EXPERT INSIGHT

Expert Workflow Just Got Better: Introducing 3D Scan Images Import Option

As you may know, RSscan included 3D scanners to their portfolio already a few years ago, adding 3D static data to complement the dynamic pressure measurement to design custom orthotics. This spring, in the upcoming footscan9 software update, we are including the option of importing your own STL and OBJ files into the database.

Relevant tendencies in the market instigated this specific feature. Public and private health care institutions might request a 3D image for reimbursement reasons. 3D scan import also makes it easier to combine both 3D imaging and dynamic pressure measurement in one software environment. Additionally, clinicians use 3D imaging to compare the static 3D image to the design suggestions generated by the dynamic pressure analysis.

However, at the core of every innovative solution we design, lies our wish to understand the human foot and human kinetics better. Considering the importance of improved and more individualized measurements to ensure optimal comfort and fit, our mission is to keep improving our offering and to provide clinicians with better tools for both analysis as well as design for orthotic applications.

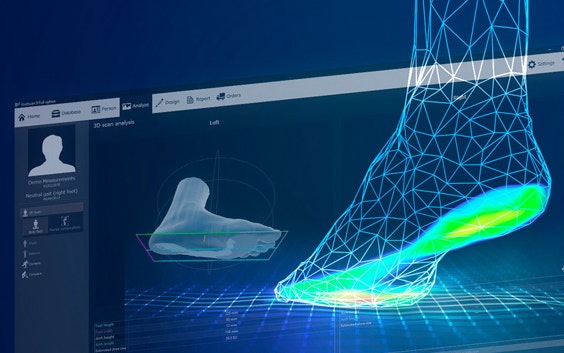

Following this objective, in the latest footscan9 software update, we added the possibility to integrate external 3D imaging to dynamic footscan pressure measurement data. This means, that starting from April 19, you will be able to import your STL and OBJ files into the footscan database. In the research1 conducted by Antwerp and Utrecht Universities, the goal was to identify foot shape abnormalities and link the prevalence of specific foot pains to foot shapes through advanced statistical models. To obtain the data, they used a Tiger 3D scanner, and a footscan pressure plate and worked closely with our R&D team. The value of this research project is in combining and analyzing data obtained from multiple sources. At Materialise, we aim to find the correlations between dynamic pressure measurement and static 3D imaging. These insights will enable our R&D teams to develop unimaginable 3D print orthotics designs, offering clinicians worldwide the best possible digital workflow.

Adding another dimension for optimized results

As an all-inclusive package for the clinician’s workflow, Materialise Phits Suite takes care of all the steps in creating the 3D printed orthotics, from data capture, and analysis to designing and manufacturing the 3D printed orthotics. Until now, our digital expert workflow supported only 3D images with the iQube mini, iQube, and the Tiger.

By introducing and enabling the import of any 3D file (STL, OBJ) into the footscan9 software, we want to offer a more flexible solution for healthcare professionals worldwide. The 3D scan images import feature brings various benefits, the main ones being:

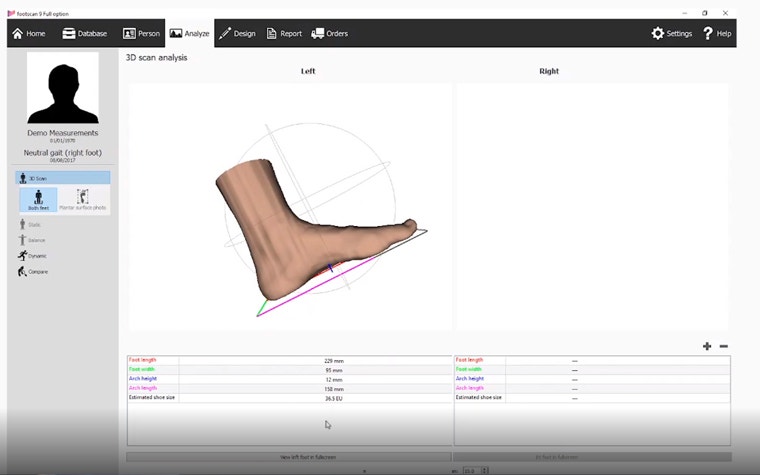

- integration of 3D volumetric data, and more specifically the navicular height calculated and visualized in the design wizard which can be used by the clinician to manually adapt the Phits insole design

- depending on the 3D scan, the clinician will be able to calculate foot length, foot width, arch height, and circumferences to design an orthopedic shoe

- storage of dynamic pressure measurement and 3D scan images (volumetric data of feet, plaster casts, lasts, or even foam boxes) together in one client database.

Power up your process with our 3D scanners

In case you are still considering which 3D scanner is the best for your practice, two models included in our Materialise Phits Suite deliver flawless results without technical hurdles: Tiger 3D scanner and iQube series.

Tiger 3D Scanner helps you create a complete and detailed 3D scan of your subject’s foot. Captured up to above the ankle, the Tiger allows you to perform additional analysis on the shape and form of the feet. Thanks to nine cameras, this scanner will give you an automated foot calculation, arch height, foot length, foot width, and accurate gait measurements. The output is automatically visualized in the footscan software.

iQube scanners in our suite are iQube E100 Mini and iQube E500 models. While the Mini one has only one camera, it’s a perfect portable solution to capture foot data quickly, be it at the patient’s home or in different clinical locations. The E500 model has 5 cameras that capture accurate data of the patient’s foot, providing more accurate volumetric data than the E100 Mini.

[1] Subject-specific identification of three-dimensional foot shape deviations using statistical shape analysis (Kristina Stankovi ´c a , ∗, Toon Huysmans a , b , Femke Danckaers a , Jan Sijbers a , Brian G. Booth a a imec - Vision Lab, Department of Physics, University of Antwerp, Antwerp, Belgium b Section on Applied Ergonomics & Design, Department of Industrial Design, Delft University of Technology, CE Delft, the Netherlands) Crosshead

Share on:

You might also like

Never miss a story like this. Get curated content delivered straight to your inbox.