CUSTOMER STORY

3D-Printed Medical Manikins Become Effective Training Aids for COVID-19 Swab Collection

In Singapore, 3D printing has proven to be useful during the COVID-19 pandemic, with its ability to move directly from design to on-demand production for essential medical supplies like ventilators, face shield frames, and other medical devices. One of the perfect examples is the case of 3D-printed medical manikin developed by Creatz3D & AuMed, which has become effective training aids for respiratory swab collection during the COVID-19 pandemic.

Headquartered in Singapore, Creatz3D is a leading 3D printing solution provider, whilst AuMed is a bespoke medical simulator company, a subsidiary under the main arm of Creatz3D. The company has worked with various institutions in the healthcare sector in creating realistic and accurate models for pre-surgical planning, procedural simulation, medical product demonstration, or customized for used in medical education. In this blog, we sit down with Sally Chuen, Creatz3D’s Sales and Applications Manager, and Catherine Chia, AuMed’s Senior Biomedical Engineer, who were involved in the project of designing and 3D printing the medical manikin that could support the trainings for respiratory swab collection.

Why is there a need for Medical Manikin as training aids for respiratory swab collection in Singapore?

As Singapore reached the record-breaking amount of the highest per capita COVID-19 infection rate in Asia with 34,800 positive cases, the government initiated a mass testing of 323,000 foreign workers to curb the rising infections. By doing so, the daily testing capacity will need to ramp up from 8,000 currently to 40,000. Hence, there is a growing and urgent need to train more swabbers to support and increase swab testing efforts in these unprecedented times.

Swab tests are an integral part of the fight against COVID-19 as it determines whether a person is infected. Typically, it involves the insertion of a swab through the nasal cavity or mouth to the back of the nose and throat, and swabbing the walls by gently rotating the swab to collect specimens.

With an increase in demand for the respiratory swab testing, selected civilians who often do not possess medical knowledge were hired to perform the procedures. Although training sessions for respiratory swab collection are conducted by healthcare professionals, there are many challenges in said process. Step-by-step training videos are widely used, but not effective as they lack the hands-on experience. Training with a medical manikin is the best option but existing ones in the market lack representative features to facilitate the execution of three essential procedures: nasal mid-turbinate swab, nasopharyngeal swab, and oropharyngeal swab.

In short, the medical manikin needs to have all the relevant anatomical features to support the execution of the three swabbing procedures, but also replicating the realistic texture and appearance of the human soft and hard tissue. The combination of all these elements allows the learners to practice and simulate the procedures under very realistic conditions.

What are the challenges in meeting the user requirements?

There are three main challenges, with the first one being that where the specific anatomical features requested by the users were not easily attainable:

- All the essential respiratory anatomies that are needed for teaching nasal, nasopharyngeal, and oropharyngeal swabs

- The anatomical model must be in an open-mouth position

- The dimensions must be compatible with the medical-grade swabs used

- The tongue should bounce back when the depressor is lifted

The second challenge was that the user did not have the CT & MRI DICOM data for the design of the manikin. This added tremendous amount of pressure on our team as normally, we produce 3D-printed replicas of an organ or tissue derived from DICOM sets provided to us by the user. However, in this project, not only we have to treasure hunt for suitable DICOM data from AuMed’s DICOM library, we also need to combine the data from several DICOM sets (and from different modalities) into one in order to create the required medical manikin.

Last but not least, since it’s for efforts against COVID-19, the users were expecting quick in turnaround time.

Can you describe the process of designing the medical manikin?

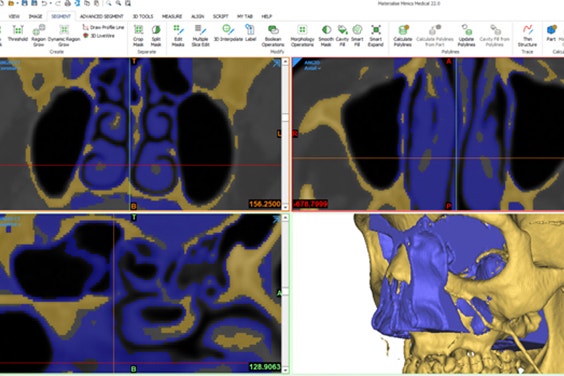

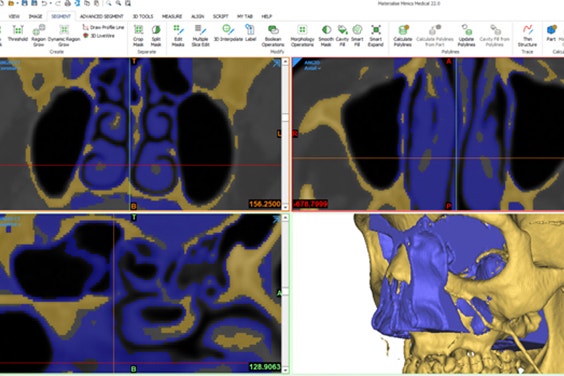

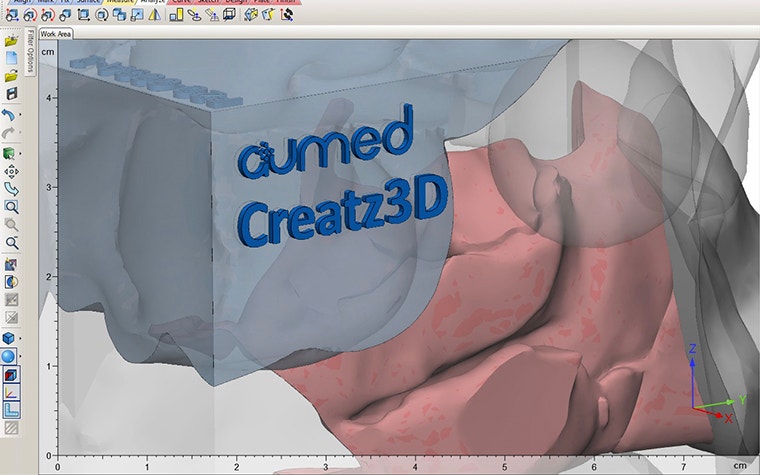

We have been using the medical version of Materialise’s Mimics Innovation Suite (MIS) for many years and it’s our choice of medical image-based engineering software to use for the design of the medical manikin. Our team identified a sets of suitable DICOM data from different modalities (both CT & MRI) and segmented the bone structures and soft tissues that formed the nasal cavity and part of the pharynx with Materialise Mimics.

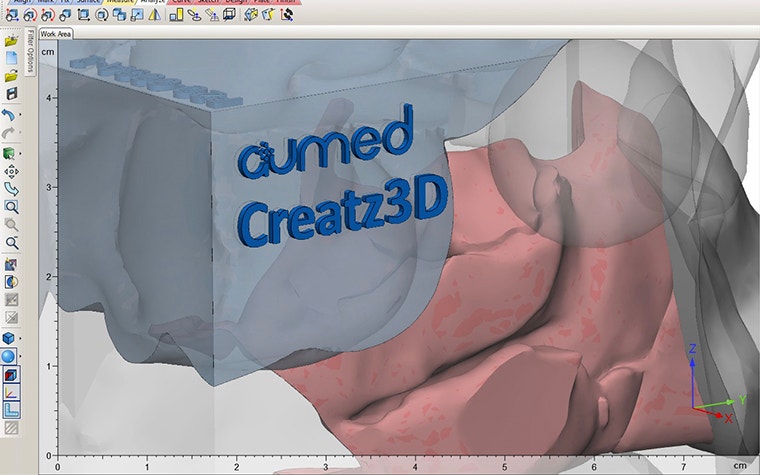

We used Materialise 3-matic to reposition and scale various 3D anatomical models into their respective intended positions in one “hybrid” human head. Feedback from healthcare professionals helped to ensure the unity of the isolated anatomies was done accurately in the software. Lastly, the missing gaps in the space containing the organs and tissue were filled up with seemed-real surfaces into a single anatomical model.

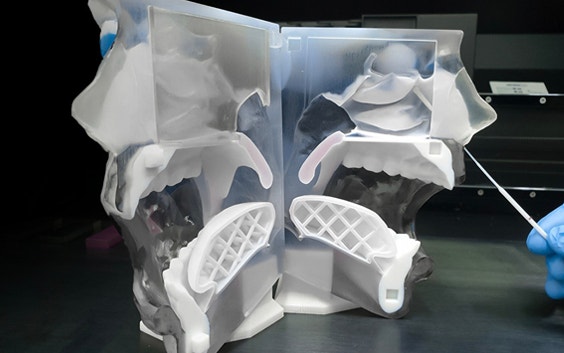

To aid the learner's understanding of the procedure, the anatomical model is designed in cross-sectional format which can be detached and recombined easily.

On top of reconstructing the 3D anatomical model oriented complete with anatomically realistic bone, skin and muscles which are now ready for 3D printing, we used Stratasys J750 to enable multi-material and multi-color in one print which differentiate parts of the anatomy as well as simulating the soft tissue.

What is the hardest part in the entire design process?

Making the assembly ready for multi-material additive manufacturing (AM) was by far the most challenging. We needed to optimize the design for additive manufacturing which comes with its own engineering design principles. On top of that, the technology and 3D printing material we used had a spectrum of specific properties which the digital design must account for (e.g. tolerance needed for flexible component like the tongue on the rigid mandible during 3D printing). Here, we used the design and fixing features in Materialise 3-matic extensively and rigorously, making sure all the connections between the anatomies and connectors between the assemblies were well defined and made, before we export them for 3D printing.

What is the impact of the Mimics Innovation Suite to make it a success?

Mimics Innovation Suite is indeed a software suite meant for medical organic 3D modelling, especially when you need to work with data derived from CT or MRI. With its combined strength (Materialise Mimics and Materialise 3-matic) in surface modelling for these medical data, we can effortlessly control our files down to the units (triangles) of the organic 3D anatomical models, which often cannot be described with simple geometry (e.g. spheres, rods, etc.).

How long does it take from design to print?

Our team was able to create life-size manikins specifically for respiratory swab collection training at a very short span of time, one day for designing and three days for 3D printing and post-processing 3D printing, as compared to a few months with traditional manufacturing.

What is the user experience of the 3D-printed medical manikins?

The 3D-printed manikins presented opportunities for the swabbers to be trained more effectively alongside the existing training materials and arrangements (training slides, hands-on sessions, etc.). The manikins were real-life size, perfect for standard medical-grade swab sticks to be used. It was observed that there were increase of interactions between the trainers and trainees by referring to the same tangible 3D-printed manikin during the training.

The presence of all crucial anatomies (e.g. turbinates, pharynx, and uvula) in the 3D-printed manikin, enable the users to have good observation and understanding of the nasal, mouth, and throat internal structures which are otherwise not possible with a real person being swabbed. Also, many users were impressed by the spongy tongue for simulation with a tongue depressor!

Any last words?

Developed in response to training needs for COVID-19 identification, this crisis has highlighted how Medical 3D visualization and printing is capable of stepping up to adapt to the needs of users in producing essentials on demand with a short turnaround time.

Share on:

You might also like

Never miss a story like this. Get curated content delivered straight to your inbox.