EXPERT INSIGHT

Meet Our Modular Toy Robot at the Family of the Future Event

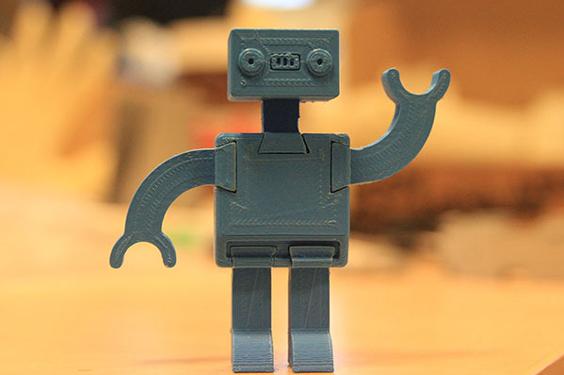

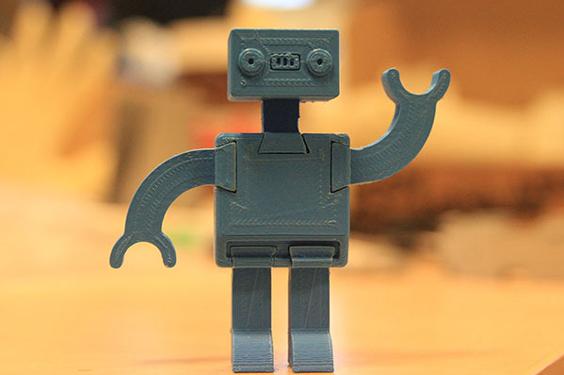

On November 8, we will be taking part in the launch of Family of the Future, a concept organized by Flam3D. It will showcase the state-of-the-art in 3D printing technology, including an overview of available technologies and how they can add value to a variety of different industries. And among the displays will be a 3D-printed toy robot, designed and produced by Materialise!

Flam3D is an umbrella organization which reunites 31 Belgian Additive Manufacturing companies. Above all, they want to stimulate co-creation between companies and spread awareness of the possibilities of 3D Printing.

“Co-creation adds value: what Additive Manufacturing really needs for the future, is cooperation. Beyond the hype, there’s a world in which we must work together – both in- and outside the Additive Manufacturing ecosystem.”

— Kris Binon, General Director of Flam3D

As part of the Additive Manufacturing demos on display during the event, we designed and created a modular toy robot to showcase how families could be able to produce their own toys in keeping with their children’s development or preferences.

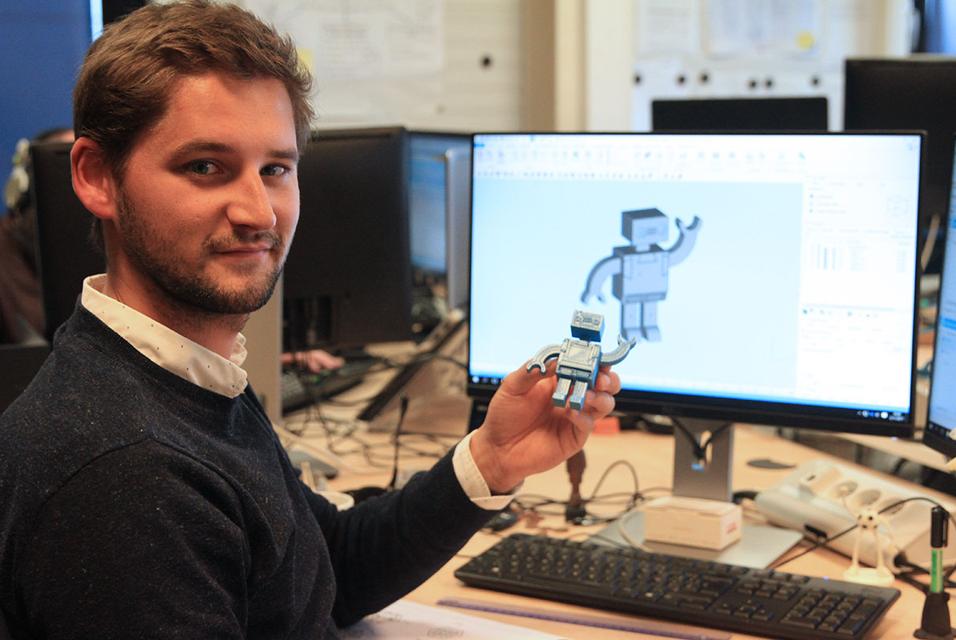

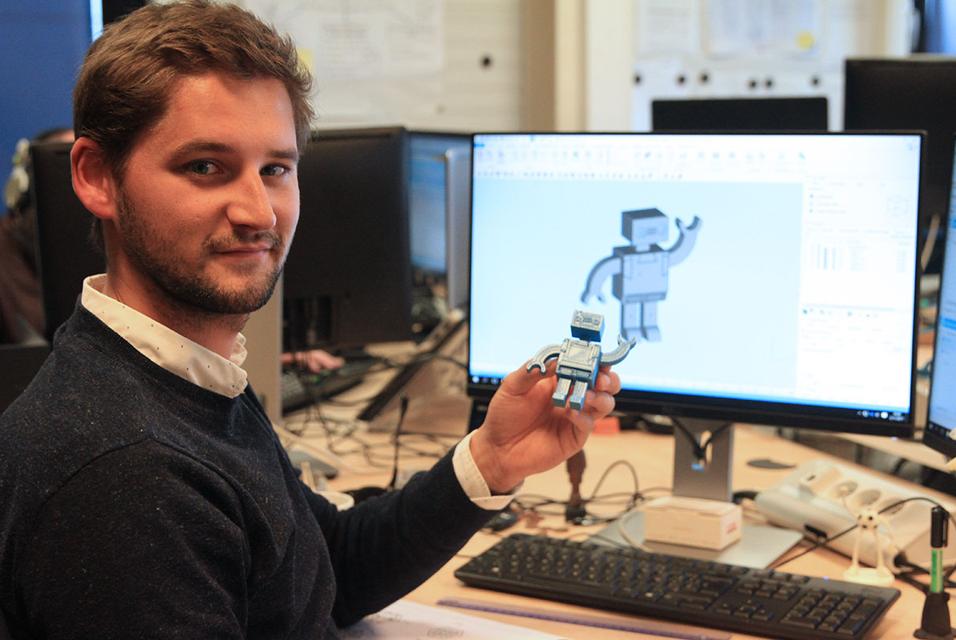

The idea was to create something you could easily print at home on a desktop printer. Nicolas Meiresonne from our Design and Engineering team put together the concept: a small robot with interchangeable, interlocking parts. Children would be able to select and print different heads, legs and bodies from a database – and even add accessories such as a skateboard or a UFO!

The project was printed on a small desktop 3D printer using Fused Deposition Modeling; a technology where a nozzle distributes molten plastic layer by layer. In this technology, prints typically require a support structure during the 3D printing process to prevent overhanging parts from deforming. These supports are built simultaneously with the model, and later removed manually.

In this case, Nicolas and the team designed the parts in such a way that minimal support structure would be needed in order to build them properly – which means the parts are as good as ready to play with once they’re taken off the build platform.

“We wanted to create something which would help children come into contact with 3D Printing in a playful and engaging way. I definitely had a lot of fun designing this particular project – and I hope it’ll even inspire some kids to become 3D design engineers themselves!”

— Nicolas Meiresonne

Share on:

You might also like

Never miss a story like this. Get curated content delivered straight to your inbox.