EXPERT INSIGHT

3 Tips for 3D Printing Companies Looking to Reduce Their CO2 Emissions

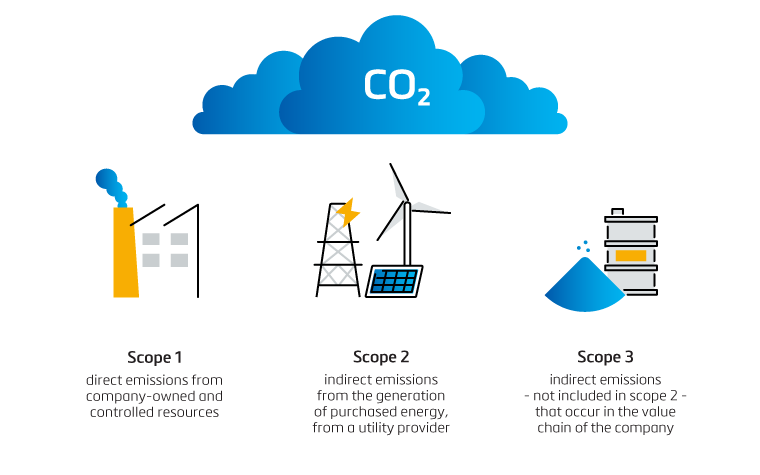

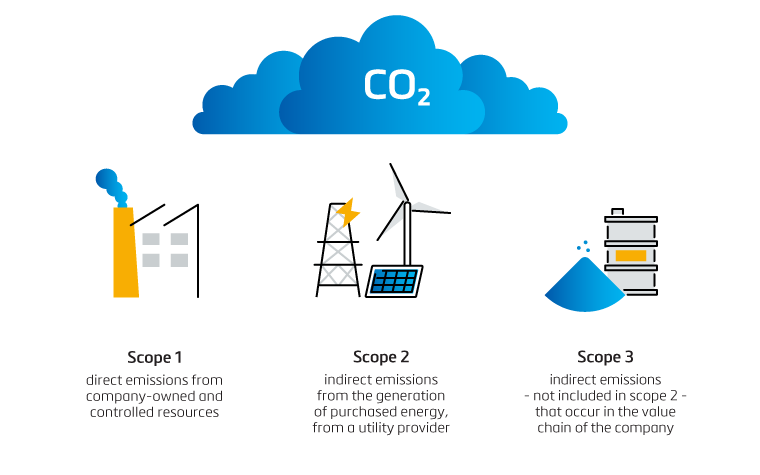

In theory, every business knows the importance of reducing their greenhouse gas (GHG) emissions. However, in practice, getting started can seem rather daunting. Should you target emissions in scope 1, 2, or 3, and what do they mean? How long will these initiatives take to implement? And how can you get your workforce onboard? We’ll answer these three questions and show you how to achieve some quick wins to get your sustainability goals on track.

To create a better and healthier world, all businesses must play a significant role in combatting climate change by cutting their GHG emissions. At Materialise, we’ve found that using a three-tiered approach — reducing, innovating, and collaborating — is guiding us toward our ultimate aim of achieving net zero. We’re innovating sustainable solutions, reducing waste, and managing our environmental impact wherever possible. In the meantime, we’ll temporarily offset any remaining emissions when our GHG activities transcend our projected emissions. It’s a gradual process, but we’ve made significant steps in 2022, some of which were carried out in less time than you’d think. Here are three tips you should consider applying now to ensure your 3D printing business is on the right path to a bright and sustainable future.

1) Reducing emissions — should you target emissions in scope 1, 2, or 3?

Before you consider which scope to tackle, you need to undergo a detailed self-assessment to gain an overview of your CO2 emissions and how they’re split over different emission categories. Measuring and analyzing this data will enable you to create a baseline of your current emissions. Next, you’ll need to plan your approach by outlining your company’s sustainability strategy with internal stakeholders to create a sustainability roadmap. After these steps, you’ll have a plan that you can adopt to make significant changes to your business — all based on the analysis of these measurements. “The first step is to measure,” says Jolijn Nijs, Environmental Coordinator at Materialise. “You need a baseline, as it’ll provide you with useful insights. You’ll find it difficult to spot where to reduce your emissions without a proper calculation.”

We first calculated our carbon footprint in 2019, which amounted to 17,800 tonnes worldwide, and we aim to halve this by 2025. We’ve also developed and submitted science-based targets to the Science Based Target initiative, which will be up for approval at the end of 2023.

In 2019, our largest contributors were emissions categorized in scope 2 and scope 3 in the GHG Protocol. However, since switching to renewable electricity in 2022, our largest emitters are now in scope 1 and scope 3. In the past few years, we’ve set up initiatives to reduce them, including creating a carbon budget for air travel, implementing a sustainable travel policy, and reducing our production waste via reuse and recycling. Consequently, we’re now seeing positive results in our latest analysis.

Switch to renewable energy

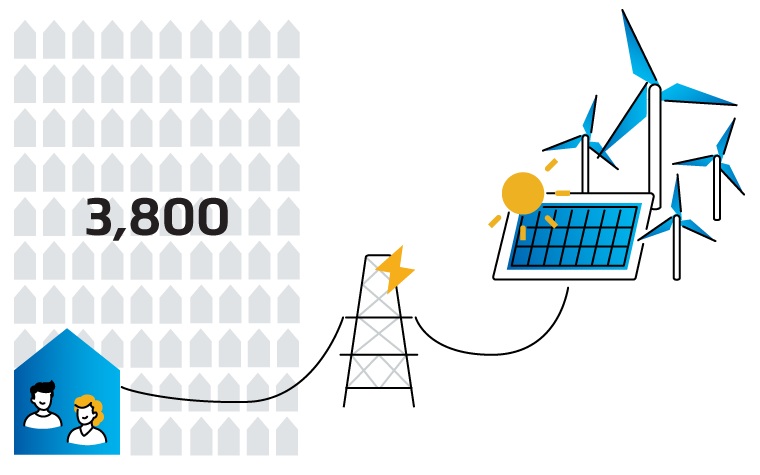

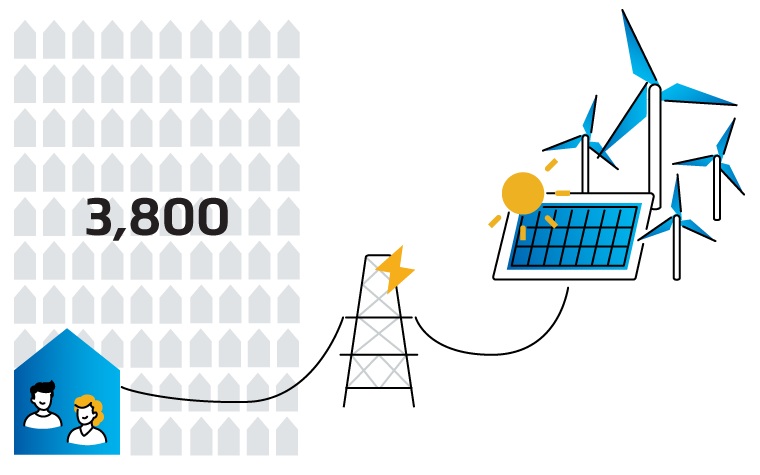

Throughout our worldwide operations, we’ve switched to renewable electricity wherever we had the freedom to select our energy provider. “Switching contracts led to a huge reduction in scope 2,” says Jolijn. Now, all our production facilities are powered by 100% renewable electricity. To demonstrate the impact of this transition, in 2019, we used 13.5 million kWh more non-renewable electricity than in 2022. To put this into context, an average Belgian household consumes around 3,500 kWh annually, so this reduction is equivalent to more than 3,800 Belgian households switching to renewable electricity from 2022 onward — an amazing feat!

Set a carbon budget for air travel

“Setting a carbon budget for air travel — the maximum amount of CO2 you want to generate through business travel, for example — and assembling other projects that tackle lowering emissions is essential,” says Leen Kuijken, Head of Sustainability and Corporate PMO at Materialise.

By the end of 2022, we reached nearly a 44% reduction of our 2019 emissions. Looking at the intensity per employee and per million-euro revenue, we even see a 50% and 52% reduction, respectively. This shows that we have successfully reduced our carbon footprint in absolute terms, even though we continue to grow as a company.

Explore sustainable transport and commuting

In 2020 and 2021, global travel restrictions and increased homeworking led to a drastic drop in mobility emissions for us. Since then, we have introduced travel and hybrid working policies that enabled us to halve our 2019 mobility emissions despite a return to business travel and in-office working in 2022. We also reduced our business air travel by more than 7.25 million km, which equates to traveling to the moon and back about 9.5 times!

“It was eye-opening for us to discover that business travel and the employee commute were two of the biggest contributors in 2019. So, it’s great to see that the policies we’ve put in place have significantly reduced our emissions,” says Jolijn. If employees need to be in the office, promote other modes of transport and provide the amenities to accommodate them.

“In Leuven, we have bike storage facilities, bike locks, and even showers. We’re one of the top employers in our Research/Technology Park regarding promoting sustainable methods of travel for our employees. Around half of our workforce travels by bike at some point during their journey,” she continues.

2) Innovating for sustainability — how long will these initiatives take?

We know the importance of innovation, it’s part of our DNA. However, innovation takes shape in many ways and some forms of innovation can applied sooner than others. Initiatives like switching contracts, creating a carbon budget for air travel, and setting up policies to reduce mobility emissions are changes to processes. Looking at systems or procedures with a fresh point of view and adapting them to fit new requirements is a form of innovation in our eyes. Although, implementing such changes may take several months or more, depending on the scale of your organization. “It does take some time. But that’s partly due to coordinating projects at a global scale,” says Jolijn.

However, fostering a hybrid work culture and sustainable travel methods are concepts that you can adopt immediately. “Switching to renewable energy is relatively easy in most countries, so it could be considered a quick win. But in order to reduce your emissions even further, I’d suggest analyzing your mobility data. That’s a good start. Specifically, giving your employees the flexibility to work from home (WFH) will naturally impact commuting numbers,” she continues.

Spruce up your workplace with quick renovations

Other initiatives may take a long time, mainly performing major renovations and researching new innovations. However, the effects will dramatically cut your emissions. We’ve invested heavily in renovating our production facilities, such as our dedicated finishing area at our HQ in 2022. We’ve also pledged to invest 23 million euros over the next three years to support our team at ACTech with the acquisition of an additional production facility to meet the demands of the automotive industry.

Even though you may not be planning on extensive updates, installing smaller-scale fixtures like solar panels and even checking that your offices are properly insulated, or your heating is at the right temperature could be excellent quick wins in the meantime.

Invest in innovations — both big and small

In 2022, raw materials accounted for one-third of our emissions. Exploring ways of reducing waste is one way to reduce their impact. Moreover, it will be necessary to pursue projects with our suppliers to tackle the impact of our feedstock. Moving forward, the more efficient our production, the lower our emissions. That’s why we’re focusing on innovations and partnerships to make our production processes more sustainable.

For example, our Bluesint PA 12 laser sintering material, made from reused powder, is making headway. With laser sintering, the second most used 3D printing technology,* up to 70% of the powder is downcycled or becomes waste. With Bluesint, this waste powder can be given a second life to print new parts, creating a path toward eliminating waste in 3D printing. As well as avoiding waste, using already-sintered powder in the mix reduces powder-related carbon emissions, offering a more sustainable alternative for rapid prototyping.

Besides this innovation, we are extending the life cycle of polyamide powder by turning unsalvageable waste powder into pellets for use in injection molding. “We partnered with Arkema to bring new life to our polyamide scrap powder — this downcycled powder reduces waste and is an important step towards more circularity. Furthermore, we’ve collaborated with BASF and Sindoh in the past, and we’ll collaborate with more companies in the future. It’s hard to consider where we would be without partnerships,” says Leen.

This is alongside funneling even more of our energy into further innovation within our software and data platform to optimize 3D printing (3DP) process efficiency. For example, the Materialise Quality & Process Control software system helps ensure manufacturing repeatability. Additionally, the AI-powered Layer Analysis tool for metal AM allows manufacturers to quantify defects and identify root causes, reducing manufacturing costs by revealing scrap even earlier in the production chain.

Finally, e-Stage for Metal+ automates support generation to ensure proper stabilization and prevent deformation in builds. It uses easy-to-remove, needle-thin contact points and a flexible grid structure to help remove almost 100% of the excess powder from the support structure and lower risks related to an operator’s health and security. By determining exactly where support is needed, operators can print the first time right without wasting material or time removing unnecessary structures.

We’re also exploring other ways of innovating our processes so that our customers, suppliers, and employees can benefit from more sustainable practices.

“In the near future we want to give our customers the option to choose road instead of air transportation, as not every customer needs parts delivered the following day,” says Jolijn. Plus, we’re discussing alternative, carbon-neutral materials with our suppliers and revising our company car policy to phase out non-electric vehicles.

Major innovations and breakthroughs are challenging to realize in short time frames, but you can start investigating ways of innovating your processes and workflows. Not to mention, investing in relationships with partners now can help push your goals forward.

3) Collaborating for success — how can you get your workforce onboard?

To realistically hit your targets, you need buy-in from every level of your organization: management, stakeholders, and especially your employees. In our case, although we’re fully committed to reducing our 2019 carbon footprint by 50% before 2025 and by 55% before 2029, we understand that certain aspects are not entirely within our control. Nevertheless, having committed employees who are aligned with our goal is key to meeting our objectives. That’s why we’re bringing them along on our sustainability journey.

Show your employees the way

“Setting specific targets like electrifying your fleet of company cars and reducing your internal and business flights adds up,” says Leen. Have an open dialogue with your employees. Make them aware of their habits and highlight how small changes may significantly reduce your company’s CO2 emissions. “Simple actions like telling your workforce that different, and often greener, modes of transport are available is important. Also, traveling within Europe using trains instead of planes makes a huge difference,” suggests Jolijn.

Another idea is spreading the word within your organization: set up campaigns, encourage management to communicate that sustainability is high on your company’s agenda, and give tips to your workforce on how they can make practical, sustainable choices. They’re important advocates; you’ll struggle to achieve your targets without them.

“We’ve put sustainability in the spotlight by coordinating a company-wide Sustainability Day,” says Peter Leys, Executive Chairman at Materialise. “This internal event covered our roadmap and the current and upcoming initiatives we’ve organized to raise awareness, enthusiasm, and engagement within our offices worldwide — allowing everyone at Materialise to understand and get behind our sustainability strategy.”

Sustainability is all about doing it together. So, remember to engage and collaborate with your employees, as well as your stakeholders.

Sustainability doesn’t have to be taxing

Sustainability is a complex topic, and it may seem taxing without the proper steps and resources in place. However, there are things you can do to push your additive manufacturing company’s goals forward. Implement quick wins: switch to renewable energy sources like renewable electricity, rethink policies like mobility and WFH models, carry out minor renovations to your infrastructure, and keep your workforce informed about your strategy.

At the same time, stay focused on bigger, long-term projects that’ll reduce your GHG emissions: establish a carbon budget for air travel, collaborate with partners, and invest in future innovations and processes. Also, set up constructive cooperation with your clients and suppliers, as no organization will be able to reduce its company footprint to zero on its own. And continue to measure and follow up on the results of your actions.

Finally, remember to keep perspective of your company’s situation. Everything takes time, but it’ll be worth it! Keeping this in mind and sticking to a strategy will ensure your company fulfills its sustainability ambitions for the short- and long-term.

*Source: Statista, June 2020

Share on:

You might also like

Never miss a story like this. Get curated content delivered straight to your inbox.