PATIENT STORY

Surgery Made Possible on “Inoperable” Spine Condition Thanks to 3D Technology

In 2021, we had the opportunity to meet Zoé Maldonado, a 14-year-old girl who suffered from a case of early severe idiopathic scoliosis. It was Dr. Hugo Vilchis Sámano — a Traumatologist and Orthopaedist specializing in spine conditions and Head of the Spine Department of the High Specialty Medical Unit in the Hospital of Traumatology and Orthopedics Lomas Verdes, Mexico — who came to us in search of a 3D reconstruction.

He specified that a 3D reconstruction could help him and his team improve the probability of success of Zoé’s case. After having undergone eight unsuccessful surgeries, Zoé needed a new intervention to recover lung capacity that had diminished due to the curvature of her spine to the point of incapacitating the young woman, who required a constant extra supply of oxygen. However, other specialists ruled out the case as it was considered inoperable.

With Zoé’s condition deteriorating at that time, the Florida Satellite Rotary Club and Dr. Vilchis, who had spent some years working together on a Corset Donation Program for low-income children and youth with scoliosis, sought a visionary technology that could help the young woman.

It was the perfect opportunity to unite experiences and talents to gain a better perspective on the case.

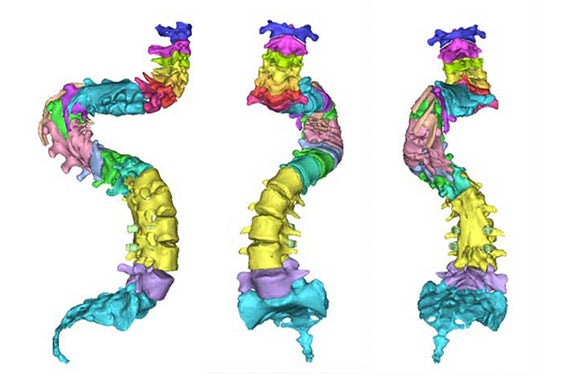

The 3D reconstruction of the spine was created from a tomography image using the Materialise Mimics Innovation Suite. Thanks to the power of our software, it was possible to achieve an accurate reconstruction, vertebra by vertebra, in a very short time. At the same time, Intelligy — a local Mexican company — 3D printed the column with Stratasys’ PolyJet technology, which solidifies resins using UV rays to form parts with microscopic layers and high precision. This ensured reproducibility from virtual to physical.

Left: Spine 3D reconstruction with MIS Right: Anatomical model printed with Stratasys

“By having a digital and 3D-printed model, we knew exactly what the patient’s spine was like.”

— Dr. Hugo Vilchis Sámano

Our technology allowed Dr. Vilchis and his team to plan the surgery and move forward with a case that had previously been considered inoperable.

“By having a digital and 3D-printed model, we knew exactly what the patient’s spine was like since both technologies reproduced every detail of its structure exactly. Two surgeries were performed using 3D technology. The first, with the objective of placing screws and bars, was successful as no errors were made and the time in the operating room was reduced by 40%,” commented Dr. Vilchis.

The second surgery was the most complex. Its objective was to remove vertebral bodies to eliminate the curvature of the spine as much as possible. “It was in the second intervention when we faced a great challenge — the spinal cord stopped working, which would imply that the patient could suffer damage to her mobility. We worked for three hours trying to rescue the cord. We succeeded in the end, but there’s no doubt — it would have been impossible without the 3D model,” said Dr. Vilchis.

Dr. Vilchis and his team have set a precedent in Mexico, being pioneers in the use of digital and 3D-printed anatomical models for surgical planning in highly specialized cases. They also appreciate the support of the Florida Satellite Rotary Club for co-funding these technologies and making their use possible. They hope to continue using them in their scoliosis program.

Once again, personalization in healthcare shows that it can enhance people’s lives. We must continue working to make it possible for everyone, thus becoming the new standard of medicine.

Mimics medical and 3-matic medical do not classify as medical devices that need registration in Mexico.

L-102666-01

Share on:

You might also like

Never miss a story like this. Get curated content delivered straight to your inbox.