surgery has seen remarkable advancements in recent years, primarily driven by the integration of personalized, 3D-printed solutions. These innovations have radically changed how surgeons approach complex reconstructive procedures, offering tailored solutions that enhance surgical precision, reduce operating times, and improve patient outcomes. With these advanced technologies, CMF surgery is now more adaptable and efficient, addressing traditional challenges with unprecedented accuracy and customization. Here, we explore some impactful cases from a recent webinar that illustrate the transformative power of personalized, 3D-printed solutions in CMF reconstructions.

Improving accuracy at APHP-Pitié-Salpêtrière Hospital

Since 2012, the introduction of personalized 3D-printed solutions at APHP-Pitié-Salpêtrière Hospital has helped the CMF surgical team overcome common challenges like shaping and positioning plates, long operating times, and donor site morbidity.

With 3D-printed guides, for example, the team has found excellent positioning when placing bone fragments and wanted to quantify that accuracy. To do so, they compared the angulation between each segment and the intercondylar distance in a series of patients. The control group was operated on with just cutting guides, while the test group's operations included the full personalized workflow, including pre-drilling guides, cutting guides, and personalized plates. Their findings showed that the accuracy for the test group was twice as high as the control group. They also experienced a significant reduction in operation time, for which they couldn't share conclusive results because the surgical steps differed greatly between the two groups. However, these findings were later confirmed in other studies.

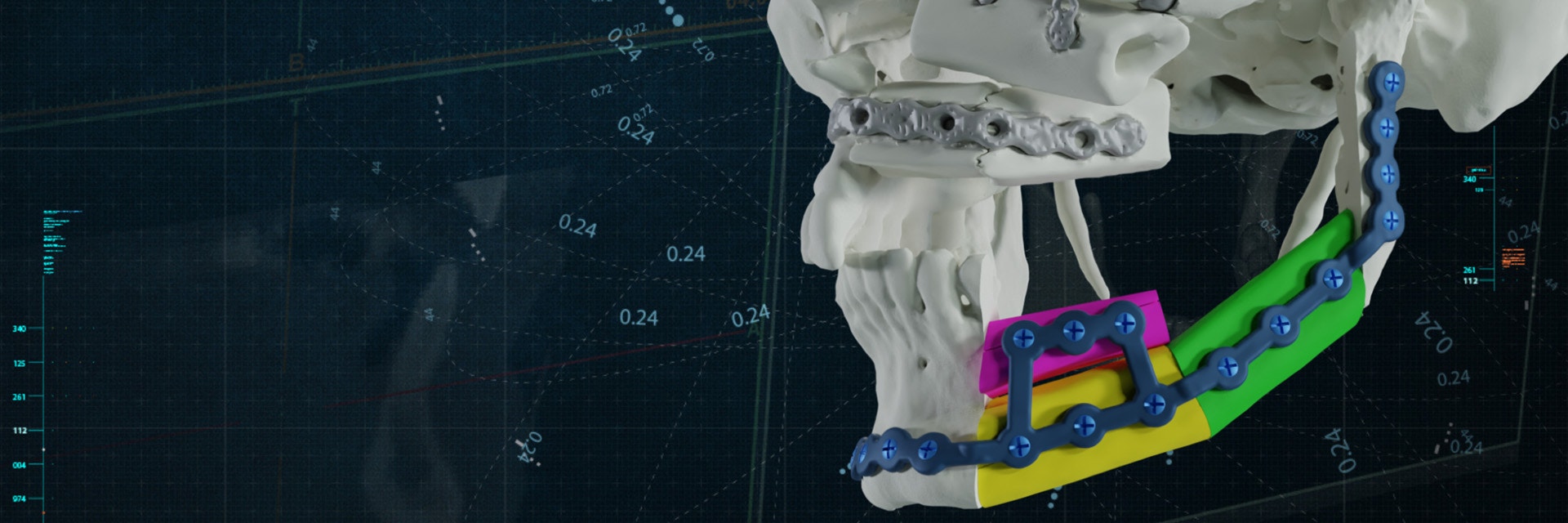

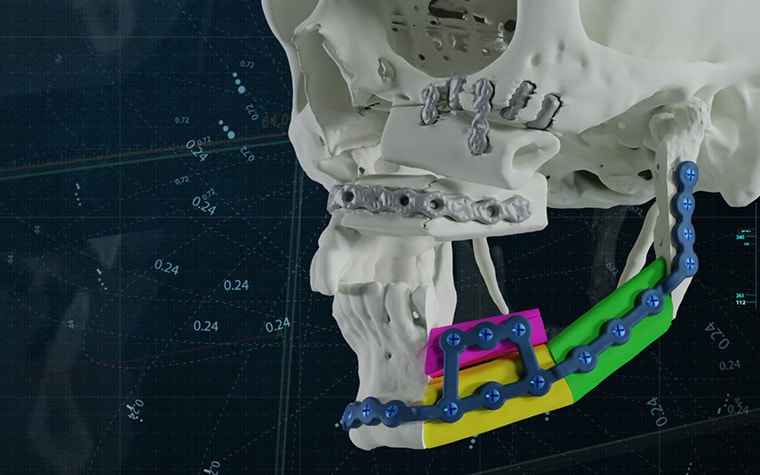

To further illustrate the benefits of personalized solutions, CMF Surgeon Prof. Thomas Schouman highlighted one noteworthy case involving a patient with an asymmetric mandible caused by previous oncology surgery and radiation therapy. This reconstruction required repositioning the mandible and utilizing personalized 3D-printed fixation plates, the flexibility of which allowed for modifications in implant design, such as the thickness, and intra-operative changes. For instance, Prof. Schouman pre-planned two resection options and seamlessly adjusted to the more suitable one during surgery once he was able to assess the tumor's growth since the CT scan.

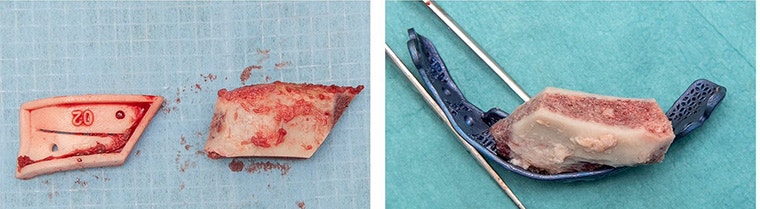

3D planning for personalized mandibular repositioning using 3D-printed surgical guides (left) and patient-matched plates (right).

Based on these outcomes, the CMF team at APHP-Pitié-Salpêtrière Hospital has implemented a strategy that helps them determine which approach to take. The personalized approach with these plates offers more accuracy and faster surgical times — meaning that it's typically their preferred method.

New treatment options at Erasmus MC

Next to speak on her experience with personalized CMF solutions was Dr. Hetty Mast, a CMF Surgeon and Head and Neck Oncologist at Erasmus MC in the Netherlands. When Dr. Mast started at the hospital in 2012, she was trained in bending standard reconstruction plates. Over time, the department has adopted personalized alternatives, with patient-specific milled plates entering the practice in 2014 and patient-specific, 3D-printed plates making their debut a few years ago.

"In our experience, the patient-specific printed plates have a faster production time," says Dr. Mast. "This is important for our oncological cases in the Netherlands, where our guidelines require us to begin treatment within 30 days after a patient's first visit to a clinic. Plus, printed plates have a more personalized design, which is especially helpful if you don't have a lot of bone for bigger plates."

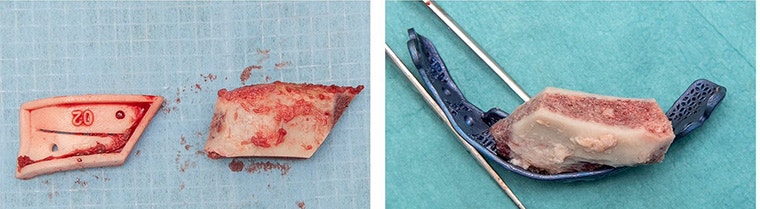

Dr. Mast walked the audience through three cases that demonstrated these benefits, one of which was for a patient with a smaller defect. In these cases, they don't need a free flap for reconstruction and instead use a non-vascularized iliac crest. However, for a better contour of the lower border of the mandible, reconstruction, a patient-specific reconstruction cage is ideal.

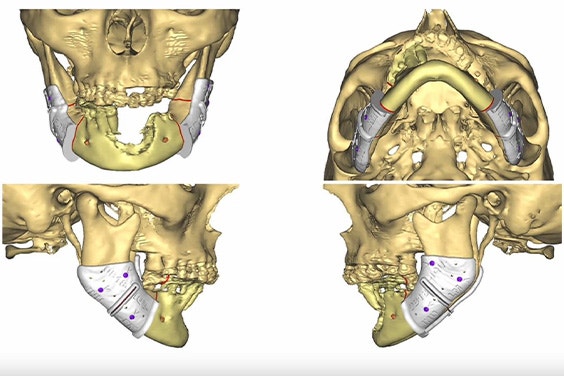

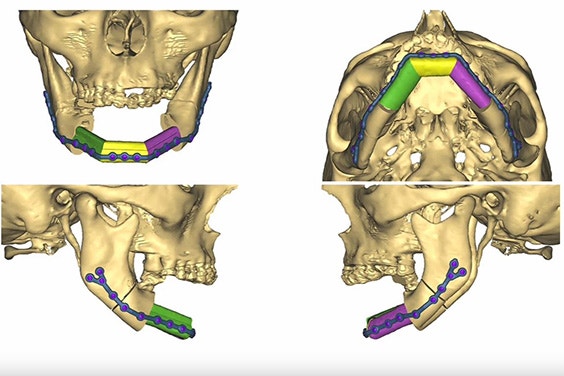

Dr. Mast's colleague Dr. BP Jonker and his research team published a paper on semi-automated digital workflows for these 3D-printed cages. This study demonstrated that their strength is equal to that of the mandible and that they are, therefore, suitable for use in patients. Since 2022, their team has used these specific implants, manufactured here at Materialise, in four cases. One patient had a dehiscence, requiring a follow-up operation, but all four patients now still have these implants in place.

One case in particular was a young man who lost a large portion of his mandible. After losing the anterior part of a scapular free flap reconstruction due to infection, they had to remove the milled reconstruction plate. They then planned a secondary reconstruction with the bone of the iliac crest within a personalized, 3D-printed titanium mandible cage. "We put the mandibular cage with the mandibular bones in place and filled the little gaps with bone scraping for the iliac inner cortex," explains Dr. Mast. "We found a better projection of his chin, and thanks to the smooth contour of the mandibular cage implant, this patient is now dentally rehabilitated."

Reducing operation time at AO San Camillo-Forlanini

The webinar wrapped up with insights from Prof. Bruno Andrea Pesucci and Dr. Flavio Andrea Govoni from AO San Camillo-Forlanini Hospital. In their CMF department, they integrated computer-aided design and manufacturing (CAD-CAM) into their surgical preparation some years ago and have worked closely with companies like Materialise ever since to test out new approaches to personalized treatment.

"We've worked with many companies but arrived at the end with, I think, the best company: Materialise," explains Prof. Bruno Andrea Pesucci. "They support our work with new concepts and study them alongside us. We are very satisfied with our work with Materialise throughout the years."

Dr. Flavio Andrea Govoni continued to highlight the case of a patient with a giant, aggressive, ossifying fibroma of the mandibular body. In collaboration with a Materialise clinical engineer, they planned the osteotomies and reconstructions via CAD-CAM techniques, and with the personalized guides, they were able to reduce time in the operating room and easily achieve an accurate fit of the fibula flap. They were very pleased with the results, too, achieving good functional and cosmetic results. Plus, the thin plate allows for low-risk radiotherapy if needed.

We've seen the introduction of personalized, 3D-printed solutions greatly advance CMF surgery over the years, addressing traditional challenges and enhancing surgical precision. We strongly believe that this is the direction in which the field will continue to grow, promoting groundbreaking innovation and, most importantly, improving patient care.

L-104084-01

Share on:

You might also like

Never miss a story like this. Get curated content delivered straight to your inbox.