EXPERT INSIGHT

A New Legacy for AM: Empowering the Choice for Sustainability

The past three decades have seen additive manufacturing mature into an innovative technology. Then, with the COVID-19 global health crisis, the benefits of the technology — making urgently needed products faster and locally — became meaningful in a new way. As we enter the fourth decade of 3D printing, let us look at how innovation can empower sustainability and rethink not just what it allows us to make, but what it makes possible.

Over the past 30 years, 3D printing has gone from being the new kid on the block to a revolutionary technology, capable of transforming entire industries and challenging conventional manufacturing processes.

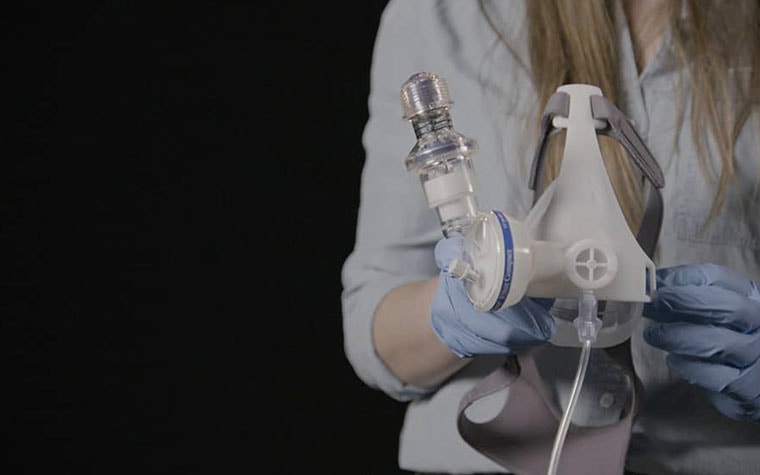

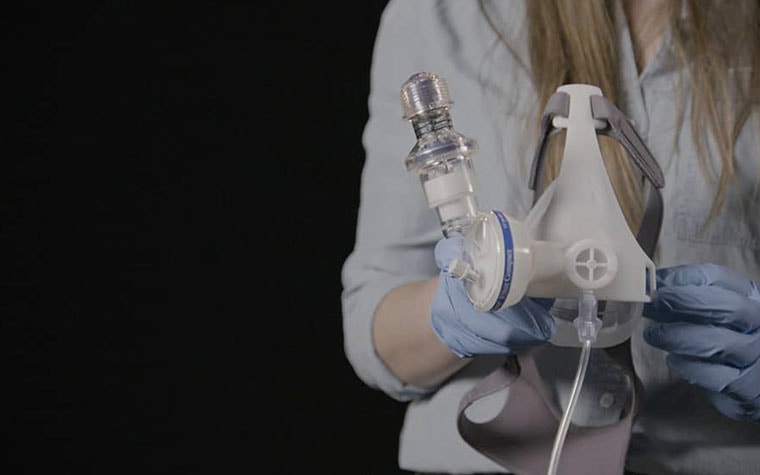

More recently, following the outbreak of the COVID-19 pandemic, the technology was put to the test. Global supply chains were disrupted, and solutions to support healthcare workers and COVID-19 patients were urgently needed. From decentralized manufacturing to expanded design processes to faster iterations and overall increased speed — the benefits of 3D printing became tangible and more meaningful within these new circumstantial parameters.

Today, as accelerated digitization ushers in a decade of potentially radical innovation, we ask ourselves: how can AM be meaningful in the fourth decade of 3D printing?

Making things differently to make a difference

At Materialise, we believe that AM is meaningful when it empowers people to make better choices. As we enter the fourth decade of 3D printing, there are two fundamental choices to be made.

The first is the choice to challenge the status quo by doing things differently.

With the onset of the COVID-19 pandemic, companies experienced the vulnerabilities that resulted from relying on overseas suppliers. Healthcare professionals, as well as average consumers, were confronted with shortages and quality issues with both essential medical products and everyday goods — a consequence of a global market model that hinges on centralized mass manufacturing.

The consensus seems to be that returning to business as usual would imply a ‘new usual.’ We have seen that nations are rarely self-sufficient, we have felt the need to fix our supply chains, and we want to become more customer-centric. In other words: we need to do things differently.

In the early days of the ongoing health crisis, AM stepped up as an alternative manufacturing technology, a different technology that was used to make the same product faster, more cost-efficiently, and locally. But its core strengths go beyond these benefits. AM frees designers from the constraints and limitations of traditional manufacturing technologies, helping them to focus on the solution instead of the product.

What can we do to make AM more sustainable?

There’s a second, equally important choice to be made: the choice for sustainability. This means reducing waste and costs while producing responsibly.

AM is often considered a more sustainable manufacturing technology: because it’s additive and thus generates less waste, it enables local production and higher-quality jobs, and it enables more personalized solutions and reduces global trade. In fact, a survey by Materialise indicates that 85% of manufacturers find that 3D printing is a more sustainable way to manufacture products when compared to conventional manufacturing technologies.

But does AM really serve our drive toward a more sustainable society? Are we not simply surfing on a trend, greenwashing the technology?

BASF and Materialise recently compared the environmental impact of three 3D printing technologies with a conventional manufacturing technology for the production of one million pairs of midsoles. This lifecycle analysis (LCA) indicated that for large series of identical products, 3D printing is currently not the most sustainable choice and has a bigger impact on climate change and the depletion of fossil fuels compared to conventional manufacturing technologies.

Just as the Corona crisis forced industries to shift gears, the climate crisis is an existential threat, and addressing it comes with a sense of urgency that doesn't allow us to advance in incremental steps. It requires us to drastically rethink the way we develop solutions — and not simply build on existing technologies. In such an incremental innovation process, there is often little room for AM.

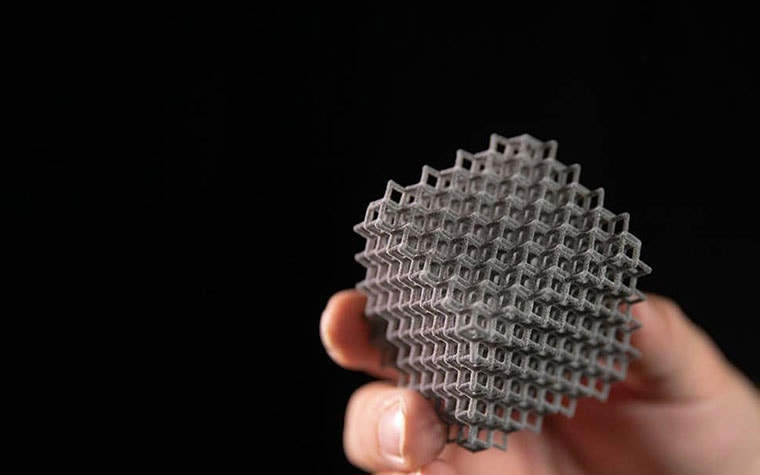

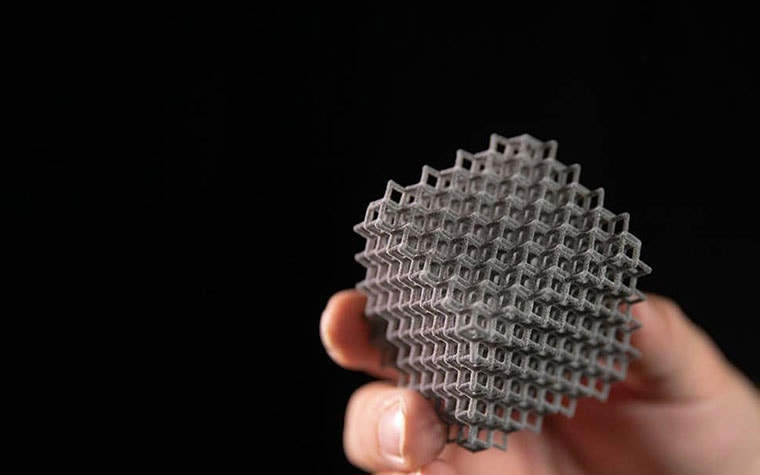

But as companies answer the call to drastically rethink their innovation cycles, to skip incremental steps and make giant leaps ahead instead, they start to reimagine designs and create room for bold new ideas. Such a climate of radical innovation creates opportunities for AM

At Materialise, we believe that the choice for sustainability will become essential in the next decade — and we want to empower that choice. To do so will require us to embrace an innovative mindset ourselves. Because the question is not whether AM is a sustainable manufacturing technology. The question becomes: “What can we do to make AM more sustainable?”

Empowering the choice for sustainability

The introduction of Bluesint PA 12 is an example of how we empower our customers’ choice for sustainability. Bluesint PA 12 makes it possible to print with up to 100% re-used powder, drastically increasing the resource efficiency of laser sintering. Over the course of 2021, Materialise plans to have several laser sintering machines running with Bluesint PA 12. In the start-up phase alone, the company aims to reuse more than five tons of powder that would normally become waste. Creating a path towards eliminating waste in the 3D printing process is a great example of what we can do to make AM more sustainable.

Planting the seeds of radical innovation

When we think from a bigger perspective, we truly innovate and create room for new technologies. Such a climate of radical innovation presents opportunities for AM. A post-Corona era may present the opportunity to build a better, healthier, and more sustainable future.

Share on:

You might also like

Never miss a story like this. Get curated content delivered straight to your inbox.