CUSTOMER STORY

Unleashing the Potential of AM for Low-Criticality Aircraft Parts

Over the last five years, additive manufacturing (AM) has matured considerably as a manufacturing technology, with evolving value chains and innovations pushing it into the mainstream arena. While industry conversations often focus on printing safety-critical metal parts, aircraft manufacturers and MROs are starting to see the real potential in using 3D printing for low-criticality or no-criticality plastic components, especially as decentralized and on-demand manufacturing is becoming more attractive than ever.

No longer seen as merely a tool for rapid prototyping, the emergence of 3D printing as a future-proof way to produce smarter, cheaper, and more performant end-use parts means that AM has firmly made its way into boardroom conversations across industries and around the world.

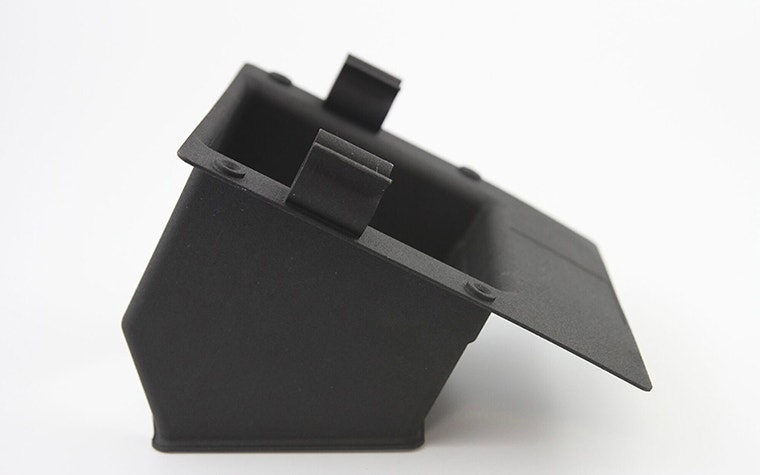

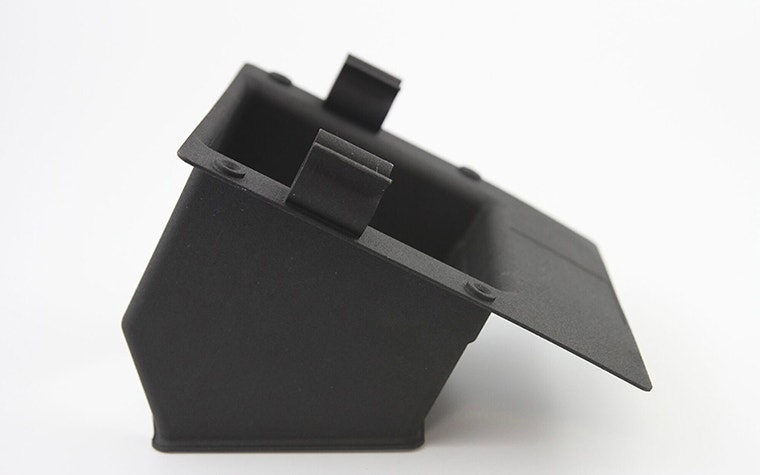

Within the field of aerospace, applications of 3D printing technology are diversifying considerably — from structural components where function is king, such as GE’s LEAP fuel nozzle (a walnut-sized part that was one of the most disruptive pieces of technology in GE history), to aircraft cabin interiors like that of Airbus where elements need to be both functionally and aesthetically perfect.

The 3D printing of low-criticality plastic components has matured rapidly in recent years. As an EASA 21.G-certified production organization, Materialise currently manufactures an estimated 26,000 3D-printed parts per year across the Airbus A350 ecosystem alone in its certified manufacturing facility. Yet, despite the obvious benefits, the full potential of additive manufacturing for the aerospace industry as a whole is still far from being realized. So, why is adoption not more widespread?

Towards an easier qualification path for low-criticality parts

The most commonly voiced challenge to using AM for flight-ready parts is that of qualification. The wide variety of options and flexibility that make 3D printing such an attractive solution for flight-ready parts are also what make it so difficult to determine a qualification path.

Recognizing both the barriers and the huge potential of AM, civil aviation authorities have shown their willingness to support an easier qualification path for low-criticality parts and encourage a more collaborative approach across the industry. In November 2020, following considerable dialogue with the industry, the European Union Aviation Safety Agency (EASA) published an updated certification memorandum that provides guidance on the introduction and use of AM technologies across a broad range of aerospace products, parts, and appliances, and highlighted low-criticality parts for the first time.

In making way for a certification approach that is proportional to criticality, EASA has given the green light to the European aerospace industry to take full advantage of the benefits that AM offers for manufacturing low-criticality parts.

Reducing costs and risk through on-demand manufacturing

In an industry where production volumes are often low, 3D printing’s tooling-free technology makes small-series manufacturing considerably more affordable than conventional manufacturing where cost per part is much more dependent on volume. Even with temporarily fluctuating demands, manufacturing can simply be scaled as needed.

This reliance on a digital inventory rather than a physical inventory — with the associated overstock risk and warehousing costs — drastically reduces supply chain concerns and means 3D-printed spare parts can be delivered with ultra-short lead times. What’s more, with parts easily available on-demand, there is much more opportunity to tweak and improve a part over time, e.g., to make it lighter, more performant, or correct a weakness.

Finding the sweet spot for AM

More and more flight-ready parts are being routinely manufactured by certified AM suppliers like Materialise as aerospace manufacturers and MROs discover how the benefits of 3D printing can help them gain agility and flexibility in their supplier set-ups. But for those exploring AM for the first time, knowing which applications to manufacture with AM to achieve peak efficiency and cost benefits can seem daunting.

Our whitepaper, ‘Sourcing Low-Criticality Parts for Aircraft’, produced by the aerospace team at Materialise, gives an overview of the supply chain opportunities and advantages of using AM to manufacture low-criticality plastic parts. The paper also provides benchmark data and practical guidance on implementing AM in your supply chain.

Share on:

You might also like

Never miss a story like this. Get curated content delivered straight to your inbox.