CUSTOMER STORY

Making a Difference with 3D-Printed Surgical Guides at AZ Monica

3D technology has had a major impact on the healthcare field, offering improved patient care for every case, no matter the complexity. In this article, Dr. Frederik Verstreken, Hand Surgeon at AZ Monica, shares his experience implementing a point-of-care lab, the benefits of ingraining 3D technology — such as 3D-printed surgical guides — into his practice, and a real case where 3D made all the difference.

3D's entrance into AZ Monica

Dr. Verstreken first experienced the power of 3D in patient care during a presentation by another hand surgeon, Prof. Filip Stockmans. Although Dr. Verstreken had no immediate plans to integrate the method into his own work, Prof. Stockmans's success with 3D stuck with him. Later, upon encountering a case where a patient had a malunited forearm, Dr. Verstreken quickly recognized 3D's potential. This particular case would have been very difficult to treat with standard 2D technology.

That's when Dr. Verstreken retraced Prof. Stockmans's footsteps, contacting Materialise to discuss a collaboration on the case. Materialise supported him with 3D planning, surgical guide design, and 3D printing of the guide. "The outcome was fantastic," according to Dr. Verstreken.

From there, he continued partnering with Materialise, and over time, AZ Monica slowly began integrating 3D technology into their facilities. First, in 2010, they acquired 3D planning software from Materialise to complete visualizations and uncomplicated plans on their own. Next came design; the hospital hired an in-house expert to design their guides. And finally, they bought their first printer in 2017, the last step in creating a complete, end-to-end 3D printing workflow in their own lab. Since then, their focus has been on improving and fine-tuning the lab. In 2021, they introduced the Formlabs Fuse 3D printer that uses selective laser sintering (SLS) technology, providing even higher quality output.

Now, the point-of-care lab at AZ Monica is in regular use. The team completes around four to five cases using 3D technology per week, one or two of which include 3D printing.

The 3D difference

So, what exactly made investing in 3D technology worth it? The number one answer is exceptional patient care.

More specifically, the technology has many benefits that ultimately lead to better treatment. Some that Dr. Verstreken finds most significant include:

- Use as a diagnostic tool

- Precise planning

- Expanding on indications for surgery

- Decreasing surgery time

- Reducing patients' exposure to radiation

- More predictable outcomes

Even though they continue to collaborate closely with partners in the industry for complex cases, there are applications where the team sees advantages in having the technology in-house. First, it gives them more flexibility and opportunity to innovate. Secondly, for some indications, they can greatly reduce lead time by not relying on external partners. Financially, the AZ Monica team also anticipates that it will help them save on costs in the long run. And last but certainly not least, it's gratifying. "We feel it's very rewarding and even helps us avoid burnout," shares Dr. Verstreken. "This is really fascinating technology. And when we see the results, it stimulates us to continue on that track."

Mending bones with 3D technology

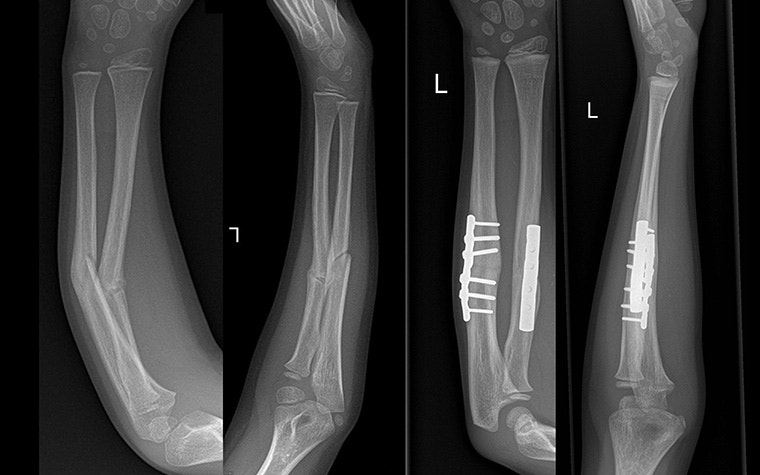

Dr. Verstreken has incorporated 3D technology into his practice for 14 or so years now, and many of his cases have benefited from 3D planning and printing. One that stands out is a seven-year-old child who had broken their arm in three places. Traditionally, just a cast would be enough to treat this type of break. However, for this patient, the cast mended the bones at an incorrect angle.

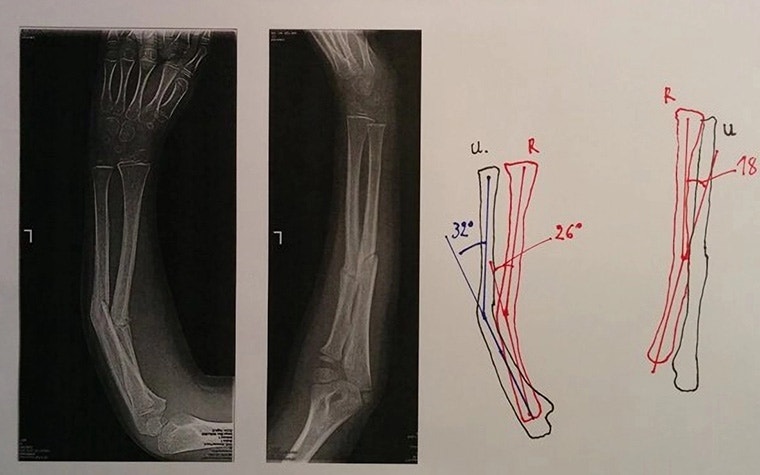

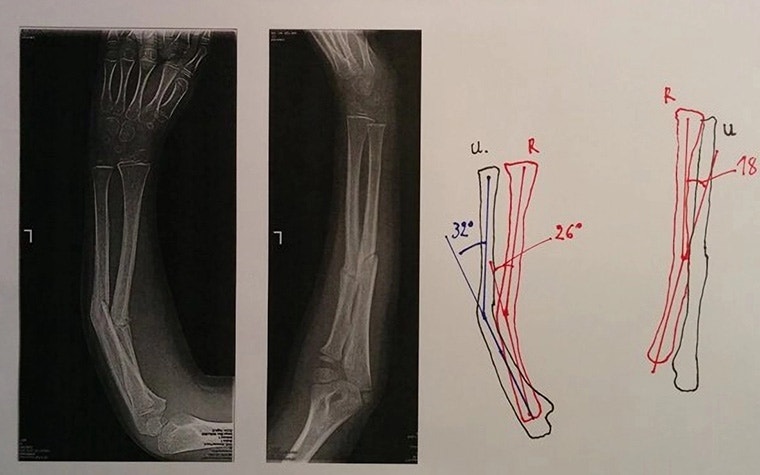

Typically, surgeons actually planned for this operation using pen and paper. "Maybe even today, this is the way surgeries are planned," explains Dr. Verstreken. "Taking a piece of paper, drawing the outlines, and looking at the correction of the angles. Then you go into the operating room and try to do the best you can to restore the anatomy. But it's not as easy as that."

3D offers so much more than that. Drawn diagrams only provided a way to address angulation. By planning in 3D, the surgeon can manage malrotation as well as the lengthening and shortening of the bone in his preprocedural plan. "We really want to make sure that we're restoring the anatomy as precisely as possible," says Dr. Verstreken. "And that's where 3D technology can be extremely helpful."

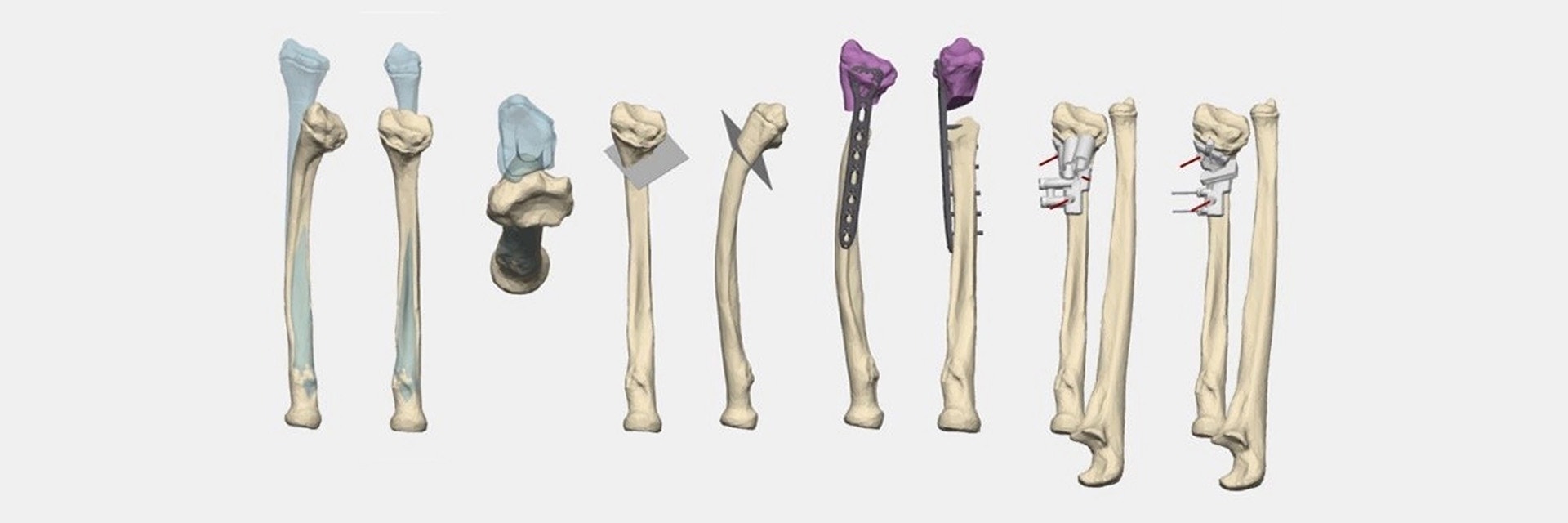

The process began by compiling CT scans of both arms into a 3D visualization. From there, Dr. Verstreken compared the mirrored 3D image of the healthy forearm with the abnormal forearm. And next came planning. He conducted a virtual surgery with the 3D visualizations, deciding where to lengthen and shorten bones, how exactly he should cut the bone, and where to insert the graft.

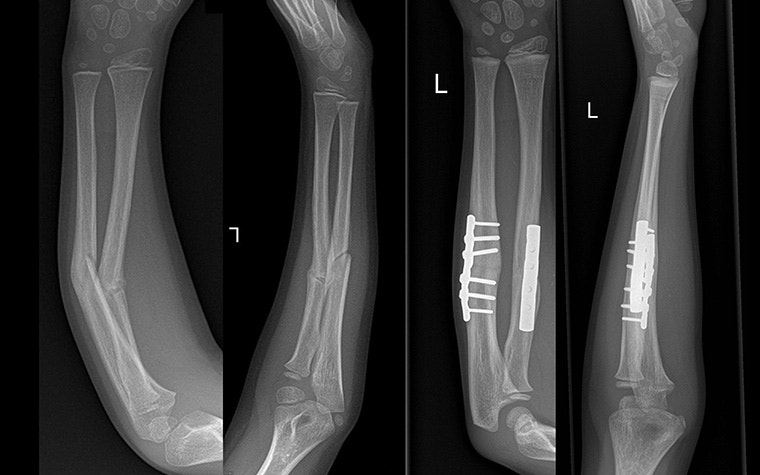

Based on this plan, the hospital's clinical engineer designed and printed the surgical guide. And by the time he stepped into the operating room, it felt to Dr. Verstreken as though it wasn't his first time completing this surgery. After placing the guide on the bone, it was smooth sailing.

"Once the guide is in the right place, it becomes fairly easy surgery because you know where to drill, you know where to cut," explains Dr. Verstreken. "And those [where to lengthen and shorten bones] are things that we would never be able to plan so precisely with standard two-dimensional X-ray."

Tips for hospitals implementing point-of-care labs

When hospitals like AZ Monica find success in building a point-of-care lab, Dr. Verstreken finds it crucial to share advice, stories, and questions within the community. Navigating regulatory requirements and hospital administration can be tricky, so we can all learn from each other.

If you'd like to explore introducing a point-of-care lab into your hospital, Dr. Verstreken suggests beginning by getting colleagues interested. Discuss with colleagues from other departments how a lab could benefit all of your teams. 3D technology can have a major impact on many fields, and it's a great opportunity to split costs among departments.

Next, make sure to stay compliant with regulations. This can pose a challenge, so Dr. Verstreken advises speaking with others who have successfully integrated quality management systems into their labs and learning from their processes. Materialise also offers a training course on setting up a quality management system with experts that can guide you through the process.

Because designing guides is also no simple task, we recommend following proper training to ensure a successful outcome. To make this type of training more accessible, Materialise created a flexible online course consisting of two levels that teach attendees best practices for using Materialise Mimics. The first level, the Fundamental Course, covers topics such as segmenting medical images to create 3D models. The Design Course takes it a step further, covering the design and development of patient-specific medical devices and products. By learning the ideal processes and methods in courses such as these, hospitals can streamline training for point-of-care lab staff.

Of course, hospitals also need to justify why an in-house lab is preferred. Collect arguments that prove why it's such an asset — AZ Monica suggests including shorter lead times, accessibility, and flexibility.

And finally, great team collaboration is a must. Set up a close working relationship with the radiology department. "The 3D work all starts with good quality imaging," explains Dr. Verstreken. "You'll rely on the radiology department, so it's important to have them on board." Another critical expert for the lab is the clinical engineer. They are often at the center of 3D labs, so it's crucial to have a reliable, motivated professional in that role.

Ready to get started? We hope these tips and Dr. Verstreken's story help you on your way to setting up a 3D printing lab at your hospital.

L-103253-01

Share on:

You might also like

Never miss a story like this. Get curated content delivered straight to your inbox.