EXPERT INSIGHT

10 Years of phits Orthotics: From Belgium to the World

As 3D printing continues to advance, so too do our 3D-printed orthoses. Over the last 10 years, we’ve been lucky enough to work with a great team of experts, internally and externally. Today, they share their knowledge and experience from the journey so far.

2024 was a big year for phits orthotics. We celebrated the 10th anniversary of their launch, introduced exciting improvements to the 3D-printed bases and footscan software, and continued to set the standard for foot health at events around the world. Our proven solution, reputation as a reliable partner, and high-quality orthoses have seen us make a difference in countless clinics — and we’re still getting better year after year.

Reaching this point has been a journey. And it's one we've shared with distributors, medical professionals, patients, and some wonderful people behind the scenes here at Materialise Motion.

Naturally, there's no better crowd to speak to when the time comes to reflect on it all — so we brought them all together, and that's exactly what we did.

2014: The early days of phits orthotics

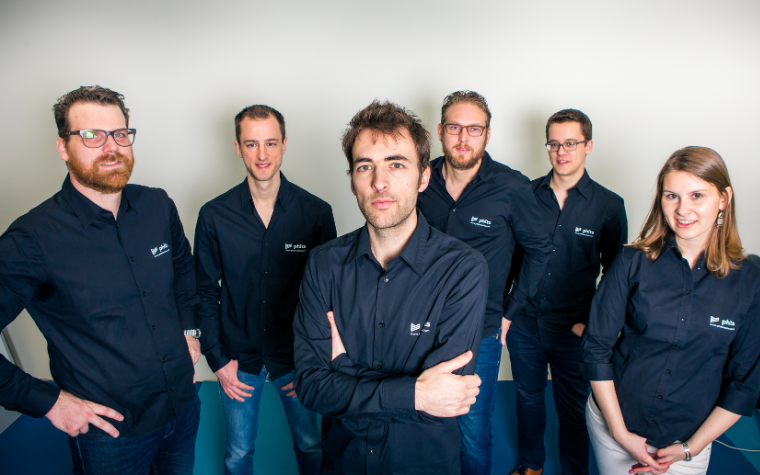

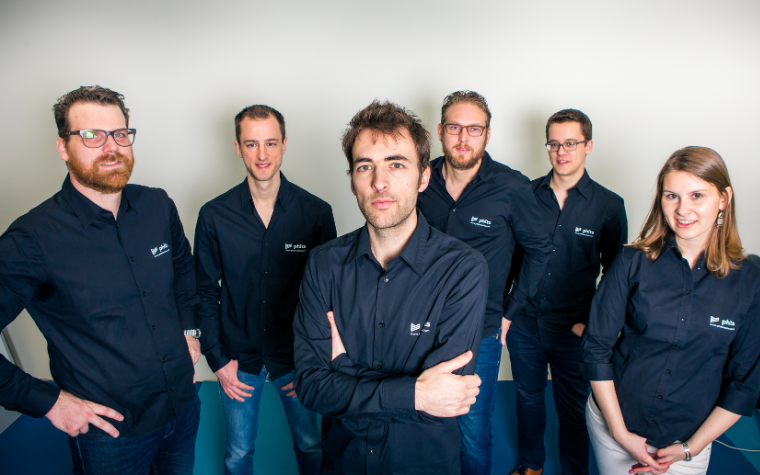

Understandably, much has changed since the phits orthotics journey began in April 2014. Dennis Vandenbussche, former CEO of RS Print, and Tom Peeters, former Market Manager at Materialise Motion, have some fond memories of the early days. They both had a big part to play in laying the groundwork, after all.

"Let’s say it was the product that convinced me to join RS Print in early 2015," says Tom. "The technology was definitely ahead of the marketing at that time. One of the first things I wanted to tackle as a sports marketer was rebranding the company. We settled on the visual identity very quickly, and I’m pleased to see that the logo is still used today, albeit now in Materialise’s colors. The name was a different matter!"

"We were looking for something intelligent, ambitious, or all-encompassing, but what we missed was ‘catchy.’ Ultimately, we agreed the name should reference physicality and fit, and that led us back to phits. Ten years later, it’s a well-known name in the sector, and I’m still very proud to have contributed to that."

Other hurdles required a more hands-on approach.

"Very hands-on, I’d say!” recalls Dennis. “When we first started, our partners at Runners’ Lab finished every insole. I had no background in doing that, but I spent a day there learning how to glue orthoses, took home a pot of glue, and the job passed to me. I started with insoles for a small group of internal testers and used the feedback to optimize our product for the big launch."

The journey to market

Once the 3D-printed orthoses hit the market, sales quickly took off, driven by their effectiveness and the positive response from customers.

"It didn’t take long at all, actually. Once we started selling in-store, everything went through our OMS, and I would get an email every time someone placed an order — normally on Saturdays when the team at Runners’ Lab scheduled appointments for the new 3D-printed orthoses,” says Dennis. “First 3 per week, then 5, then 10; at some point, we were averaging 5 per day, and it’s clear to see how it’s grown since then."

That quick success can be attributed to addressing a real need in the market. By combining 3D printing technology with footscan pressure measurements, clinicians gained access to a highly accurate and effective solution for their patients — and a wholly new way of working.

“The big idea behind phits was to transform the traditional, labor-intensive way of making orthotics. I don’t know if it felt that way to Dennis when he was busy gluing them in his basement, but the method really makes a difference,” says Sander Van Nieuwenhoven, Product Owner of phits at Materialise Motion. “Combining 3D printing and data from footscan pressure measurements leads to highly accurate orthoses and more effective solutions for patients. The market just reacted to that."

2020: RS Print merges with Materialise

RS Print’s integration with Materialise in 2020 marked a significant milestone for phits. This acquisition allowed for accelerated development and innovation, such as the launch of phits+ in 2022. Gaining access to Materialise's 30 years of experience in 3D printing was a major advantage.

"The journey really started at OT World in 2014, not too long before I joined. We were the first company to present 3D-printed orthoses, and we’re still pioneers in that sense. We introduced the phits brand in 2016 and were acquired by Materialise in 2020. That was a significant leap forward because we could accelerate our developments, like with the launch of phits+ in 2022," says Sander.

An early model of phits orthotics, printed in 2015, and the latest model, phits+.

"Gaining access to over 30 years of 3D printing knowledge and experience is a major advantage over the competition. It means we can continuously innovate and improve our products. For example, with the developments we made for the phits+ orthotics, the backend flow is now fully automatic. When the process runs as smoothly as possible, we can guarantee a reliable service for our customers. As soon as a customer places an order in the software, the orthoses are made without any manual intervention and ready for production on one of our 3D printers within about 10 minutes."

Why insoles — and why 3D printing?

For Fried Vancraen, founder of Materialise, the decision to combine his 3D printing expertise with the knowledge of RSscan was motivated by the needs of his family.

“My family and I have all worn insoles for years, but we could never find a perfect pair. And I wanted my family to have a pair that fit them perfectly, that were comfortable and durable, and that let them wear the shoes they wanted to wear,” he tells us. “I knew that 3D printing could help, but it wasn’t enough on its own. It was when we combined 3D printing with the pressure plates of RSscan that we saw real progress. So, together, we created a new company — RS Print.”

It was a special combination and, as Sander said, one that changed everything.

“It was a first in the industry. Now, instead of only measuring static information like traditional methods, we could suddenly see the load-bearing and dynamic behavior of a foot. Using that data, we could design an orthotic with the corrections that the person needed and create it exactly through 3D printing,” he recalls.

“The result was phits, of course: an insole designed for the unique way that they moved, as well as for their lifestyle. Whether they needed them for everyday walking or running, skiing, or other sports, that’s what they would get.

But more importantly, it’s what allows all the clinicians who rely on our products to provide the perfect treatment plan for their patients. We designed this software and these orthoses to help them do that.”

“phits have been a game-changer for my business over the past decade. The continuous innovation and improvement in comfort and support have made them the best product on the market. I am thrilled to celebrate this milestone and look forward to seeing how phits will evolve even further in the years to come.”

— Larry Chase, Phitsjax

From Belgium to the world

Today, phits orthotics are delivered, used, and loved all over the world. Since 2016, production has taken place in both Belgium and the United States, ensuring shorter lead times for customers everywhere. Thanks to distributors and healthcare practitioners, those customers are found across Europe, Asia, the United States, and the Middle East.

The response has been incredibly positive. phits’ durability, comfort, and customization options are widely praised, while footscan’s automation and ease of ordering have saved time and improved efficiency in countless practices.

"Groep Sam ventured into the world of 3D-printed orthotics 10 years ago. We believed in the product and the company — and certainly that 3D was the future,” says Eef Lantin, Physiotherapist and Co-Founder of Groep Sam. “Two factors really sold it for us: firstly, the durability. phits last twice as long as regular insoles. Secondly, we saw a major advantage in the ability to convert the pressure measurement from a dynamic analysis into customized insoles."

Others have witnessed the rise of phits for even longer. Philippe Vermaelen, R&D & Prolab at Runners’ Lab, was one of the first to try the insoles for himself and has seen them come on leaps and bounds ever since.

“As Dennis alluded to, I’ve been lucky to experience the development of phits from the get-go,” he tells us. “In the beginning, it was mainly a 3D-printed alternative for the handmade insoles that we still make here at Runners’ Lab. Now it’s clear that phits are a fully-fledged option with a lot of great benefits, like Eef said.”

The importance of relationships

Of course, it’s not just about sales. Strong relationships between Materialise and its partners have been essential in driving innovation. Distributors and end-users act as ambassadors, helping to reach and support thousands of patients globally, and it doesn’t end there. Ongoing collaboration with partners like Gait and Motion Technology (GMT) is still shaping phits’ future.

"It’s key, not just for the relationship, but for the development of phits. GMT established the UK phits Clinical Advisory Panel (PCAP) to provide ongoing expert clinical feedback to drive innovation and change. Materialise has always been open and reactive to that feedback," says James Evans, Director of Client Operations at Gait and Motion Technology.

Gait and Motion Technology (GMT) have brought phits to clinicians far and wide, including the UAE

Scott Barton, Managing Director at Gait and Motion Technology, agrees.

“Our team has worked with footscan for almost 20 years — it’s always been an essential tool for us,” he tells us. “When we officially launched GMT in March 2018, we actually stepped away from our previous lab to pioneer phits in the UK, Ireland, and UAE, so we obviously believed in the product. We’ve always strived to optimize biomechanical assessments in the clinical world by providing best-in-class objective data that the eye cannot see, and phits deliver that every time.

Seven years on, we’ve established a network of over 450 Gait and Motion Clinics’ partners, each offering footscan and phits to their local communities.”

Importantly, it’s a relationship that goes both ways. The Materialise Motion team is always on hand to offer support to new and existing partners.

“I’ll often work closely with new customers and design their first orders together. It’s a great way to help them gain confidence in the software, explore all the possible solutions, and create a more suitable design,” says Annouk Verluyten, Account Manager at Materialise Motion. “They seem to really appreciate that I can use my own experiences to teach them more about insole design, which is where the training sessions come in, too.”

Continuous improvement

The honest feedback and ongoing relationships have led to important updates to the orthotics and the software that help keep phits at the forefront of the market. End users and distributors have noted advancements in design, corrective options, and overall functionality.

"I think both the orthotics and the software have continuously improved. The orthotics are even thinner these days, with more options for width and other adjustments. The design wizard is incredibly intuitive, and it’s easy to generate a design quickly," says Philippe.

"I agree; it’s fantastic how well they’ve developed,” enthuses Pia M. Kristensen, Podiatrist and Founder of Storvorde Fodterapi. “When I first started using them in 2015, there was a good range of corrective options, which was important. I liked all the choices, and I could still decide what corrections to include for myself. Over time, they’ve improved even more — for example, the satisfaction of being able to move a T-form or teardrop. The new base is lighter, it works better in shoes, and the patients are more satisfied than ever. This ongoing development gives us the opportunity to make our insoles the best and stops us from switching to other products.”

An orthotic for everyone

With so many improvements over the years — new bases, additional correction options, and the launch of automated patient reports, just to name a few — phits has continued to be a leader in the industry by appealing to different needs.

"For me, it’s how quickly we can create insoles,” says Eef. “The system is also designed in a way that lets us clearly explain to our patients what their gait pattern looks like and how we can alter it with orthotics."

"I want to highlight individuality,” adds Pia. “Being able to make an individual design for each patient — even for each foot — and having many options for different shoes is very helpful. They’re suitable for all patients, including those with diabetes and arthritis, for adults and children."

But perhaps what helped phits grow so quickly is that these benefits are available to all. Regular people can access the same treatment as elite athletes performing at the highest level.

“I’ve provided more than 6,000 pairs of phits to my customers. Among them, more than 1,000 customers are elite sports players, including seven medalists from the Paris Olympics,” says Dr. Kyounghoon Chai, CEO of Alchemaker, a valued distributor in South Korea. “They are really satisfied with the pain relief and increased stability in terms of balance management.”

Fried Vancraen meets Dr. Kyounghoon Chai while visiting Alchemaker in South Korea.

GMT’s George Cummins echoes that sentiment.

"We’ve also had tremendous success in elite sport,” he says. “Dozens of British and World Champion athletes, such as Dan Studley and Charlotte Purdue, now use phits on a daily basis. But so do thousands of regular people in their day-to-day lives."

That accessibility extends to our interviewees. Fried, Pia, Dr. Chai, Tom, Sander, Annouk, and the GMT team wear phits on a daily basis; Philippe has a pair designed specifically for cycling. It’s a lot easier to believe in a product and share those benefits with end-users when you experience them for yourself.

“Some of the most common questions our customers ask are about comfort, fit, effectiveness, durability, compatibility with shoes, the adjustment period… anything about living with them,” says Annouk. “Wearing them every day helps me answer those questions effectively, and that increases our customers’ confidence in the product.”

GMT works with many British athletes, including marathon winner Charlotte Purdue and distance runner Dan Studley

2024: Looking to the future

As phits orthotics continue to evolve, the focus remains on providing clinicians with the tools they need. Integrating new technologies and continuously improving the product will ensure that phits stays at the forefront of the market.

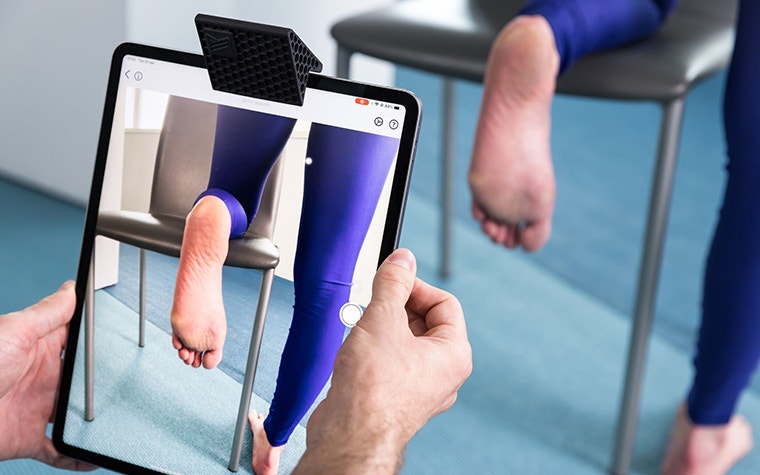

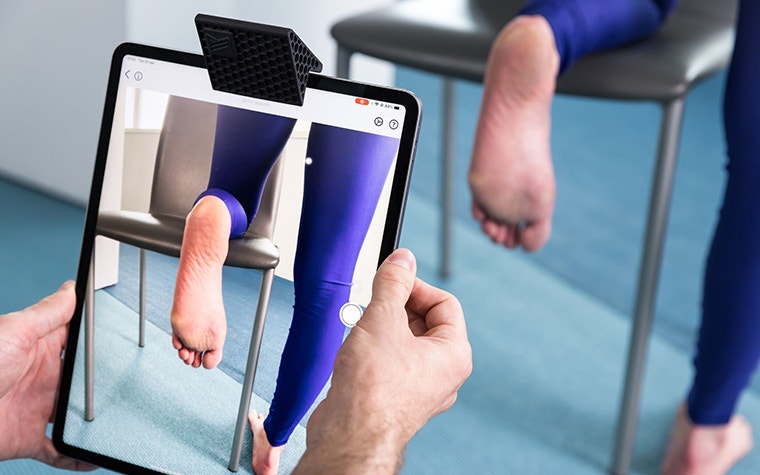

"For me, it's all about continuing to provide our customers with the tools they need to better help their patients. Our mission is to support clinicians so they can help more people live pain-free,” says Sander. “One way we’re looking to do that is to further integrate SAM, our 3D scanning app. The combination of both foot pressure measurements and a 3D scan of the patient's foot gives experts more insight into any issues."

Beyond that, there’s a clear focus on improvements that will improve the quality and ease of design within the software. And yet again, they’ll come through collaboration with experts in the field. It’s something that Sam Van Rossom, Biomechanical Research Engineer at Materialise Motion, is excited about.

“With Mobilab&Care, we are developing an evidence-based framework to connect the different pathology characteristics to insole concepts and designs,” he tells us. “This framework groups existing scientific evidence and will allow clinicians to receive automatic treatment options based on characteristics observed in the patient.”

“But we can go a step further. We’re working on setting up AI models to recognize the specific gait deviations in the plantar pressure pattern. It will allow footscan to automatically detect any deviations and propose the relevant correction automatically, all while accounting for the preferences of the individual clinician.”

“We also developed a modeling workflow alongside KU Leuven that allows users to simulate the effect of an insole on their patient’s gait and pressure pattern before it’s even printed,” Sam continues. “By creating a virtual twin of the patient, a clinician can simulate the effect of several potential orthoses on the gait pattern and then pick the one that predicts the most optimal result.”

And the work doesn’t stop with the software. The team continues to innovate throughout the entire workflow. Everything from the phits orthotics themselves to the production process is constantly under evaluation, with new ideas bringing new improvements.

“We want to guarantee optimal design and material properties to support the constant loads patients experience during their day-to-day activities while maintaining the supportive strength,” he concludes. “In collaboration with KU Leuven, we are setting up finite element modeling workflows that allow us to simulate the effect of design changes on the mechanical behavior of our device. It means we can make faster progress when introducing new designs.”

Here's to another 10 years

Helping clinicians give their patients a healthier, more comfortable lifestyle has driven everyone at Materialise Motion to reach this point — and it’s a motivation that hasn’t gone away. The ambitions that Sam and Sander mentioned extend throughout the team and have everyone looking forward to what the next decade has in store.

“Being part of a company that leads in technological innovations in healthcare is incredibly motivating,” says Annouk. “Seeing the positive impact that phits can have on people's lives, such as relieving pain and improving mobility, is so rewarding. Building and maintaining strong relationships with customers and clinicians is an important part of making that happen. We all look forward to hearing even more stories of patients living a healthier and better life thanks to phits.”

Share on:

You might also like

Never miss a story like this. Get curated content delivered straight to your inbox.