EXPERT INSIGHT

A Guide to 3D Printing Polyamides

What’s in a name? When it comes to polyamide, quite a lot. The numbers, the letters, the technologies — they all impact your final part’s characteristics, making it crucial to choose the right option for your project. And as it's a family with a lot of members, that decision can be a little daunting.

Luckily, this guide is here to help. We’ll dive a little deeper into each option, exploring their strengths and ideal applications, and explain the key differences between the technologies you can choose from: Multi Jet Fusion (MJF), fused deposition modeling (FDM), and selective laser sintering (SLS).

In this guide:

Technologies:

Materials:

Which 3D printing technology should I choose?

One of the first things you’ll notice when choosing a material is that polyamide is available for multiple technologies, including traditional manufacturing techniques. Which one you opt for will depend on the needs of your project. While it’s not always possible to define more than generalized differences between each technology, it’s important to know that the process does have an impact on part performance, with no two giving you the same result.

MJF is well-known for providing high-performance parts and short lead times. It stands out by printing components that tend to have a greater density than those made with SLS, partly due to a lower layer thickness, meaning it is likely to have better mechanical properties.

It’s a great choice for components that require the following attributes:

- Leak tightness

- Heat or electrical conductivity

- Low anisotropy

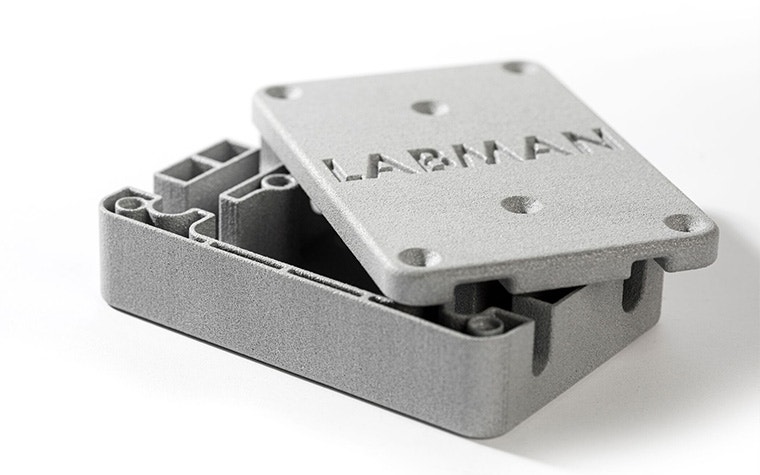

Where parts printed in MJF often have a slight edge in mechanical performance, SLS tends to better them in visual aspects. You’ll find a greater variety of finishing and post-processing options alongside similarly high precision and part performance, making it just as suitable for most prototyping and end-use parts.

Generally speaking, it’s a good choice if your project requires the following:

- Smooth, painted, or aesthetically pleasing surfaces

- Complex geometries

- Precise tolerances

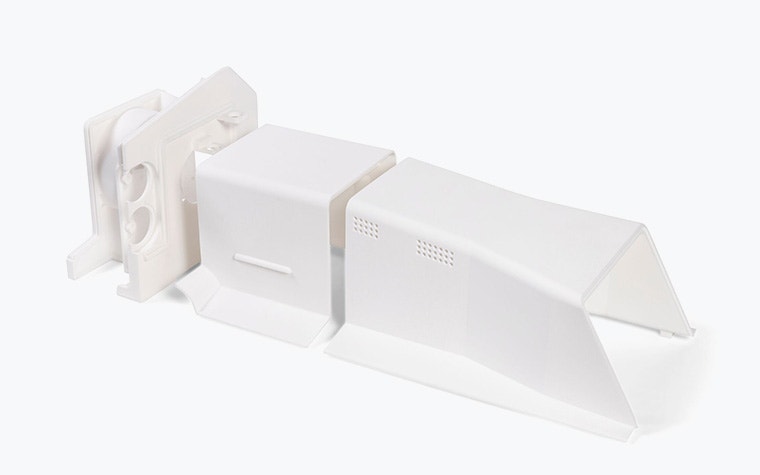

Unlike MJF and SLS, which are both powder bed technologies, FDM deposits melted material layer by layer upon a building platform. Given this change in approach, it’s understandable that FDM parts will have more noticeable differences than the others. At Materialise, you’ll have access to carbon-filled PA 12 (PA-CF), which is ideal for incredibly durable, lightweight components with excellent mechanical properties.

Unfinished parts do tend to have a rougher surface than with MJF and SLS, so if aesthetics are important, you’ll need to invest in one of the multiple post-processing options at your disposal. Naturally, we also offer other thermoplastics that deliver different benefits, but we’ll stick to the polyamides in this article.

Overall, it’s likely to be the best solution when the following requirements matter more than anything else:

- Strength and durability

- Stiffness

- Stress resistance

How do I choose a 3D printing material?

In all honesty, it depends on what you consider first; your options are automatically defined by the technology you choose, and vice versa. Having a deep understanding of exactly what your final part requires — whether in terms of characteristics or certifications — is, therefore, essential. Ideally, it’s information you should share in as much detail as possible when you first approach your 3D printing partner.

To help simplify your options, we’ve split our available polyamides into three groups, beginning with the niche or stricter requirements before branching out into the more traditional and well-known materials.

Flame-retardant polyamides

If flame retardancy is a mandatory characteristic for your part, your choice is simple: PA-FR. This polyamide contains a flame-retardant chemical and is compliant with CS/FAR 25.853. Those working in aerospace and aeronautics may be interested to know that it is also available in an Airbus-certified grade in accordance with AIPI 03-07-22.

It’s ideal for printing flame-resistant parts with excellent mechanical properties and has a wide variety of finishing options for projects where aesthetics are important.

Filled polyamides

When you need strong, durable parts, it’s hard to look past filled polyamides, and few can compare to carbon-filled PA 12. This solid, stiff, and lightweight thermoplastic is reinforced with carbon fiber, giving it the highest flexural strength and stiffness-to-weight ratio of any FDM material — and making it twice as strong as regular polyamide.

These characteristics make it ideal for applications such as tooling, functional prototypes, and machine parts that undergo regular stress.

Merging polyamide with aluminum, PA-AF produces parts with clear characteristics of each material: strong, stiff, and heat resistant up to 130°C, and a metallic appearance that makes it ideal for models, tooling, and fixtures.

Sitting somewhere between traditional PA 12 and PA-AF in terms of characteristics, this glass-filled polyamide offers high durability, stiffness, and thermal resistance up to 110°C. It’s ideal for functional prototypes and rigid end-use parts, especially those used in demanding environments where temperature and wear resistance are key.

Traditional polyamides

When it comes to naming materials — especially the traditional polyamides, PA 11 and PA 12 — it can be helpful to start by explaining what the numbers mean. In this case, it refers to the number of carbon atoms in the monomeric unit. This is just one of the factors, alongside particle or layer size, and additives like antioxidants and flowing aids, that influence the characteristics of each variant.

Perhaps the most commonly used 3D printing material, PA 12 is well-known for its stability, chemical resistance, and strength. While its mechanical properties will be slightly lower than PA 12 for MJF, this combination of material and technology will provide better surface properties alongside a greater selection of finishing options.

Just like its counterpart in MJF, it’s an ideal option for functional prototypes, end-use parts, and consumer goods.

If mechanical performance is more important to you than aesthetics, a combination of PA 12 and MJF is likely to be your best option — though surface quality won’t disappoint here, either. Low porosity, near-isotropic mechanical properties, crisp textures, and detailed surfaces make this all-round material a regular favorite.

With a higher density than laser-sintered polyamide, this strong, general-purpose material is ideal for precision forms and works equally well for functional prototypes or end-use parts.

For projects where looks, speed, and price are essential, you can’t go wrong with PA 12S. Its winning combination of high visual specifications, excellent dimensional accuracy, ample mechanical performance, and low post-processing requirements make this polyamide a versatile alternative for a wide range of projects.

It’s an ideal choice for fast iterations during prototyping or low-requirement series production.

This material is somewhat unique among polyamides in that it offers the high strength and stress resistance of PA 12 with lower stiffness and higher elongation. When combined with its impressive surface quality and detail, you get an option that’s ideal for both series production and functional prototypes.

Since adding PA 11 to our portfolio, it’s proven particularly popular in industries such as medtech, aerospace, and automotive.

Help is always on hand

Understanding the different polyamides is a great start to finding the right one for your project. Of course, every project is different; there’s no one-size-fits-all. Whether you prioritize costs, mechanical performance, aesthetics, or some combination of them all, your project’s requirements will define which technology and material is best for you. Going into every project with an open mind and finding a partner who can give you honest and unbiased advice is key. They’ll always want you to succeed and deliver the best results.

At Materialise, that’s something we pride ourselves on. We’re a technology-agnostic company, meaning we have no preference for one solution over another. For more than 30 years, we’ve built a deep working knowledge of every option, and we’re thrilled to share that with our customers.

So, if you’d like to tell us more about your project or learn more about your choices, don’t hesitate to reach out. We’re always happy to help.

Share on:

You might also like

Never miss a story like this. Get curated content delivered straight to your inbox.